The Expert’s Guide to Metal Labels: Types, Benefits, Use Cases and More

Companies acquire physical assets as their business grows, and they need to manage them effectively. In order to maximize their significant investments, they need to understand where their assets are located and what condition they are in.

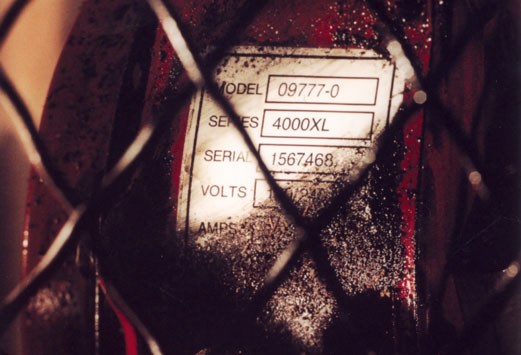

Tagging physical assets with barcode labels and asset tags, which come in all shapes, sizes, and materials, is the first step in that process. Metal labels are best for items exposed to environmental conditions that can degrade polyester or vinyl labels, but some metal substrates are better suited for certain operating conditions than others.

Understanding the different types of metal labels, identifying the use case, and knowing label tradeoffs are key to making the best choice. That’s why we’ve created this comprehensive user’s guide to all things metal labels.

When examining the options, businesses should start with label quality and application. Mother nature can be hard on devices. When assets are located or transported outdoors, the potential exposure to rain, snow, extreme temperatures, and ultraviolet light increases.

Also, sand and dirt are also common contaminants that can cause damage from abrasion, especially in coastal areas and dry climates. In some cases, the apparatus is exposed to corrosive chemicals or solvents.

Finally, sources of impact, such as other pieces of equipment or vehicles, are common in many manufacturing settings. For these applications, it’s crucial to select the materials that can withstand the expected operating conditions.

Metal labels are stronger, more durable and longer lasting than alternatives, such as plastic and paper. Metal labels provide reliability, durability, and security. In adverse conditions, a metal label is the only option. In these cases, metal labels are typically used as a permanent means of identification. Therefore, metal labels are the leading choice for meeting stringent item marking specifications and usage requirements.

In fact, it is a formal and legal requirement in some industries, such as aerospace and defense, for machinery and other assets to be properly marked with a durable metal label. Consequently, equipment manufacturers must get the design and the construction of the metal label right so that they don’t face any problems from regulatory authorities.

Suppliers offer many different types of metal labels. Their resistance tends to vary widely; therefore, labels constructed of different materials work best in different types of environments.

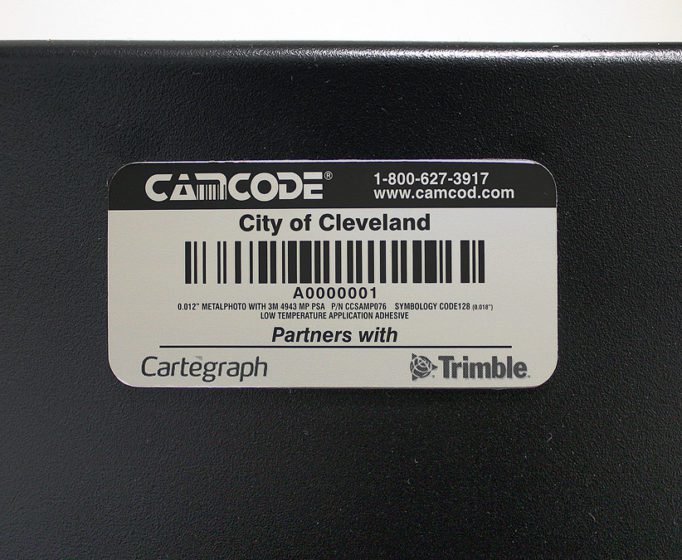

Metalphoto® Anodized Aluminum is the most durable label material available, and as such, it’s used for the most demanding industries and applications. In fact, Metalphoto has been specified by government, military, and industrial organizations for more than 50 years. In the IUID Environmental Survivability Study, conducted by the U.S. Navy’s Naval Surface Warfare Center (NSWC), Corona Division, the Metalphoto photosensitive anodized aluminum labels submitted by Camcode earned more high scores than any other material evaluated.

These labels are created using a unique manufacturing process: a silver-halide-based image is embedded within the anodic layer of the aluminum, providing the necessary durability in harsh environments. These labels survive temperatures up to 650°F, have an expected exterior lifespan of more than 20 years, and offer excellent resistance to abrasion and corrosion.

In addition, specialized extra high temperature (XHT) Metalphoto labels increase the temperature resistance to 1200°F. Standard Metalphoto labels can be purchased as a rigid or a flexible foil version or enforced with a Teflon coating for additional chemical resistance. Here’s a closer look at some different Metalphoto label options.

Foil Metaphoto Labels are 100% aluminum equipment identification tags that are quite popular. The image is sealed beneath an anodic layer of the aluminum, providing long-term durability for harsh indoor and outdoor environments. At the same time, they’re flexible (low stiffness) so they can be attached to high surface energy metals and plastics and textured and contoured surfaces using a high-performance permanent pressure-sensitive adhesive.

Foil Metalphoto Labels offer excellent resistance to chemicals, abrasion, and solvents, and they can withstand exterior exposure in the harshest environments, including extreme cold, heat, and UV. When treated with Camcode’s image intensification process, these labels have an expected exterior lifespan of more than 20 years.

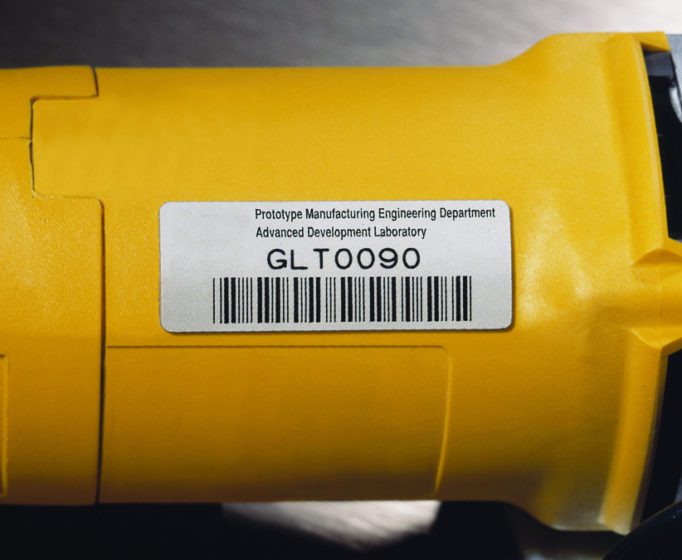

Rigid Metalphoto Aluminum Equipment Tags are durable because they are made with anodized aluminum and can be attached to surfaces with pressure-sensitive adhesive or mechanical attachment. With a variety of thicknesses for improved impact resistance and graphics sealed within an anodized layer for superior abrasion, UV, and chemical resistance, these metal equipment tags can last more than 20 years, even in harsh environments.

Teflon™ Coated Metalphoto Barcode Labels are ideal for industrial manufacturing applications requiring resistance to paint and highly caustic or acidic environments. These anodized aluminum labels are coated with Laminated or Fused Teflon that is resistant to cleaning, pickling, painting, e-coat, and powder coating processes, as well as caustics and strong acids.

Extra High Temperature Labels have an anodized aluminum face stock that’s treated with Camcode’s proprietary XHT process, enabling them to withstand exposure to temperatures up to 1200°F. This makes them ideal for the most demanding industrial high-heat applications. In addition to extreme heat, Extra High Temperature Labels offer excellent resistance to chemicals, abrasion, and solvents, and they can withstand exterior exposure to extreme cold, heat and UV.

Metalphoto isn’t the only metal label substrate material. Stainless Steel labels come in two versions: 316 and 304. Type 316 stainless steel labels are thicker with a more decorative look that can withstand punishing environmental conditions, such as exposure to salt spray in marine applications. Type 304 stainless steel labels use a ceramic-marked 304 stainless steel and also work well with any application that requires frequent cleaning with strong caustics.

Another metal label option, brass labels are often used in environments where ensuring that sparks are not struck, such as in fittings and tools used near flammable or explosive materials, is necessary. Furthermore, this material provides a clean and professional look for industrial and decorative applications. Brass possesses excellent chemical, temperature, and corrosion resistance. However, brass is a soft metal and can be prone to abrasion, but when printed with standard black graphics, these labels have excellent UV resistance and can be used in outdoor applications for long periods of time.

Corporations operate in distinct manners, collect devices in a variety of ways, and need labels for a wide range of reasons. Some common metal label types include:

Durable metal labels sometimes have a slightly higher unit cost than alternatives, but they have other advantages that make them worth the investment. In fact, metal labels can actually save your company money in several ways, starting with longer expected lifetimes. Since these labels are more durable than plastic or paper alternatives, they remain readable for a much greater time.

Maximizing the usable life of expensive assets requires ongoing monitoring, maintenance, and repair. Metal equipment ID tags save time by eliminating manual data collection practices. Efficiency also rises because there are no more input errors. These tags are designed to indicate model and lot numbers and can provide usage and safety information. They support a number of functions:

Therefore, paying a bit extra for a label that exceeds requirements is usually more efficient and cost-effective in the long run. Often, labels identify equipment that is used for several years or decades, so the added durability proves useful. Labels that meet only the minimum requirement weaken over time, need to be replaced more often (adding to your overall asset management costs) and are not as reliable.

Not all companies and applications require metal labels. The need is greatest in those markets in which equipment is exposed to the elements or harsh environmental conditions. Here are a few typical use cases:

Metal labels for equipment are the most durable labels that a company can purchase for its asset management needs. Before placing an order for new equipment identification tags, it’s important to consider some of the unique qualities of these metal tags.

Here are a couple of the most important points to keep in mind when comparing the various options.

Always compare the demands of the work environment with the specifications of each metal substrate. Most metals are durable, but some may provide unique protection against extreme temperatures, moisture, and other contaminants.

For example, Metalphoto Extra High Temperature (XHT) bar code labels are great for niche applications because they offer temperature resistance up to 1200°F and are an excellent choice for commercial ovens and equipment operating under extreme conditions.

If the equipment tag substrate is not compatible with expected environmental hazards, there is a risk of degradation and damage to the label surface.

Most metal equipment identification tags are rigid and must be attached to a flat surface using an adhesive, bolts, or another mechanical method. Some labels, such as foil equipment tags, are more flexible and can often be placed on textured or curved surfaces.

Before making a purchase, consider the attachment options for any equipment that will be tagged. This step ensures that the metal equipment tags can be securely affixed to the asset’s surface.

Corporations have invested lots of money in complex, expensive equipment. They want to maximize the usage of such devices. Metal labels are a great fit for the apparatus operating in harsh environments.

They provide needed durability and become the foundation for modern asset management solutions, allowing businesses to better track and maintain their devices.

Metal labels offer superior durability, longevity, and resistance to harsh environments compared to plastic or paper alternatives. They can withstand extreme temperatures, chemicals, UV exposure, and physical wear, making them ideal for long-term asset identification and asset tracking.

The most common metals used for labels include:

Metal labels can accommodate a wide range of information, including:

Metal labels are designed for long-term use and can last for decades when properly manufactured and applied. Their durability makes them suitable for identifying equipment that may be in service for many years.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.