Inventory Control Tags and Labels

Track your assets to keep operations running smoothly.

The Foundation For Greater Efficiency And Streamlined Processes

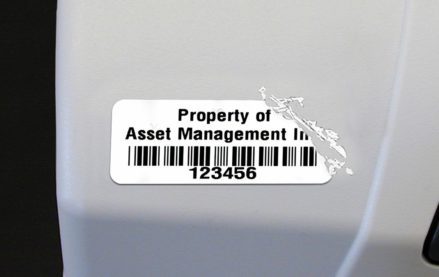

Camcode’s inventory control tags and inventory labels are designed to simplify inventory management. From boosting inventory count accuracy to identifying inventory assets, tracking inventory, and more, inventory control tags provide the foundation for greater efficiency and streamlined processes. Camcode will help you custom design the right label for your various applications. Easily monitor inventory, keep stock levels optimized, and avoid lost inventory with inventory control tags and inventory labels from Camcode.

Camcode also offers comprehensive, on-site inventory management services from an experienced, industry-leading team. If you need to improve your inventory control processes, conduct a physical count for year-end inventory or budget reporting, or implementing an inventory management system, learn more about Camcode’s tailored services.

Get a Free Asset Label Evaluation Kit

Request a free asset label sample kit today and we will send you a kit to test our extremely durable labels in your own operating environment.

Explore Our Most Popular Asset Labels

Find the most durable, custom-designed labels and improve the management and tracking of your assets. Don’t see what you need? Our product development team is on standby to design and build your perfect label.

Industries That Use Inventory Control Tags

The average layperson often thinks of retail operations and warehouses when they hear the word “inventory,” but the reality is that many businesses across nearly every industry have some form of inventory that they must procure, store, and manage — even service-based businesses often maintain an inventory of replacement parts for machinery or supplies needed to provide services.

Why Do You Need Inventory Control Tags?

Inventory management is a major pain point for many organizations, with outdated processes and manual documentation slowing down progress and introducing inaccuracies. Inventory control tags make it possible to automate many inventory processes that would otherwise be time-consuming and inefficient.

Periodic Inventory Counts

Record-Keeping for Year-End Inventory and Other Tax Purposes

Forecasting

Optimizing Space Utilization

Pricing

A minimum order of inventory control tags or inventory labels can cost as little as $300 to $399. Higher-volume orders reduce the per-unit cost to as low as $0.25 to $0.50 each for an order of several thousand. Exact prices depend on the material construction, size and quantity.

Need a price list or samples? It’s easy: simply send us a request for samples.

Discover Insights for Inventory Tracking and Management

Explore our case studies, blog, buyer’s guides, specification sheets and more — and start learning more about the complex world of asset tracking. View All Resources ›

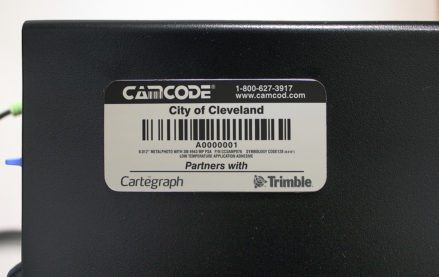

“Camcode manufactured the labels with the exact information we wanted.”

“We knew they were durable, would not fade, and would still be readable if paint got on them.”

“We expect efficiency and data accuracy to increase dramatically.”

The barcodes are eliminating mistyped numbers and speeding up the time it takes to accurately manage and track our assets.

Keep Operations Efficient with Barcode Asset Tracking Tags

If you’re having trouble finding the ideal tracking solution for your project or organization, build it with Camcode. Talk to our team today.

Frequently Asked Questions

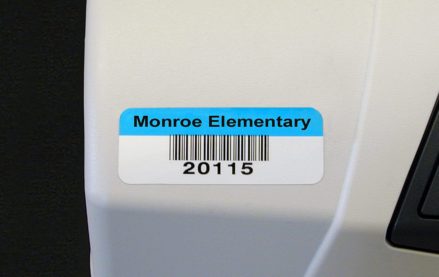

Inventory control tags are removable labels or tags that are attached directly to inventory items or their packaging. They’re not only used for tracking warehouse inventory but also for tracking replacement parts for machinery, supplies used to provide services, and other asset inventory across industries. They typically display key identifying information and data, including:

- Product name/description

- Product code/SKU

- Barcode or QR code

- Product quantity

- Location data (like aisle and bin numbers)

Inventory control tags allow employees to quickly verify product details and inventory status without having to look up information separately. They act as visual cues connected directly to the physical inventory.

Inventory control tags assign a unique identifier (UID) to each inventory item, which can then be scanned and tracked through a database system.

Inventory control tags are an essential part of inventory management. They help track stock levels, product movement, and order fulfillment within warehouse operations and other industries.

When it comes to the benefits of using inventory control tags in a warehouse and other settings, there are several key advantages:

- Accurate Inventory Tracking: The detailed product information on the tags allows for precise tracking of inventory levels, locations, and movement through scanning technologies.

- Efficient Order Fulfillment: Inventory control tags enable workers to quickly identify, pick, and verify the right products for order fulfillment, work orders, and other needs, which reduces errors.

- Stock Rotation: Tags displaying batch numbers and dates support proper stock rotation practices like first-in-first-out (FIFO).

- Space Optimization: Location data on tags is important for organized slotting and storage to maximize the use of warehouse or inventory storage space.

- Loss Prevention: Clearly labeling inventory with tags deters misplacement and helps account for all products to minimize shrinkage and loss.

- Time Savings: The data contained in inventory tags eliminates the need to look up product info separately — all the key product details are immediately visible on the tags.

- Regulatory Compliance: Inventory control tags allow tracking of lot codes, expiration dates, etc., which can aid in meeting various industry compliance requirements.

Overall, inventory control tags streamline operations, boost accuracy, and enhance productivity while enabling tighter inventory control and oversight in warehouses and other business operations.

They are an invaluable tool for modern inventory management systems.

- Barcode Tags: These are labels with a barcode that can be scanned to access product information. Common barcode symbologies include UPC, EAN, Code 39, and Code 128.

- RFID Tags: Radio-frequency identification (RFID) tags use wireless technology to transmit data when scanned, allowing for automated inventory tracking.

- QR Code Tags: These tags display a QR (quick response) code that can be scanned by smartphones or devices to quickly retrieve detailed product data.

- Paper/Tyvek Tags: Basic paper or Tyvek (synthetic paper) tags allow for the printing of barcodes, descriptions, and other information to be attached to inventory. These tags are susceptible to fading and damage from cleaning solutions, weather conditions, and exposure to moisture or liquids, which can render them unreadable.

- Fabric/Plastic Tags: More durable cloth or plastic tags can withstand moisture, tearing, and wear and tear in harsher environments.

- Color-Coded Tags: Using different colored tags can provide an easy visual system for identifying product categories, locations, or statuses at a glance.

The choice of tag type depends on factors like barcode requirements, durability needs, environmental conditions, scanning technology used, and the desired mix of efficiency, cost, and functionality for inventory control purposes.

When implementing inventory control tags, companies can face several potential challenges.

Data Accuracy:

Ensuring the information printed on the tags is complete, consistent, and error-free across the inventory is essential, but it can be difficult to maintain, especially for businesses handling a large volume of products.

Tag Durability:

In some environments and operating conditions, tags may need to be replaced frequently if they cannot withstand moisture, rips, scuffs, etc., resulting in added costs.

Integration with Systems:

Integrating inventory control tag data with warehouse management systems or inventory management applications, databases, and scanning equipment requires coordination and potentially new technology investments.

Worker Training:

Employees must be properly trained on tag procedures, such as accurately printing, attaching, scanning and replacing tags when needed. A lack of training can undermine the benefits.

Initial Cost:

Depending on the volume of inventory and tag type selected, upfront costs for implementing tags across an entire facility can be significant.

Process Adjustments:

Updating existing procedures to incorporate new tagging steps and quality control processes may disrupt employee or facility workflows initially.

Tag Visibility:

Inventory control tags may not always be easily visible based on pallet configurations or product packaging, hindering scanning.

By anticipating potential challenges like the ones listed above ahead of time, management can proactively develop strategies and solutions to help ensure a smooth and successful deployment of an inventory control tagging system.