What is Asset Identification? Methods, Asset ID Best Practices and Benefits

Asset identification is the foundation of any effective asset tracking and management system. Organizations managing diverse physical assets need asset identification to maintain accurate inventory records, streamline maintenance schedules, ensure compliance with regulations, and prevent asset loss or theft.

Proper asset identification involves assigning unique identifiers to both fixed and movable assets, which allows businesses to efficiently monitor and maintain their valuable resources. Organizations can gain full visibility into their assets by implementing robust asset identification methods, improving operational efficiency and cost-effectiveness.

Learn what asset identification is, why it’s beneficial, and the best practices to follow when implementing asset identification in your organization.

Asset identification is the process of assigning unique identifiers or labels to physical or digital assets to enable efficient tracking, management, and inventory control. Understanding the equipment and other assets you have allows you to track it.

Improperly labeled assets or duplicate labels can increase the risk of compliance issues. It also increases the chances that you’ll fall behind on preventive maintenance, and it puts your assets at risk of being lost or stolen.

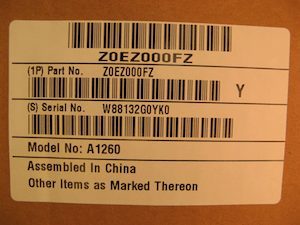

Asset tags are the most common method for asset identification. Also known as asset labels, asset tags identify a range of physical assets, including equipment, tools, racks, and machines.

All asset tags include serial numbers that serve as unique identification numbers. Asset tags can be manufactured with various materials such as foil, aluminum, premium polyester, or vinyl to suit the needs of the specific application. What matters is that organizations order asset tags made from durable materials that are strong enough to withstand the working environment.

Utilizing asset identification best practices with fixed and movable physical assets is the foundation of efficient asset tracking. Since most organizations have a diverse range of assets to track, it’s best to use a variety of different tags, such as:

The table below provides an overview of the various asset identification methods and their pros and cons.

| Asset Identification Method | Pros | Cons |

|---|---|---|

| Barcode |

|

|

| QR Code |

|

|

| RFID Tag |

|

|

| NFC |

|

|

| GPS |

|

|

The key is understanding when to use each type of asset identification tag. For example, QR codes are cost-effective and easy to implement, while RFID tags can hold more data and don’t need line-of-sight for scanning.

Regardless of the type of tag you choose, your asset tracking software will store and process data from these asset tags, allowing users to locate a specific asset quickly and easily. Some programs also include features such as maintenance schedules, warranty information, and asset maintenance history.

Asset identification is common in fields like manufacturing, but many other industries rely on this technology to reduce theft, optimize resource utilization, and streamline operations.

Hospitals and other healthcare organizations use asset ID tags to track medical equipment, manage inventory, and comply with regulatory standards. Scannable barcodes are popular for monitoring medication usage, for example.

Manufacturers use asset identification tags to track tools, machinery, and inventory. RFID tags help track equipment in real-time without direct line-of-site, helping manufacturers prevent theft and increase their chances of recovering stolen assets.

Logistics companies tag their fleet vehicles with GPS tags so they can see vehicle and shipment locations in real time. Many logistics businesses also use barcodes and QR codes in their warehouses to update customers on shipment locations and delivery status without manual data entry.

Asset identification may seem like an additional administrative burden, but its benefits greatly outweigh any extra work.

One of the primary benefits of asset identification is the significant reduction in equipment loss. Companies can easily track asset location and usage by assigning unique identifiers to each asset.

Proper asset identification methods give your company complete visibility into your assets when paired with a robust asset tracking solution. These systems provide up-to-date information on the location of your assets and record asset usage and movement.

Identifying and tracking your assets makes it easier to report their depreciation. It makes more financial sense for you to depreciate the expense of fixed assets to account for their declining value than to report the entire cost of the asset in one year. When you track each fixed asset’s depreciation status, you file more accurate business tax returns and streamline overall tax filing.

Employees spend hours every week locating and managing assets. With asset identification, they spend less time looking for items and more time on high-value tasks. For example, using barcodes and handheld scanners allows workers to quickly find items and update inventory records. There’s no need for manual data entry, allowing employees to save time while improving data accuracy.

Regular equipment maintenance is crucial for preventing breakdowns and extending asset lifespan. Asset identification systems help track asset maintenance schedules and conditions.

With asset tags and an asset tracking solution, you can note the condition of fixed assets to streamline maintenance schedules, make purchases at appropriate times, and determine the value of your business more accurately.

Many industries are required to follow stringent regulatory requirements for asset tracking. For example, healthcare providers have to provide detailed audit logs on medication usage for each patient.

With asset identification systems, employees can easily provide these audit trails and keep your organization compliant at every turn. In addition, asset identification software automatically generates audit logs when employees scan the assets.

Setting up an asset identification solution is an essential first step, but this is just a tool. Every organization should follow asset identification best practices to ensure its tagging system stays reliable and efficient over time.

If you don’t currently have an asset identification solution, it can feel overwhelming to start tagging your business’s assets. The most cost-effective option is to first identify and tag high-value and depreciating assets for tagging.

You also should identify moveable assets and those requiring regular maintenance, repairs, or replacement parts like equipment and machinery. Label IT hardware like computers and servers, audio-visual equipment like projectors, fixed assets, critical equipment like machines and tools, and furniture like desks and filing cabinets.

Another asset identification best practice is implementing an asset tracking software solution. No matter which type of asset identification your company chooses, you will benefit from eliminating manual data entry that can be rife with error.

Scanning automates processes and makes asset identification and tracking much more reliable and efficient. The Internet of Things (IoT) also improves asset tracking. This technology supports real-time asset monitoring, including location updates and automated maintenance alerts.

Always order tags made from materials rated for your working environment. For example, climate-controlled indoor facilities can get away with aluminum labels with adhesive or mechanical attachment methods that can withstand expected temperatures and humidity levels. Camcode’s Cold Storage Warehouse Rack Labels for Inventory Applications, for example, have a special adhesive designed to withstand temperatures as low as -20 degrees Fahrenheit.

Harsh outdoor environments, on the other hand, require more robust metal tags with durable printing or etching. For example, Camcode’s Rigid Metalphoto® Labels are made with photosensitive anodized aluminum and are designed to withstand the harshest environments in indoor and outdoor tracking applications. In fact, their expected lifespan is more than 20 years.

Choosing the correct tag ensures durability and readability in the long term, reducing the long-term costs of replacement.

The table below provides an overview of the common asset identification tag materials and their characteristics.

| Material Type | Durability | Compatible Environments | Pros | Cons |

|---|---|---|---|---|

| Polyester | Moderate: Resistant to scratches and moderate wear |

|

|

|

| Vinyl | Moderate: Flexible and resistant to ordinary weather conditions |

|

|

|

| Foil | High: Resistant to extreme temperatures and chemicals |

|

|

|

| Brass | High: Resistant to corrosion, saltwater, tarnish, chemicals, solvents, and extreme temperatures |

|

|

|

| Aluminum | Very High: Long-lasting and resistant to harsh environments |

|

|

|

| Stainless Steel | Extremely High: Resistant to chemicals, caustics, solvents, salt, and intermittent heat |

|

|

|

| Metalphoto® | Extremely High: Resistant to chemicals, solvents, heat, humidity, long-term weather exposure, UV, salt spray, and abrasion |

|

|

|

Asset tags transmit information to your asset tracking system. From there, it’s on your team to manage and make meaning from that data. Some asset tracking solutions include AI-powered analytics for data-driven decision-making, but not all do.

Whether you make decisions manually or with AI, you need clean data to make data-driven conclusions. Ensure all tags follow a consistent labeling format and transmit data to the system with the correct fields. It’s also good to regularly train your field crew and administrative staff on preserving data integrity.

Asset tags will degrade over time, regardless of their environment or material. Unreadable tags will hurt your data collection efforts and create blind spots in your organization. If your team notices a tag is damaged or illegible, they must report it to the office and order a replacement ASAP.

Asset identification is your first line of defense against stolen and lost assets. It also is the foundation of asset management and tracking efforts. That’s why it’s vital to choose durable labels for your assets, from Foil Asset Labels for metal, plastic, textured, and contoured surfaces, to Rigid Metalphoto® Aluminum Asset Tags that can withstand harsh environments.

Quality asset identification tags are the key to proper asset identification, but not all tags are built equally. Camcode is the most trusted name in asset ID tags, with experience manufacturing tags for use cases from chemical plants to defense. See the Camcode difference now: Request your free label and tag sample kit today.

It depends on the tags used, the complexity of the tracking software, and the scale of your operations. Barcodes and QR codes are generally the most cost-effective options, while RFID and GPS tags can be more expensive due to their advanced features.

You should also account for the costs of training staff and upgrading your IT setup. The best way to estimate the cost of asset identification is to work with a reputable vendor and assess your options.

Malicious attackers want access to sensitive asset data. It’s your responsibility to keep this data safe through practices like:

Yes. Integrating asset tracking with your ERP streamlines data exchange between these two systems, simplifying everything from procurement to finance to maintenance. Integrations improve visibility, data accuracy, and operations across departments. Plus, many asset identification platforms include pre-built integrations for popular ERPs, so you may not even need to build a custom integration.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.