Warehouse Floor Labels

A unique, and uniquely durable warehouse tracking solution.

Build a Better Warehouse Labeling Solution

Many facility managers will develop a labeling strategy while planning warehouse layouts and rack locations. There can be many high traffic areas in a warehouse, and it may be necessary to choose a number of different warehouse floor label styles to achieve optimum coverage. Our product development team is on standby to design and build your perfect warehouse floor label system.

Reach Your Goals Faster With Our Installation Services

AVOID DISRUPTING YOUR WORKFLOWS

Find the best warehouse floor label and sign material, code type, size, shape, and attachment method for your particular warehouse setup. We’ll even help with label installation, so you can start seeing improvements as soon as possible.

Get a Free Warehouse Floor Label and Sign Evaluation Kit

Request a free sample kit of warehouse floor labels and signs today and we will send you a kit to test our durable labels and signs in your own warehouse environment.

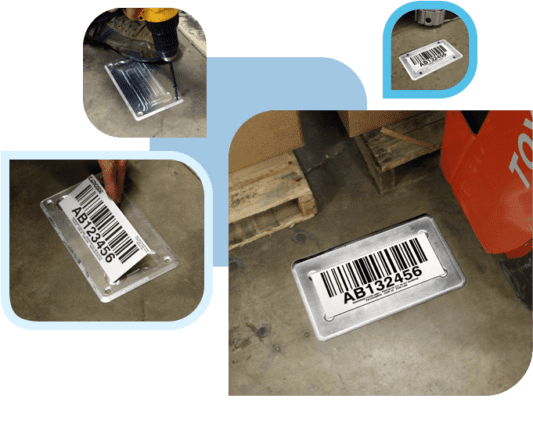

Unique Floor Label Kits for Quick and Easy Tracking

Camcode’s Warehouse Floor Labels are the most durable products you will find and easily install in less than 5 minutes per label. The ideal floor marking solution for bulk and staging locations. The 1/8″ beveled aluminum frame protects the label from abuse of pallets and vehicular traffic. Choose from our traditional screw-down or our adhesive floor label kit.

“The other vendors didn’t have an answer for our floor application and didn’t have specific industry experience. Camcode had both.”

“We selected the Metalphoto option because it gave us the durability we needed.”

“We selected the Metalphoto option because it gave us the durability we needed in an active area where freight and equipment could come in contact with the barcode. The labels also have great barcode scanner readability.”

Discover Warehouse Management Insights

Explore our case studies, blog, buyer’s guides, specification sheets and more — and start learning more about the driving efficiencies with warehouse floor labeling systems.

Upgrade & Evolve with a Scalable Warehouse Floor Labeling System

Find out how a custom warehouse floor labeling system helps you evolve warehouse management for the digital age.

Frequently Asked Questions

The specific information included on warehouse floor labels can vary depending on the type of products, industry requirements, and the organization’s warehouse management system. However, most effective floor labels typically contain the following key data points:

- Product name/description

- Product code/SKU number

- Quantity/unit count

- Lot/batch numbers

- Expiration or manufacture dates (if applicable)

- Aisle/bin/rack location

- Barcode or QR code for scanning

Clearly displaying this critical data on labels allows workers to validate products, quantities, locations, and other details at a glance. Barcodes and QR codes enable efficient scanning for inventory management activities.

Consistently labeling with these core pieces of information promotes accuracy, traceability, and operational efficiency throughout the warehouse.

Implementing best practices for labeling warehouse floors is essential for maintaining an organized, optimized and efficient operation. Here are some key best practices to consider when labeling warehouse floors and other warehouse locations.

Consistency and Standardization:

- Establish a consistent labeling system and format across the entire warehouse

- Use clear and legible font sizes, colors, and label materials

- Standardize label placement locations (e.g. on racks, bins, or floors)

Clarity and Visibility:

- Ensure labels are easily readable from a distance

- Use contrasting colors for text and background to enhance visibility

- Implement clear separators or spacing between label elements

Comprehensive Information:

- Include essential details like product name, SKU, quantity, location, and barcodes

- Consider adding expiration dates, lot numbers, or other relevant data as needed

- Utilize bulleted or numbered lists for improved scannability

Organizational Logic:

- Implement a logical numbering or labeling system for aisles, bays, and storage locations

- Group similar products or categories together for easier identification

- Align labels with your warehouse’s layout and workflow

Maintenance and Updates:

- Regularly inspect and replace damaged, faded, or outdated labels

- Invest in durable warehouse floor labels to minimize replacement needs and costs

- Establish procedures for updating labels when product information changes

- Implement a labeling schedule or system for consistent upkeep

By following these best practices, warehouses can create a well-organized and efficient labeling system that supports accurate inventory management, streamlines operations, and minimizes errors resulting from mislabeled or hard-to-read labels.

Various technologies can be integrated with warehouse floor labels to enhance efficiency, accuracy, and inventory management, which include:

Barcodes and QR Codes:

- Barcodes or QR codes on floor labels allow quick scanning for automatic identification and data capture using handheld devices or scanners. This facilitates real-time inventory updates, order picking, and tracking of product movements.

Warehouse Management Systems (WMS):

- Floor labeling can be integrated with a WMS to ensure consistency and accuracy across the facility.

- The WMS can generate and manage inventory data, such as product information, locations, and quantities.

Radio Frequency Identification (RFID):

- RFID tags can be incorporated into floor labels, enabling hands-free scanning and tracking of products and assets.

- This technology can automate inventory counts, monitor product movements, and enhance visibility throughout the supply chain.

Mobile Computing Devices:

- Warehouse workers can use mobile devices (e.g. tablets, handheld scanners) to efficiently scan floor labels for real-time data capture and updates.

- This integration enables seamless communication with the WMS and improves overall operational efficiency.

Voice-Directed Technology:

- Voice-enabled systems can provide audible instructions to workers, guiding them to specific locations based on the information on floor labels.

- This hands-free approach can enhance productivity and reduce errors during picking, putaway, and other warehouse tasks.

While there are various options available, Metalphoto® stands out as one of the best choices for several reasons:

- Metalphoto is a photosensitive anodized aluminum that provides a durable and long-lasting solution for warehouse floor labels. This material offers exceptional resistance to harsh environments, making it ideal for high-traffic areas, chemical exposure, and extreme temperatures. Unlike traditional label materials, Metalphoto® warehouse floor labels are virtually indestructible, ensuring that critical information remains legible and intact.

- Metalphoto labels offer superior visibility with options to incorporate bright colors, large text, and high-contrast designs. This feature is especially beneficial in dimly lit warehouses or areas where labels need to be easily spotted from a distance.

- Metalphoto labels are available as peel-and-stick or screw-down labels, providing flexibility in attachment options and the ability to easily replace the labels as needed.

Other materials commonly used for warehouse floor labels include:

- Vinyl Floor Labels: Durable and cost-effective, but can be susceptible to wear and fading over time.

- Heavy-duty Floor Tape: Easily applied but may peel or curl at the edges, compromising longevity.

- Paint or Epoxy Coatings: Long-lasting but require specialized application and can be challenging to update or modify.