What is MIL-STD-130? Specifications, Markings and Requirements for Military Standard 130

In the complex world of military logistics and supply chain management, precision and accountability are paramount. At the heart of these operations lies MIL-STD-130, a critical military standard that governs how items are identified and tracked throughout their lifecycle.

This standard, officially titled “Identification Marking of U.S. Military Property,” is more than just a set of rules—it’s a comprehensive system designed to enhance efficiency, reduce errors, and improve overall asset management for the Department of Defense (DoD).

MIL-STD-130 applies to a wide range of military property, from small components to large equipment, and impacts everyone involved in the defense supply chain, from manufacturers and suppliers to logistics personnel and end-users.

By establishing uniform methods for marking items with unique identifiers, including both human-readable information and machine-readable data, MIL-STD-130 enables seamless maintenance, accountability and tracking of military assets.

Military Standard 130 (MIL-STD-130) contains a detailed set of requirements and specifications for identification marking of U.S. military property. The standard practice involved in MIL-STD-130 has undergone some revisions, including MIL-STD-130N, which was released in December 2007 and MIL-STD-130N w/ Change 1, which was released in November 2012.

MIL-STD-130 is just one of several standards developed by the United States Government to guide individuals and organizations both within and outside of the Department of Defense (DoD) through uniform engineering and technical requirements for military-unique or modified commercial processes, procedures, practices, and methods.

As per the MIL-STD-130N w/ Change 1 Foreword, the DoD “continues to provide evolving clarification, increased insight, guidance, and marking criteria regarding implementation of machine-readable information (MRI) for identification marking of U.S. military property and automatic data capture. MRI provides a valuable tool for life-cycle asset management from acquisition through manufacture to distribution and final disposition.

However, the use of MRI may not be suitable or adequate for every identification marking need. The application of free text item identification marking in combination with or in lieu of MRI is still necessary for many end users of the identified item.”

The foreword also states, “As with product designers, simply stating that items produced under a contract shall be marked per MIL-STD-130 is not sufficient. They must clearly state what identification marking is required, to include the specific item unique identification (IUID) provisions as applicable, and that development of specific item marking requirements be based on the criteria provided in this standard.”

Other military compliance standards include requirements such as MIL-STD-129.

So, what does MIL-STD-130 mean for you? It’s important to know that there are complex item marking requirements involved in complying with MIL-STD-130, and that it can be daunting for military prime contractors and their subcontractors to understand all of them.

A particular type of marking within MIL-STD-130 is Item Unique Identification (IUID), commonly referred to as UID (unique identifier) which when specified requires all military contractors to place specific markings on their equipment. The government calls for unique and specific numbers to be assigned to government-owned and government-purchased tangible equipment, in accordance with established rules and guidelines as set forth by MIL-STD-130.

The UID compliant marking must be applied to the asset or directly marked on the asset for its lifecycle. The number associated with the UID marking is the unique item identifier, or UII, which is designed to be globally unique.

UID tags will satisfy a wide range of applications, from tactical applications with zero-reflection requirements, to applications requiring extreme sand and gravel resistance. Camcode provides mark engineering services, durable label design and manufacturing services to ensure compliance with MIL-STD-130 regulations, and offers UID registration.

Camcode is one of the few companies that also offers on-site marking installation services for hassle-free UID compliance.

MIL-STD-130 specifies several critical elements that must be included in item identification marking. Understanding these components is essential for proper implementation:

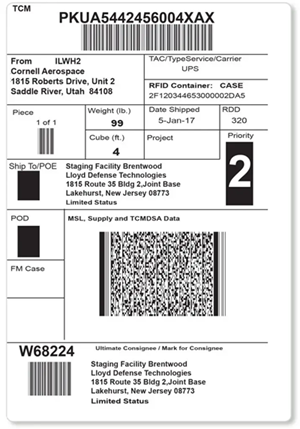

The UII is the cornerstone of MIL-STD-130 marking. It’s a globally unique and unambiguous identifier that remains constant throughout an item’s lifecycle. The UII typically consists of:

A 2D barcode is required to encode the UII and other essential information. This Data Matrix symbol must:

Alongside the Data Matrix, human-readable text must be included. This typically contains:

The standard requires that markings be permanent and durable. Acceptable methods include:

The chosen method must withstand environmental conditions and cleaning procedures without degradation.

Ensuring compliance with MIL-STD-130 is crucial for contractors and suppliers working with the Department of Defense. The standard requires rigorous verification processes to confirm the accuracy and integrity of identification markings. Here are key aspects of compliance and verification:

All UID labels and markings must undergo a verification process to ensure they meet the required standards.

This process includes:

The 2D Data Matrix barcode must meet specific quality criteria

Specialized equipment is necessary for proper verification.

Maintaining accurate records is a critical part of compliance.

To maintain ongoing compliance:

Effective data management is crucial for MIL-STD-130 compliance.

By adhering to these compliance and verification practices, contractors and suppliers can ensure their products meet the stringent requirements of MIL-STD-130, avoiding potential rejections or delays in the supply chain.

So, what does MIL-STD-130 mean for you? It’s important to know that there are complex item marking requirements involved in complying with MIL-STD-130, and that it can be daunting for military prime contractors and their subcontractors to understand all of them.

A particular type of marking within MIL-STD-130 is Item Unique Identification (IUID), commonly referred to as UID (unique identifier) which when specified requires all military contractors to place specific markings on their equipment. The government calls for unique and specific numbers to be assigned to government-owned and government-purchased tangible equipment, in accordance with established rules and guidelines as set forth by MIL-STD-130.

The UID compliant marking must be applied to the asset or directly marked on the asset for its lifecycle. The number associated with the UID marking is the unique item identifier, or UII, which is designed to be globally unique.

UID tags will satisfy a wide range of applications, from tactical applications with zero-reflection requirements, to applications requiring extreme sand and gravel resistance. Camcode provides mark engineering services, durable label design and manufacturing services to ensure compliance with MIL-STD-130 regulations, and offers UID registration.

Camcode is one of the few companies that also offers on-site marking installation services for hassle-free UID compliance.

Staying current with the latest revisions to MIL-STD-130 is crucial for contractors and suppliers working with the Department of Defense.

The most recent significant update to the standard is MIL-STD-130N w/Change 1, which was put into effect on November 16, 2012.

While this revision is not recent, it’s important to note that the DoD periodically reviews and updates its standards.

Let’s review the most recent changes to MIL-STD-130, how this might impact contractors and suppliers and some of the challenges this present.

These changes have several implications for contractors and suppliers:

While MIL-STD-130N w/Change 1 has been in effect for some time, contractors and suppliers continue to face challenges in maintaining compliance:

Contractors and suppliers working with the DoD should regularly check for updates to MIL-STD-130 and related standards. Maintaining a close relationship with DoD contracting officers and industry associations can help ensure awareness of any upcoming changes or interpretations of the standard.

To ensure successful implementation of MIL-STD-130 requirements, contractors and suppliers should follow these best practices:

Finally, because UID Labels must withstand extreme environments and last for the useful life of the asset, it is important to choose a company with durable label solutions for UID compliance.

It also is important to choose a full-service UID provider who understands the defense industry and the ins and outs of MIL-STD-130 so that your method for marking assets, managing data, installing labels and marks, and registering items meets compliance at every step of the way.

You then can be assured that you are reaping all of the benefits associated with automatic identification and data capture in relation to your UID labels.

These benefits can include property accountability, preventive maintenance management, operational cost reduction, warranty information management, logistics support, and accurate reporting. That way, UID and MIL-STD-130 compliance can add value to your business by helping you improve asset tracking of your items.

Examples of such business value include export control management (e.g., International Tracking in Arms Regulations (ITAR) requirements) and managing your asset check-in/check-out) efficiently.

MIL-STD-130 is crucial for effective asset management and supply chain operations in the Department of Defense. While compliance can be challenging, it offers significant benefits in terms of improved logistics, reduced costs, and enhanced asset visibility.

For contractors and suppliers, mastering MIL-STD-130 requirements is not just about compliance—it’s an opportunity to demonstrate quality and precision in their work. As technology evolves, staying informed and adaptable will be key to long-term success in DoD contracting.

Ultimately, proper implementation of MIL-STD-130 contributes to the overall effectiveness and readiness of the U.S. military, underlining its importance in the defense supply chain.

MIL-STD-130 marking is required for mission-critical items shipped to the DoD and all items worth $5,000 or more. It’s also required when specific contract clauses (DFARS 252.211-7003 or DFARS 252.211-7007) are included.

The minimum requirements typically include the Enterprise Identifier (usually a CAGE code), part number, and serial number. For very small parts, there may be exceptions to these requirements.

The minimum text height for DoD markings is 0.2 cm (0.08 inches), and all text should be in capital letters using a sans-serif font.

MIL-STD-130 requires a 2D Data Matrix barcode that must pass verification with at least a “B” grade. It must be permanent and durable enough to withstand environmental conditions and cleaning procedures.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.