Security Labels & Tamper-Evident Bar Code Labels

Protect against theft, counterfeiting or unathorized asset transfers with durable security labels.

Improve Tracking. Minimize Risk. Anti-Counterfeit Labels Secure Your Asset Management System

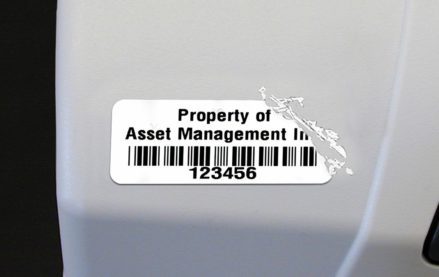

Protect against theft and counterfeiting with Camcode Security Labels. These tamper-evident labels can include custom text, and a bar code or serialized number to allow easy identification and tracking of your valuable assets. Custom security labels may be customized with your company logo or a very specific size and color.

Security Label Customizable Features

Durability

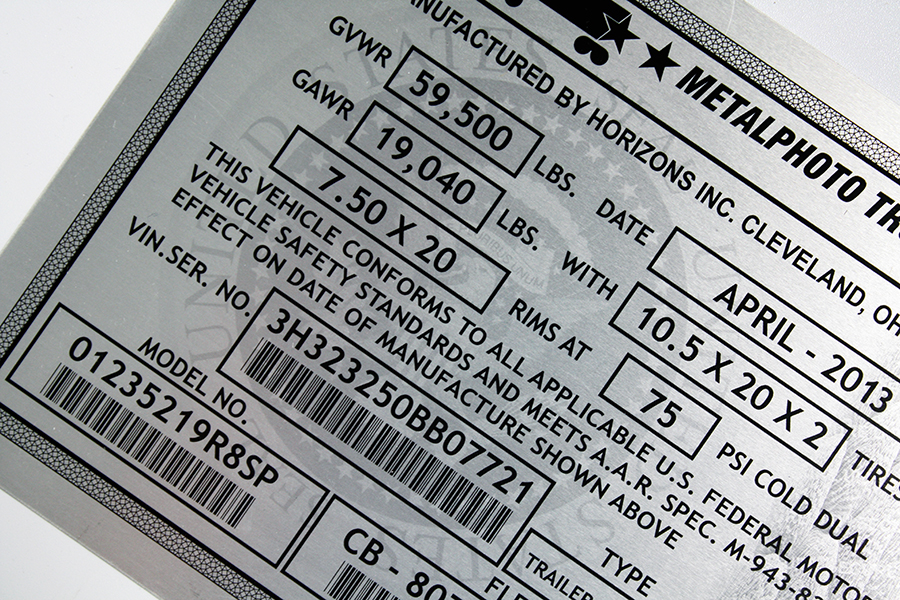

Security Labels are imaged through our Metalphoto® process, where an inorganic silver-halide image is sealed beneath the anodic layer, creating the most durable variable data label available.

Security

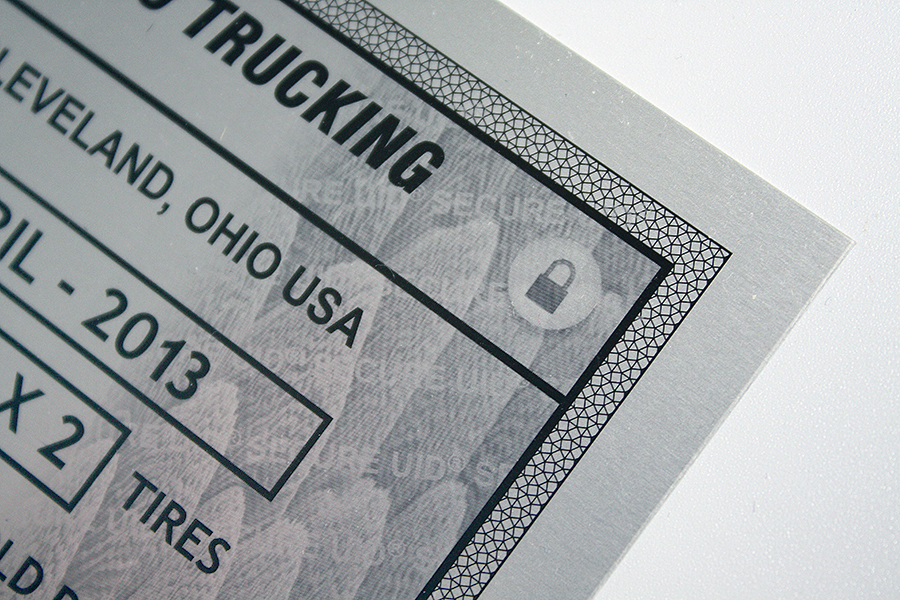

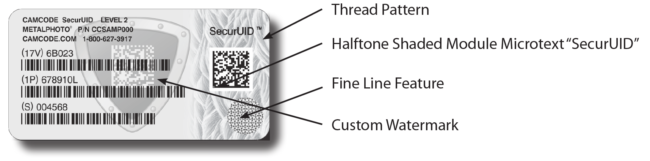

The Metalphohto process is integrally counterfeit resistant due to its proprietary sub-surface imaging technology and limited distribution network. The sub-surface, photographic resolution image produced is similar to those found in passports, identification cards and currency.

Customization

Customize your security levels based on counterfeit risk. As the levels increase, so does the assurance of authenticity. Utilizing two-dimensional (2D) bar codes or QR-codes and embedded URLs allows the use of a variety of verification options. By adding overt and covert security printing to the Metalphoto process, we create an extremely durable, item-unique anti-counterfeit label.

Anti-Counterfeit Options

What do Tamper-Evident Labels cost?

Our minimum order is $300 to $399. Higher-volume orders reduce the per-unit cost – to as low as $0.25 to $0.50 each for an order of several thousand – and exact prices depend on the material construction, size and quantity. Getting a price list and samples is easy; just ask us to request a quote.

Explore Our Most Popular Security Asset Labels

Find the most durable, custom-designed security labels and improve the management and tracking of your assets. Don’t see what you need? Our product development team is on standby to design and build your perfect label.

Benefits of Tamper-Evident Barcode Security Labels

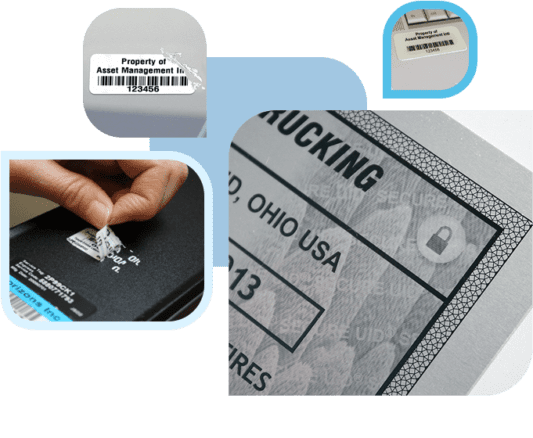

Using a barcode label with security features is a great way to increase the reliability of your asset tracking system and enhance the security of your high-value assets. These labels provide a number of important benefits for applications that require added protection. Security labels are impossible to remove without leaving clear evidence of tampering behind, discouraging theft and unauthorized transfer. Here are a few of the benefits of tamper-evident barcode security labels:

Visual Evidence of Tampering

Policy Management and Regulatory Compliance

Theft Reduction

Reliable Tracking

Common Use Cases for Barcode Security Labels

Barcode security labels are used in a number of areas where an additional level of protection is needed. They can be found in nearly any industry, and these examples of common applications illustrate the versatility of a barcode security label solution.

Manage Evidence and Sampling

Protect Valuable Property

“Their service and quality is exceptional.”

“I am extremely pleased with my decision to go with Camcode.”

“Our salesperson was very helpful in explaining how bar codes work.”

“There was a lot that I didn’t understand about the implications of bar code symbologies. Our salesperson was very helpful in explaining how bar codes work, and helped us select a different product than we had envisioned.”

Discover Insights for Security Asset Tracking

Explore our case studies, blog, buyer’s guides, specification sheets and more — and start learning more about the complex world of asset tracking. View All Resources ›

Keep Operations Efficient with Barcode Asset Tracking Tags

If you’re having trouble finding the ideal tracking solution for your project or organization, build it with Camcode. Talk to our team today.

Frequently Asked Questions

There are several features that can make barcode labels more secure and help prevent counterfeiting or tampering:

- Serialization: Each barcode label can have a unique serialized number, making it very difficult to replicate.

- Covert Features: Invisible inks, watermarks, or taggants can be embedded into the label material. These markings are only detectable when using specialized scanning equipment.

- Tamper-Evident Materials: Labels can be constructed with materials that are designed to show irreversible signs of tampering, like Metalphoto®, void pantographs, or destructible facestocks.

- Digital Signatures: 2D barcodes like QR codes allow encryption and digital signature technology to authenticate labels.

- RFID Tags: Using RFID inlays in the label allows tracking and prevents tag cloning or swapping.

- High Assurance Printing: Printing techniques such as high-resolution, micro-printing, or UV fluorescent inks make reproduction much more difficult.

- Material Sourcing: Working with accredited label suppliers and monitoring material sources helps protect against infiltration of counterfeit label stock.

Having multiple layered overt and covert security features makes it much harder to accurately reproduce or replicate barcode labels without being detected, increasing supply chain and brand security.

Unique serial numbers are typically assigned to security barcode labels through a controlled serialization process to maintain integrity and traceability. Here are some of the most common methods used to assign unique serial numbers to barcode labels.

- Central Database: A central database generates and assigns a globally unique serial number to each label printed. The database prevents duplication and can track each serial number’s status and history.

- Encrypted Algorithms: Serialization algorithms use encryption keys to create secure, non-sequential serial numbers that cannot be predicted. Complex algorithms make it extremely difficult to counterfeit valid serial numbers.

- RFID Encoding: For RFID-enabled labels, the RFID inlay chip can be encoded during manufacture with a tamper-evident unique ID that gets associated with the printed barcode serial number.

- Human-Readable + Barcode: Labels display both a human-readable serialized number and an encoded barcode version, allowing verification against each other.

- Sequential Numbering: While this method is less secure, some labels may use sequential roll or batch numbering tracked to each label run to confirm authenticity.

The single most important factor for true security is ensuring the serial number generation process is secured, audited and cannot be replicated outside authorized facilities and systems. This helps prevent counterfeiting and allows traceability.

When selecting barcode label materials for security purposes, several factors are considered:

- Tamper-Evidence Materials: like VOID pantograph facestocks, destructible vinyls, or materials that leave a permanent “scar” when removed help indicate tampering attempts. Metalphoto is a durable anodized aluminum material that is extremely tamper-evident.

- Covert Security Features: Specialty security label materials can incorporate covert features like UV fibers, taggants, or watermarks that are only visible under specific lighting conditions or authentication devices.

- Facestock Thinness: Ultra-thin facestocks make replication more difficult while ensuring proper barcode readability.

- Adhesive Aggressiveness: Aggressive adhesives that are hard to remove cleanly from surfaces further deter tampering.

- Facestock Tint: Colored/tinted materials are harder to copy accurately and can indicate counterfeits if the tint does not match approved materials.

- Material Sourcing: Using security label materials only from accredited, audited suppliers and overt material authentication measures like UV seals ensures label integrity.

- RFID Integration: Integrating RFID inlays into the security label construction provides additional authentication and traceability.

The primary objective should be to use label materials with multiple layered overt and covert security features to significantly increase the complexity of counterfeiting security labels while enabling reliable barcode scanning performance.

Standard warehouse barcode labels typically do not provide enough security features on their own. These basic labels are designed primarily for operational efficiency in inventory management rather than anti-counterfeiting.

However, there are some ways to enhance the security of standard barcode labels:

- Use of Non-Generic Label Materials: Avoiding plain paper labels in favor of more specialized label stocks that are harder to reproduce.

- Serialization: Assigning unique serial numbers to each label, tracked in a database, to validate authenticity.

- Tamper-Evident Adhesives: Using aggressive adhesives that leave residue or show damage if removed.

- Simple Overt Features: Adding basic overt security features like watermarks, UV inks, or specialized barcodes.

- Integration with Other Systems: Linking barcode data to inventory control systems and authentication processes.

However, these measures only provide basic levels of security. For true robust label security, companies need to implement layered covert and forensic security features built into specialized label materials and constructions.

This approach will significantly increase label complexity to deter counterfeiting. Standard warehouse labels simply do not have these advanced capabilities built in without customization specifically for security purposes.