Warehouse Signs & Signage Systems

Maximize efficiencies across your warehouse with a custom warehouse labeling system.

Build a Better Warehouse Labeling Solution

Camcode produces Custom Warehouse Signs for every application. From hanging signs, to aisle signs, to dock door signs that need to last outdoors – our warehouse sign solutions are custom designed for your application. Don’t see what you need? Our product development team is on standby to design and build your optimal sign.

Custom Signs to Streamline Your Warehouse Management Operations

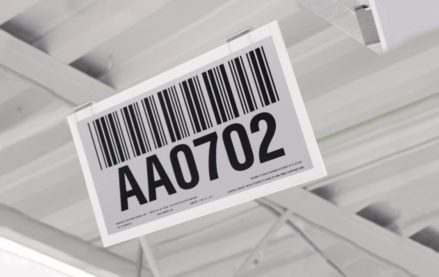

Custom warehouse signs provide a top layer of organizational efficiency that not only makes your facility look good, but enhances team productivity. Camcode’s warehouse signage options range from durable, outdoor signs for doors and docks to fixed mount warehouse signs that feature crisp bar codes for high visibility and long-distance scanning.

Get a Free Warehouse Label and Sign Evaluation Kit

Request a free warehouse label and sign sample kit today and we will send you a kit to test our durable labels and signs in your own warehouse environment.

Custom Warehouse Signage Solutions

No two warehouses are alike – and that’s why Camcode begins with an analysis of your facility’s needs and requirements to develop a completely customized solution to maximize productivity without disrupting your existing workflow. All our warehouse signs are custom-designed for your specific applications. Don’t try to mold your warehouse to fit a cookie-cutter warehouse signage solution – we’ll design customized warehouse signs in line with your needs.

A Warehouse Sign for Every Need

Save Time and Labor Costs with Consistent Warehouse Signage

Warehouse Signs Key for Supply Chain Efficiency

Color Elements Add Versatility to Warehouse Signs

Warehouse Signs with Exceptional Durability

Benefits of Custom Warehouse Signs

Each warehouse layout is unique, and facility managers must constantly find new ways to improve the efficiency of their operation based on limited space and resources. Custom warehouse signage is a popular solution for maximizing productivity and supporting optimal space utilization in these environments. Warehouse signs can be easily customized with text, graphics, and barcodes that meet the requirements of scanning hardware and match with other signs and markers in the facility. Here are some of the most important benefits of custom warehouse signage:

Increased Productivity

Optimized Space

Improved Inventory Accuracy

Safety Awareness

Common Use Cases for Custom Warehouse Signs

Custom warehouse signage has a variety of applications within the warehouse. Here are a few of the most common use cases for custom warehouse signs:

Warehouse Organization

Material Handling

Traffic Control

“We went from virtually one location to 506 locations thanks to Camcode labels.”

“We can delineate where items are stored and have better management and control by location.”

“With Camcode, I saw exactly what I was getting.”

“I got warehouse label samples from Camcode and two other companies. With Camcode, I saw exactly what I was getting. There was a nice variety of samples that helped me envision what would work best for us.”

Discover Warehouse Management Insights

Explore case studies. blog posts, buyer’s guides, specification sheets and more — and start learning more about the driving efficiencies with a warehouse labeling system. View All Resources ›

Upgrade & Evolve with a Scalable Warehouse Labeling System

Find out how a custom warehouse labeling system helps you evolve warehouse management for the digital age.

Frequently Asked Questions

When designing warehouse signs, including the most pertinent information ensures that operations run smoothly and efficiently. Here are key pieces of information that are often considered critical to include on warehouse signs:

- Aisle/Section Identification: Clear labeling of aisle numbers, section names, or other identifiers on warehouse signs is crucial for navigation and locating specific areas.

- Product Categories/Descriptions: Broad categories or descriptions of the products/materials stored in each aisle or section help workers quickly find what they need, which promotes efficiency.

- Location Codes/Coordinates: In large facilities, including location codes or coordinates on signs that correspond to the warehouse mapping system or warehouse location numbering system aids wayfinding.

- Directional Guidance: Warehouse signs should include directional arrows, icons, or text indicating traffic flow and the direction of aisle/section numbering.

- Safety Information: Signage should prominently display any relevant safety symbols, hazard warnings, or handling instructions for certain products.

- Inventory Locations: Listing the range of bin, rack, or shelf locations within each aisle or section can improve warehouse navigation and efficiency.

- Barcodes/QR Codes: Including scannable barcodes or QR codes can link signage to digital inventory information.

For durable warehouse signs that can withstand the demanding conditions of a warehouse environment, several materials are commonly used:

- Rigid PVC (Polyvinyl Chloride): Rigid PVC is the single best option due to its excellent durability, impact resistance, and moisture resistance. It can be printed on directly or used as a substrate for adhered graphics.

- Aluminum: Aluminum warehouse signs are highly durable, resistant to corrosion, and can withstand heavy use. They are ideal for both indoor and outdoor warehouse applications.

- Fiberglass-Reinforced Plastic (FRP): FRP signs are lightweight yet strong, resistant to chemicals, moisture, and temperature fluctuations, making them well-suited for harsh warehouse conditions.

- High-Density Polyethylene (HDPE): HDPE is a durable plastic material that is impact-resistant and can withstand extreme temperatures, making it suitable for various warehouse signage applications.

- Acrylic: While not as durable as some other materials, acrylic warehouse signs can offer good impact resistance and can be used in indoor warehouse environments with proper mounting and protection.

- Metalphoto®: Metalphoto® is an anodized aluminum material that offers excellent durability, tamper-evidence, and resistance to harsh conditions, making it a premium choice for security-conscious warehouse signage.

Regardless of the material chosen, warehouse signs should be designed with appropriate substrates, inks, and mounting systems to ensure long-lasting performance and readability in demanding warehouse environments.

Warehouse signs can be highly customized to meet the specific needs and branding requirements of each facility. Here are some common ways warehouse signs are customized:

- Size and Shape: Warehouse signs can be produced in custom sizes and unique shapes like circles, rectangles, arrows, or irregular forms to fit designated areas or provide directional guidance.

- Text and Graphics: The text content, including aisle numbers, product categories, location codes, and more, as well as graphics, logos, icons, and visual elements, can be fully customized.

- Color Options: A wide range of standard and custom color options are available for both the warehouse sign substrate (e.g., rigid PVC, aluminum) and the printed elements, allowing companies to incorporate branding colors.

- Printing Methods: Various printing techniques like screen printing, digital printing, or vinyl application can be used to produce crisp, durable graphics and text on warehouse signs.

- Specialty Inks: The use of specialty inks like UV inks, metallic inks, or reflective inks can enhance visibility and improve the durability of printed elements.

- Materials: While rigid plastics like PVC are common, signs can also be customized using aluminum, fiberglass-reinforced plastic (FRP), or other durable materials based on specific needs.

- Mounting Options: Warehouse signs can be customized with different mounting brackets, hardware, or adhesives to allow for wall, ceiling, rack, or floor installation as required.

- Lighting: Some warehouse signs incorporate internal LED illumination or edge lighting for increased visibility in low-light warehouse areas.

Warehouse signs, warehouse labels, and markings work together as an integrated system to provide clear organization, identification, and directional guidance throughout the facility. Each component plays a crucial role in supporting efficient operations and inventory control in warehouse management:

Warehouse Signs:

- Hanging/overhead signs display aisle numbers, product categories, and directional arrows for navigation.

- Floor markings and line striping designate travel paths, loading zones, and staging areas.

- Large wall signs identify key areas like receiving, shipping, etc.

Warehouse Labels:

- Barcode labels on products and storage such as containers, trays, and pallets enable tracking and inventory control.

- Location labels on racks/shelves indicate precise bin placement.

- Color-coded labels can denote product types, safety hazards, or statuses.

Warehouse Markings:

- Floor markings like footprints indicate pedestrian traffic flow.

- Markings on racks/shelves specify storage locations.

- Hazard markings warn of potential dangers in certain areas.

Together, this multi-layered approach provides redundancy and reinforcement of critical information. Warehouse signs provide high-visibility overview guidance, while labels and markings offer more granular product and location details at ground level. The system works cohesively — signs direct workers to the right aisles, labels identify specific inventory, and markings optimize traffic flow.