Maximo CMMS: What It Does, and Who It’s for

The use of Enterprise Asset Management (EAM) and Computerized Maintenance Management Systems (CMMS) has dramatically improved operations for businesses across all industries. These software platforms can be integrated with existing software tools and hardware components such as asset tags, equipment tags, and inventory control tags and labels to create a comprehensive solution for tracking important assets and work activities.

Among the dozens of offerings in the market, IBM Maximo CMMS has emerged as a leader in the space.

In this post, we’ll introduce IBM Maximo and talk about the core features and benefits of this powerful software platform. We’ll also share some useful resources within the Maximo community and talk about how the software can be used to improve the quality of business processes. Many features of EAM and CMMS platforms overlap between different vendors, but it’s always best to seek out an option that’s adaptable to your specific needs.

Screenshot via IBM Maximo

Maximo is an Enterprise Asset Management (EAM) platform designed to support the tracking and upkeep of assets throughout their entire lifecycle. This system also has extensive capabilities for managing maintenance work for assets, with several features that overlap with Computerized Maintenance Management Systems (CMMS).

You will often find Maximo referred to as both an EAM and CMMS due to its wide range of features. Any asset can be tracked using Maximo including equipment, buildings, and vehicles.

Businesses have three different options when deploying the IBM Maximo software suite.

Many businesses implement IBM Maximo to streamline their maintenance and asset management capabilities. In addition to improving performance, Maximo can also be used to consolidate several unique workflows into a single software package. This enterprise-level support is one of the main reasons for choosing IBM Maximo as compared to other offerings.

The core features of IBM Maximo include:

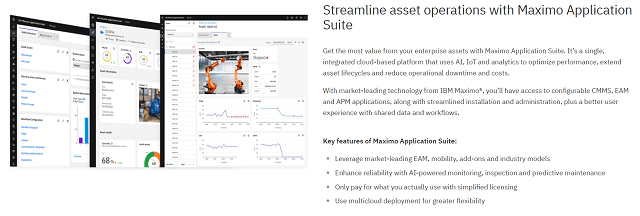

Screenshot via IBM Maximo

Data shared by IBM shows that its Maximo software solution has the potential to reduce labor, inventory, and equipment costs by 10-25%. Much of this benefit comes from efficiencies that can be achieved using the software through streamlined workflows and advanced features.

This includes support for advanced asset management techniques such as reliability-centered maintenance and predictive maintenance.

Companies can also use Maximo to review their critical business processes using the integration with IBM Watson Analytics. These advanced reporting features create a powerful business management framework that delivers unique insights based on reliable data collection practices.

IBM Maximo CMMS has applications in most industries and is an essential resource in the manufacturing, transportation, energy, and government sectors. Given the widespread deployment of Maximo, you’ll find several groups and organizations dedicated to sharing knowledge related to the platform.

A few current examples include:

IBM Maximo is an excellent choice for a CMMS/EAM due to its large number of features and flexible deployment options. With an active community of users around the world, IBM Maximo has also become an important resource for business operations experts.

The tools included with Maximo give any company the opportunity to find innovative ways to improve operations while creating greater value for employees and customers.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer to plan a successful asset tagging project for any maintenance tracking or facility management system.