What is IUID? The Basics of the DoD’s Item Unique Identification Program

With resources dispersed around the globe, asset management is an essential function for the military and defense industry. In addition to large assets like planes, weapons, and heavy equipment, organizations must also organize and stock smaller instruments and parts.

However, it’s easy to lose important assets without proper tracking. It soon became apparent that organizations needed a unified way to monitor high-value equipment and items, especially those that could be dangerous in the wrong hands.

The U.S. Department of Defense (DoD) created the Item Unique Identification (IUID) program in 2004 as a means to create a reliable tracking system for important assets. With IUID, every item receives a unique code, known as a Unique Identifier (UID), imprinted on a tag or a label.

Employees scan these codes to store the item’s associated data in a centralized database. This system allows personnel to access records, perform maintenance, and transfer assets without any confusion about a specific item’s location or usage history.

However, because of the system’s complexity, there are some misconceptions about how organizations manage IUID and what the requirements are for any vendor or supplier that works with the U.S. government, as well as those that manufacture parts or supplies used by government entities. In this guide, we’ll give you an overview of basic IUID principles, what the marking requirements are, and how to use the IUID registry.

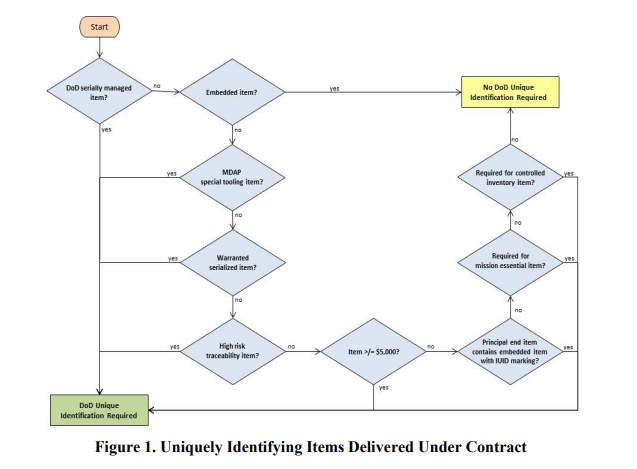

Screenshot from Department of Defense Guide to Uniquely Identifying Items

IUID is the DoD system that uses unique identifiers to distinguish items from others like it. The terms UID and IUID are used interchangeably.

With this organizational system, every item receives a unique identifier (UI) or a Unique Item Identifier (UII) comprised of both numbers and characters. Every unique identifier refers to a single piece of hardware or a unit formed by a grouping of components or parts. Put simply, all items with a cost over $5,000 or with a special designation must have a UI.

IUID has stringent requirements that can be difficult to understand. A few of the most important UIUD reference materials have been compiled by the U.S. Navy, including:

As a partner organization, you don’t need to worry about memorizing all aspects of IUID regulations. MIL-STD-130 contains the majority of specification and marking requirements for IUID labels. MIL-STD-129 also contains additional barcode requirements. These documents will give you a good overview of how the various program components intersect.

While the U.S. Department of Defense created IUID standards, the system also aligns with international standards. This compatibility plays a crucial role in the adoption of IUID, making it scalable, easier to track, and simpler to integrate into various systems. By aligning with these international standards, IUID improves traceability and prevents counterfeits in the global supply chain.

IUID is rooted in the principles of ISO/IEC 15459 standards for unique identifiers, which ensure global interoperability. Since IUID ensures globally unique and universally recognizable identifiers, it can easily integrate into any system that follows ISO standards. Not all industries use ISO, but this approach supports consistent identification across borders, improving traceability.

IUID also follows the data matrix barcode standard ISO/IEC 16022. This barcode standard makes IDs machine-readable, significantly speeding up data processing and updates. It’s also universally accepted in manufacturing, logistics, and retail.

ISO/IEC standards are helpful for identifiers, but there are also standards for defense supply chains. That’s why IUID also complies with NATO standards like STANAG 2290, which streamlines tracking across all NATO allied nations.

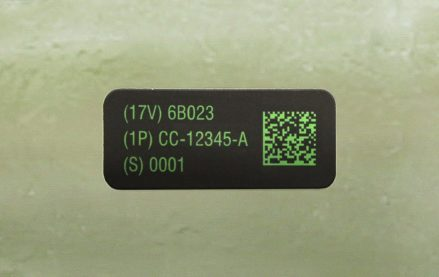

An IUID number, or code, comprises an alphanumeric series of characters. It’s always accompanied by a 2D data matrix barcode when applied to an item. There are three ways organizations can create IUID numbers:

The IUID Registry is a centralized database of all IUID information housed within the military’s Wide Area Workflow (WAWF) e-Business suite. Government employees and contractors can apply for a Common Access Card (CAC) to access the system. Useful data provided for each item includes the UII, initial value, chain of custody, and an explanation of how it is currently marked.

The IUID program is an important consideration for any defense contractors working in the industry. Knowing about this system can add value to an organization beyond simply ensuring compliance.

This robust system implements standard requirements to ensure high-quality IUID labels that can reliably track assets anywhere.

Screenshot from Department of Defense Guide to Uniquely Identifying Items

IUID marking requirements change frequently, so it’s necessary to consult the most recent standards for up-to-date guidance. The basic parameters require:

In addition to these details, when designing a proper IUID mark, you should also try to protect it, minimize attachment failures, and ensure adequate production quality. That’s why choosing durable UID-compliant labels is crucial.

Some IUID marking requirements specify the marking method you must use for the asset. Whether it’s a requirement or you’re simply trying to pick the best marking method for each item, there are plenty of ways to place an IUID on an item.

Adhesive foil labels are ideal for items with a smooth surface. These pre-printed or laser-etched labels have a strong adhesive that bonds to the item’s surface with little effort.

Adhesive foil is easy to apply and replace and is compatible with many materials. However, it’s less durable than direct marking methods, like a laser, and tends to degrade over time or with exposure to extreme conditions.

Many organizations prefer laser marking for defense purposes because it’s fast, accurate, and permanent. With this marking method, a laser engraves the IUID barcode directly onto the item’s surface.

It’s highly durable and works great on metal, ceramics, and even some plastics. However, laser marking does require specialized equipment, and it isn’t a fit for delicate materials that warp under heat.

Like laser marking, shot peening marks the surface of an item for permanent labeling. While it isn’t as precise or professional-looking as laser marking, shot peening uses small glass or metal beads to create indentation-based marks.

It’s durable and doesn’t require special equipment. However, you’re limited to only metal substrates, and the marking quality can vary.

Thermal spray marking applies a layer of material to the item that you mark with the IUID. It sprays molten material onto the surface to create an incredibly durable coating, adding a protective layer over the IUID.

Thermal spray is very complicated and requires expensive equipment. Because it uses intense heat to label items, it’s typically reserved for heavy-duty industrial applications.

Physically marking items with IUIDs is helpful, but some organizations are moving away from them altogether. Virtual IUIDs have been around for more than a decade, but they’re becoming more widely used in the evolution of traceability.

Most items are still good candidates for physical marking. Virtual IUIDs are ideal for products where traditional physical markings are impractical.

A virtual IUID exists solely in digital form. This global identifier tracks items without physical markings. Instead, your team stores and manages the identifier digitally, still logging uniquely identifiable data in your system for that item.

Virtual IUIDs require intensive employee training and aren’t a fit for all situations. However, they’re helpful for:

Virtual IUIDs are a great option, but they come with the challenge of maintaining data integrity. Always record and track virtual IUIDs in your asset management solution to ensure consistency. Training employees on updating and verifying records for virtual IUIDs is also essential to ensure accuracy.

Photo by Don Jackson-Wyatt from Unsplash

Following IUID regulations is essential. However, these regulations give organizations some leeway in how they implement IUIDs. A well-implemented IUID system can dramatically improve asset tracking, lifecycle management, and operational efficiency. Follow these best practices to create a strong IUID tracking system.

Before you start implementing IUID, outline what you hope to get out of this new system. Your goal might be improved traceability, cost savings, or compliance. At this stage, decide which items require IUIDs and which don’t.

Now that you know which items need IUIDs, you can choose an appropriate marking method based on each item’s material. While the marking method needs to fit the item, it must also work with your organization’s budget and equipment.

If you choose a less durable option like adhesive foil labels, understand that they will need more frequent maintenance and replacements than other options. You may even need to set reminders for your maintenance team to remove items out of circulation when their labels are damaged or illegible.

Always use standardized formats for IUID. Follow ISO/IEC 15459 and MIL-STD-130 guidelines for data structure and encoding. Use barcodes to capture and store comprehensive details about each item, including the acquisition date, location, and maintenance history. Periodically review the accuracy of item data and identifiers to keep your data clean.

If you’re a federal contractor, you must follow all IUID requirements. However, it can be challenging to follow this complex web of standards. While this isn’t a comprehensive list, ensure your organization’s IUID processes follow these guidelines:

While they may seem overwhelming at first, IUID’s numerous standards and regulations make end-to-end traceability possible—no matter where in the world an asset is located.

Implementing and maintaining an IUID system requires a clear understanding of its requirements, as well as following best practices to maximize the value of these labels. Tailor your approach to suit your unique needs while adhering to DoD standards.

Integrating IUID might seem like just a checkbox for compliance, but it’s an opportunity to streamline operations and preserve your most important assets. Adopt the right tools to unlock the full potential of IUID with Camcode.

Our software-compatible IUID labels are durable, 100% customizable, and comply with MIL-STD-130 and other government, industrial, and defense standards. Get free label samples to see the Camcode difference firsthand.

No, only specific items require IUID. If your items meet any of these requirements, you must mark them with an IUID:

It depends on the violation, but failing to meet IUID standards is a big deal. It could result in:

Yes, as long as they meet specific requirements. You can integrate serial numbers or batch numbers into IUID and some commercial codes, like vehicle identification numbers (VIN).

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.