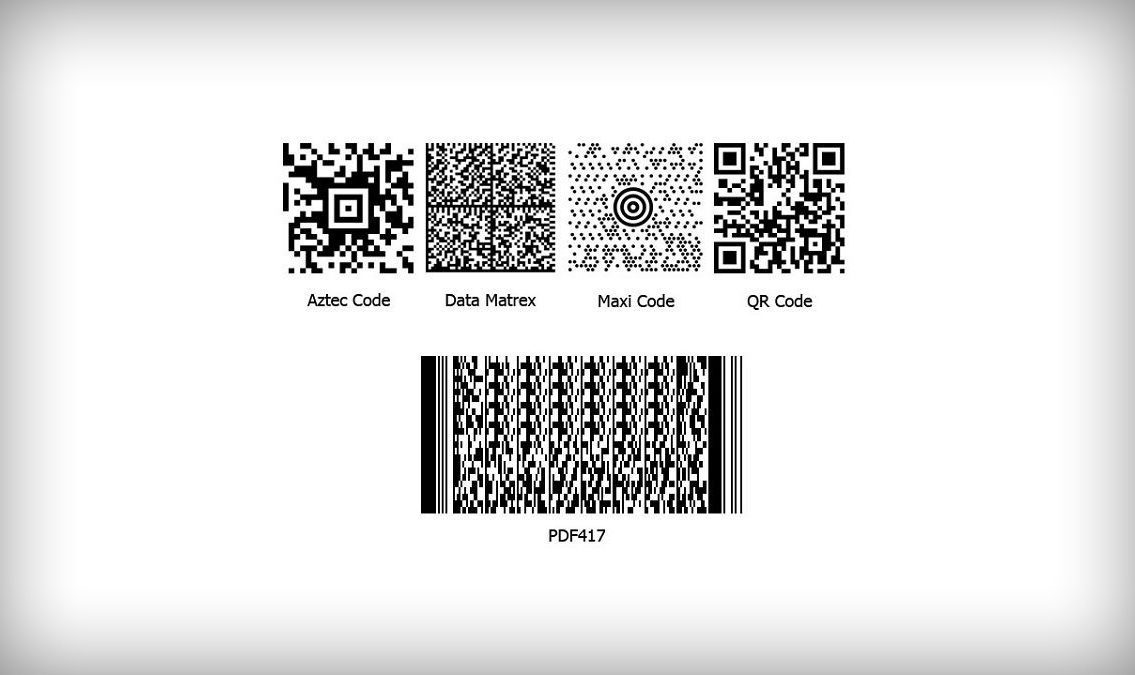

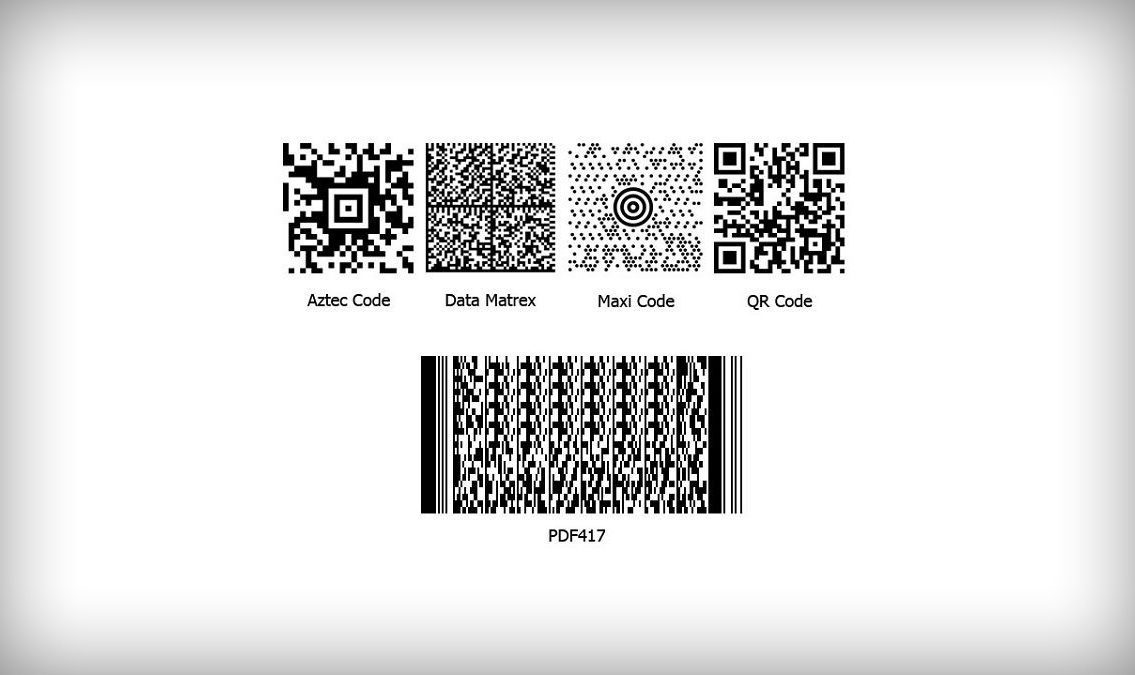

Data Matrix Code (2d Barcode) vs. QR Code

The use of quick response codes, or QR codes, is on the rise. You’ve probably seen them just about everywhere recently. But when it comes to the question of using a data matrix vs qr code, what makes QR codes different from other data matrix codes, and which code type is right for your bar code application?

A data matrix code is a two-dimensional code (i.e. 2d barcode) that consists of black and white modules, usually arranged in a square pattern. As more data is encoded in the symbol, the number of modules (rows and columns) increases. An entire Data matrix symbol can store up to 2,335 alphanumeric characters.

The alphanumeric data of data matrix codes identifies details of the component on which it is placed, including manufacturer ID, part number and a unique serial number.

The most popular application for data matrix is marking small items, due to its ability to encode a large amount of data in a small amount of space. The U.S. Department of Defense (DoD) mandates the use of data matrix codes for Unique Item Identification (UID) of certain assets such as weapons and critical components of major systems.

These assets must be permanently marked with a unique data matrix code in accordance with Military Standard 130. Much of the Aerospace Industry, especially members of the Air Transport Association (ATA), aims to have all components of every new aircraft identified by data matrix codes.

A QR code is another type of 2D code that consists of black modules arranged in a square pattern on a white background. The information encoded can be made up of any kind of data such as binary or alphanumeric.

First designed for the automotive industry to track vehicles during the manufacturing process, QR codes have more recently become popular for more commercial uses such as entertainment and marketing that targets mobile phone users. QR codes storing web addresses appear in magazines, on signs, etc.

Users with a bar code scanner application on their phone scan the image of the QR code to display text, contact information, or open a web page in the phone’s browser.

Although they are not typically used in traditional data capture applications, QR codes can be useful when software programs are not available through a scanner, but can be reached through a website. By scanning the QR code, the data is then transferred to the site where it is entered.

For asset tracking, asset identification and data-driven applications, traditional data matrix codes are generally the best choice. Though usually small in size, the data matrix code can store large amounts of data for encoding, making them appropriate for a wide variety of applications.

But there are more advantages to using a data matrix vs QR code. Here are 6 of the most important reasons.

1. High Data Capacity in a Small Space:

Data matrix codes can store a significant amount of data in a relatively small area. They can encode up to 2,335 alphanumeric characters, making them highly efficient for applications where space is limited. This high data density is particularly useful for marking small items and components, which is why they are preferred in industries like aerospace and defense.

2. Robust Error Correction:

Data matrix codes have strong error correction capabilities, which means they can still be read accurately even if they are partially damaged or obscured. This is crucial for environments where labels might be exposed to harsh conditions, such as manufacturing or outdoor settings. The error correction ensures that the data remains accessible and reliable over time.

3. Industry Standards and Compliance:

The U.S. Department of Defense mandates the use of data matrix codes for Unique Item Identification (UID) of certain assets, including weapons and critical components of major systems, in accordance with Military Standard 130. This standardization ensures consistency and reliability in asset tracking and identification.

Similarly, the aerospace industry, particularly members of the Air Transport Association (ATA), aims to have all components of every new aircraft identified by data matrix codes. This widespread adoption in critical industries underscores the reliability and effectiveness of data matrix codes.

4. Versatility and Adaptability:

Data matrix codes are versatile and can be used for a wide range of applications beyond just asset tracking. They can encode various types of information, including manufacturer IDs, part numbers, and unique serial numbers. This flexibility makes them suitable for diverse applications across different industries.

5. Durability and Longevity:

When used with durable asset tags, data matrix codes can withstand harsh environmental conditions, including exposure to chemicals, abrasion, and extreme temperatures. This durability ensures that the codes remain legible and functional throughout the lifecycle of the asset, reducing the need for frequent replacements or re-marking.

6. Enhanced Security:

Data matrix codes can incorporate additional security features, such as encryption and authentication, to protect sensitive information. This is particularly important for industries dealing with confidential or proprietary data, ensuring that the information encoded in the Data Matrix Code is secure from unauthorized access.

In summary, data matrix codes offer several advantages over QR Codes for asset tracking, identification, and data-driven applications. Their high data capacity, robust error correction, compliance with industry standards, versatility, durability, and enhanced security make them the preferred choice for many critical applications.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.