What is an Asset Label? What is it Used for?

Effectively managing physical assets is essential for organizations across all industries. From expensive machinery and IT equipment to vehicles and office furniture, keeping track of these valuable assets can be challenging.

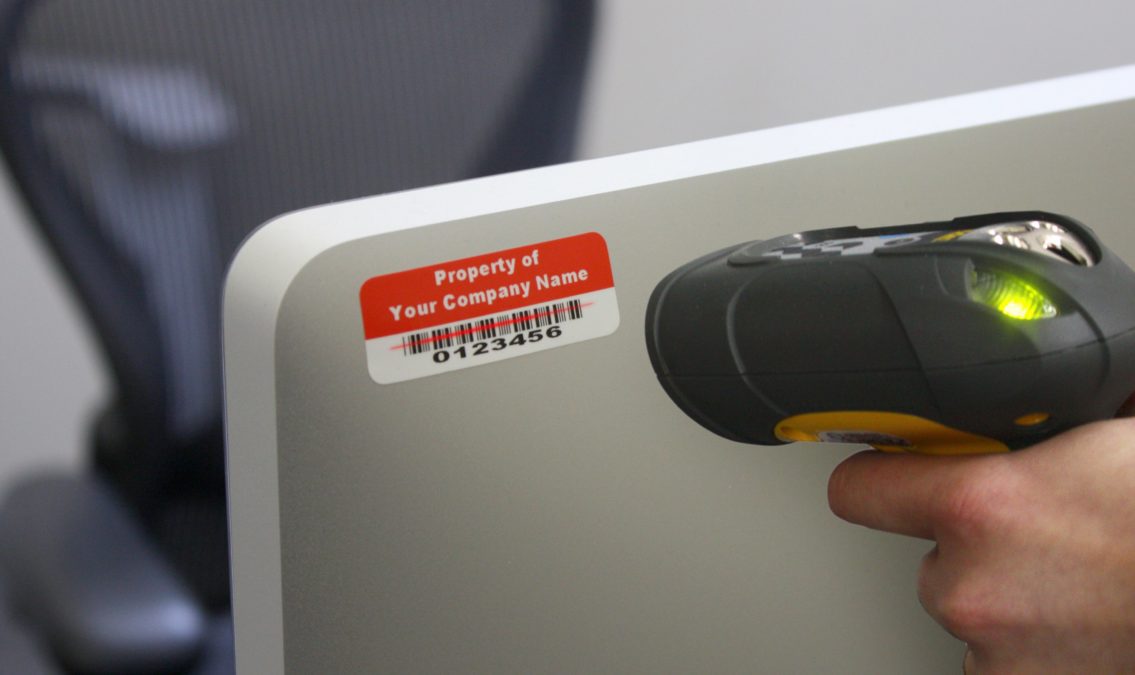

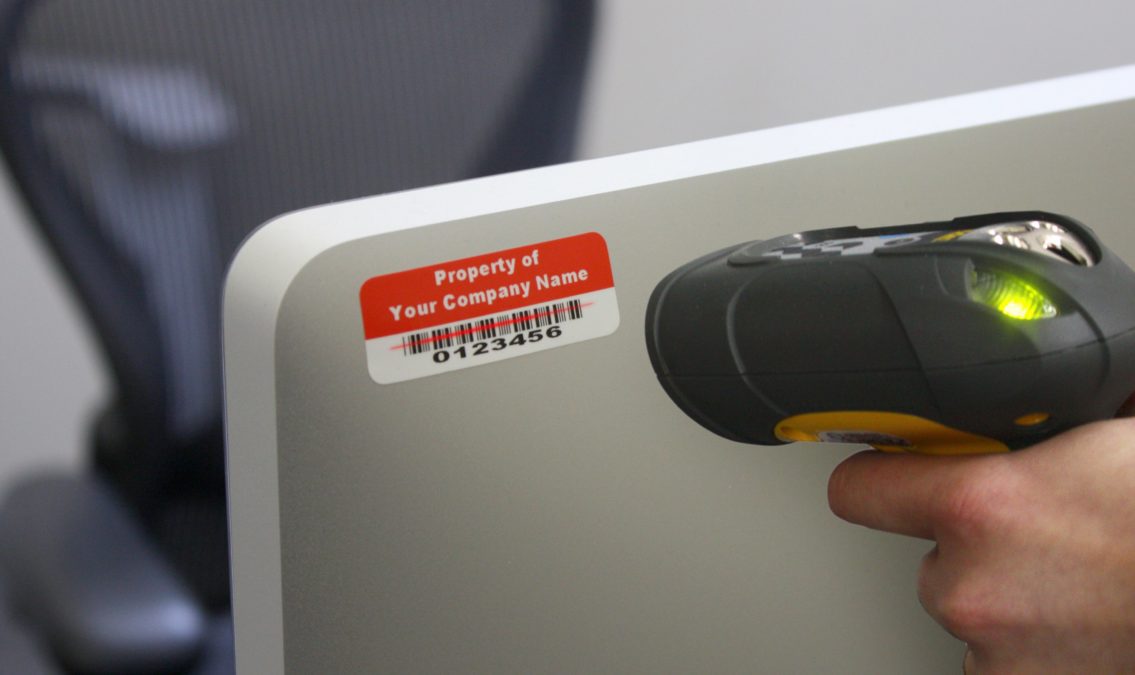

This is where asset labels come into play. An asset label is a tag or sticker affixed to a physical asset containing identifying information such as a barcode, serial number, or asset ID number.

Asset labels serve as a crucial tool for equipment tracking and asset management, allowing organizations to uniquely identify and monitor their fixed assets throughout their lifecycle. By implementing an asset labeling system, companies can gain better control over their asset inventory, streamline maintenance schedules, and optimize asset use, ultimately leading to improved operational efficiency and cost savings.

Asset labels, also referred to as asset tags, identify any number of physical assets, from equipment and tools to racks and machines. Asset tags are used to identify physical assets and feature serial numbers or barcodes for identification purposes.

Most asset labels have adhesive backing and are made of anodized aluminum, laminated polyester, vinyl, or foil. The more durable the asset label, the easier it is for the organization to conduct asset identification, tagging, and effective asset tracking.

Asset labels vary by material and size so they can best be matched to the asset on which they will be placed. The most common types of asset labels include those made of foil, anodized aluminum, polyester, or vinyl.

Premium foil asset labels are made of anodized aluminum face stock and feature a high-performance permanent pressure-sensitive adhesive. These labels are used for indoor or outdoor asset tracking and include bar code and printed information that remain readable for the lifetime of the asset.

Foil asset labels of the highest quality bond to metals and plastics as well as textured and contoured surfaces. It is a good idea to look for foil asset labels that can resist chemicals, abrasion, and solvents and that can withstand exposure to harsh environments such as those characterize by extreme temperatures.

Top-quality aluminum asset labels have outstanding durability for harsh indoor and outdoor environments. These metal asset labels may contain the company name, asset number, and barcode information and are comprised of thicker anodized aluminum face stock and a high-performance permanent pressure-sensitive adhesive or holes for attaching with rivets or screws.

As with foil asset labels, aluminum asset tags are designed to permanently bond to nearly any metal, plastic, textured, or contoured surface, and they should be designed to resist chemicals, abrasion, and solvents. Aluminum asset tags also are recommended for harsh environments.

Premium Polyester Asset Labels

Premium Polyester Asset LabelsPremium polyester asset labels are manufactured with gloss polyester face stock that is laminated with clear polyester film and a general purpose permanent pressure-sensitive adhesive. These labels identify assets with company name, asset number, and barcode and are ideal for use on high and low surface energy plastics, slightly textured, or contoured surfaces.

Premium polyester asset labels resist general purpose and household cleaners, mild acids, oil, and water and have an expected exterior life of up to two years.

If you are concerned about someone tampering with your assets, or if you want to protect against unauthorized transfer of your assets, consider tamper-evident asset labels. When someone removes these asset labels, the word “void” is left on the surface of the asset.

Top-quality tamper-evident asset labels bond to high and low surface energy plastics, stainless steel, glass, and nylon and resist general purpose and household cleaners, mild acids, oil, and water.

To discourage unauthorized asset transfers, consider using destructible vinyl asset labels. Constructed of vinyl face stock, these labels break apart when separated from the asset surface, so a person cannot remove them in one piece.

Destructible vinyl asset labels adhere to high and low surface energy plastics, textured and contoured surfaces, powder coatings, and slightly oily metals.

Removable asset labels are designed for applications that require durable short-term labels that can be removed cleanly or repositioned easily. Typically, these asset labels are used for chemical drums, shipping containers, shelves, parts, and short-term asset-tracking applications.

Proper label design is one of the most important factors to ensure your assets are easily identifiable and scannable. When it comes to best practices for label design, be sure to follow these four tips:

By optimizing label design, you can improve scanning accuracy, efficiency and asset identification across your organization.

For comprehensive asset tracking and management, it’s recommended that you implement a dedicated asset labeling software solution along with your label printing capabilities. These software systems offer robust features and capabilities, such as the following:

The core of any asset labeling system is a centralized database that stores detailed information about every asset in your organization. This includes data like asset ID, description, category, purchase date, cost, location, condition, maintenance schedules, and associated files/documents.

Asset labeling software allows you to quickly scan barcoded asset labels using mobile apps or handheld scanners. This enables real-time tracking of asset movements, locations, check-in/check-out status, and updates to maintenance records. Barcode scanning eliminates manual data entry errors.

Leading asset labeling solutions integrate bi-directionally with ERP, CMMS, accounting and other enterprise software you may already use. This integration ensures your asset data is always up-to-date and synced across all connected systems.

Track and schedule preventive maintenance based on asset usage, meter readings or predefined schedules. Record service histories, link to manuals/instructions, and get alerts for upcoming maintenance due. This extends asset lifespans.

For shared assets like laptops, vehicles or equipment, the software allows users to reserve and book assets based on their availability schedules. This optimizes asset utilization.

Generate detailed reports on asset locations, conditions, depreciation schedules, maintenance costs and more. Visualize asset data through dashboards and charts for deeper insights into asset performance and return on investment.

By leveraging a comprehensive labeling and asset tracking software system, organizations gain complete visibility and control over their fixed assets throughout the asset lifecycle. This leads to improved operational efficiencies, reduced costs through better asset utilization, and compliance with regulatory requirements.

The asset label industry is continuously evolving to meet the changing needs of organizations across various sectors. As businesses strive to optimize their asset management practices, several notable trends have emerged in the realm of asset labeling.

These trends reflect the industry’s commitment to innovation, efficiency, and adaptability, shaping the future of how assets are identified, tracked, and managed.

Let’s explore some of the key trends and developments shaping the asset labeling landscape, providing insights into the industry’s direction and the opportunities it presents for organizations seeking to enhance their asset management strategies.

Asset labels are a simple yet powerful tool for organizations to gain complete visibility and control over their fixed assets.

By implementing a robust asset labeling system, businesses can unlock numerous benefits:

The key to maximizing these benefits lies in selecting the right asset label type based on your environment and assets. From durable metal labels for harsh conditions to tamper-evident options for security, choosing the appropriate label material and design is crucial.

Moreover, integrating asset labeling with dedicated tracking software amplifies its impact. Features like barcode scanning, centralized asset databases, maintenance scheduling, and analytics provide deeper insights and tighter control over the entire asset lifecycle.

Asset labeling is the process of affixing labels or tags on a company’s physical assets like equipment, machinery, tools, etc. to assign them unique identities for tracking and management purposes. The labels typically contain information like barcodes, serial numbers, asset IDs etc. to easily identify and monitor the assets.

Essential information on asset labels includes a unique asset ID/serial number, a barcode for scanning, a brief description of the asset, and any other critical details like location, department, etc. Keep it concise but informative.

Lifespan varies by material, but quality asset labels can last 5 to 10 years or more. Polyester labels can last over 10 years outdoors. Metallic labels provide a 20+ year lifespan.

Examples of asset identification information printed on asset labels include:

This identifying information allows organizations to uniquely identify each asset in their inventory for tracking purposes when used with asset management systems and barcode scanners.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.