6 Key Benefits of Automated Inspection

Automation is a technology that is driving innovation, efficiency, and performance at every level and in every industry. Has it changed the world? Absolutely – thanks to the ability to offshore tasks to robots and computers, more human capital is now available to work on bigger projects and more complex work.

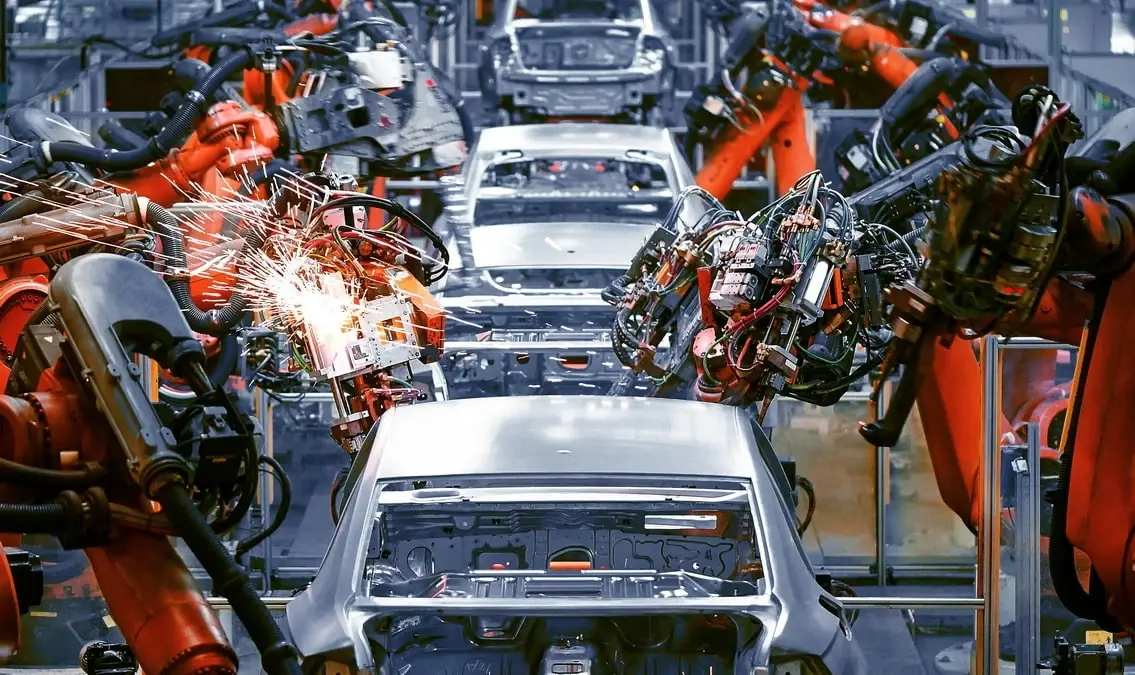

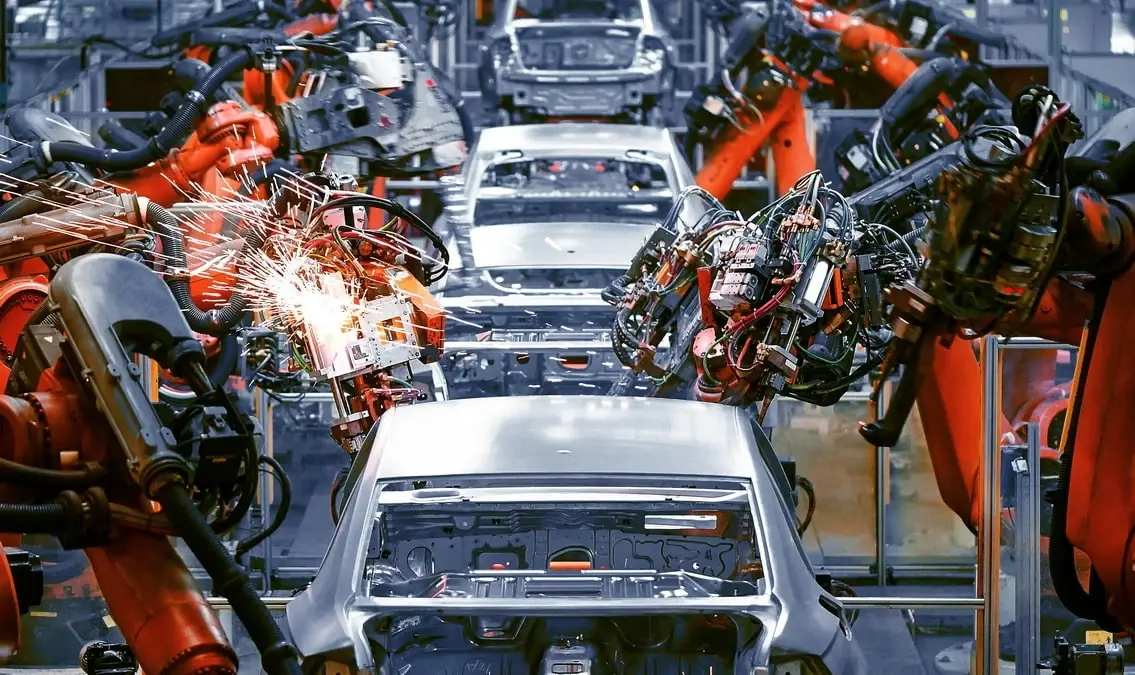

That’s certainly the case in manufacturing, and automation has transformed assembly lines, warehousing operations, facility and asset inspections, and countless other elements of the industrial ecosystem.

Automated inspections, or the use of technology to assess and inspect processes or assets without the direct involvement of a human operator, are a powerful tool when deployed effectively. But just how beneficial can automation be in this regard?

Check out the six benefits we’ve compiled below. This list – far from exhaustive – is a taste of what you can expect when you begin automating your inspection processes:

There’s no doubt about it: automation saves countless man hours. Compared to manual inspections, the tools used to automate inspection processes can perform quality control checks on production, or verify the condition of equipment in a fraction of the time.

Today’s array of cameras, computer programs, and sensors can work together to review, document, process, and flag data in seconds; tasks that once would have required the time and focus of one or even several individuals.

That employee time can now be reallocated toward more production or strategic work, serving a double benefit of keeping employees happier while driving operational efficiency.

Inspection processes in a modern plant aren’t just limited to finished goods. Your facility’s assets, equipment, and processes can also be better monitored and reviewed more completely than ever, thanks to the complementary relationship of today’s automation and maintenance technologies.

Predictive maintenance, a service strategy that’s one of the hottest topics in industrial servicing circles, is especially reliant on continuous, automated monitoring tools. With automation, you can collect data about almost any metric as it relates to an asset’s condition, allowing you to stay ahead of any potential failures or breakdowns that could bottleneck operations.

Setting up monitoring and alerts like this ultimately enhance transparency into your operations – critical for finding additional cost drivers or inefficiencies and addressing them appropriately.

Inspection is a critical but repetitive process, and human QC inspectors, succumbing to the slog of the workday, are liable to occasionally let things slip through that maybe should have been rejected. Computers, however, don’t tire, lose focus, or get bored. They bring unwavering adherence to the job at hand, making them perfect for inspection work.

The objective nature of quality control – with its defined parameters of what’s acceptable and what isn’t – allows these advanced machines to hold everything that passes through their purview to the same exact standard.

For customers, this means that what they purchased is much more likely to perform as expected; for businesses, this can help drive down product returns and improve their brand’s reputation. Should there be a spike in rejects, the data can help your team isolate the trend, find what’s driving it, and develop a solution.

The benefits of this are clear: higher-quality products leave your facility, production problems are quickly flagged and addressed, and your internal operations and external image improves.

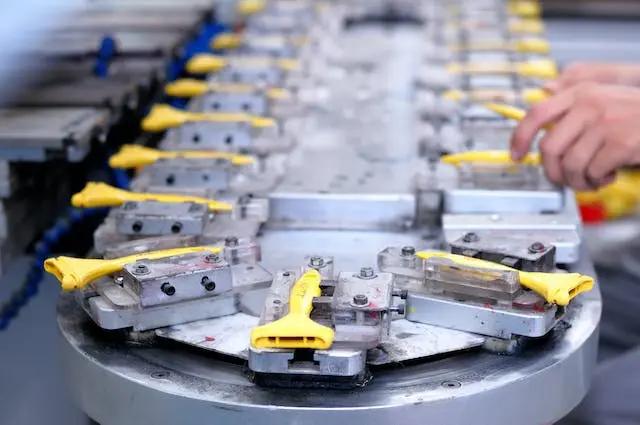

Automating the inspection process also allows manufacturers to analyze countless data points of the asset being inspected – data that can be processed incredibly fast thanks to modern computing. In the same amount of time a human operator might need to identify visual fit and finish flaws, a set of sensors may have already captured and processed literally millions of data points.

The technology behind this is known as automated optical inspection, or AOI. It enables visual analysis of an asset that’s far more in-depth than can be accomplished with the human eye. When these or other automated inspection strategies are implemented, manufacturers get better results without sacrificing speed or efficiency on the assembly line.

Check out the video below to learn more about automated optical inspection.

If you’re upgrading tooling for a new product iteration, adding a completely new product line, or just making small running changes to what you’re currently producing, automated inspection technology is quick to adapt – just program the hardware and software with the latest parameters defining what’s acceptable and what’s not. You’ll soon be humming along, with your automated tools already up to speed.

That’s a marked contrast to training human QC inspectors, who will need more time to reliably identify what does and does not pass muster as your new or updated products begin coming down the assembly line. Automated tools can help you mitigate the teething issues that come with working through such a switch, a boon to plant management and staff alike.

The financial benefits of automated inspections can be felt across an organization, from the manufacturing floor to the offices of the customer service and returns departments.

In the plant or factory, many of the cost efficiencies can be traced back to labor: automation means fewer human operators are needed at QC stations, allowing you to reassign those associates to higher-value work.

Many employees will likely be happy about the responsibility change, which can help bolster morale and drive down turnover. It’s also an opportunity to realize a higher ROI on staffing investments – in other words, the chance to do more work with the same-sized team.

In the back end of the business, the more robust inspections made possible by automation will help weed out production units that aren’t up to your firm’s standards – before they have a chance to end up in a customer’s hands.

This can reduce return volumes and all the costs associated with taking back faulty products; it can also help bolster your reputation for manufacturing quality products, a surefire way to build brand value.

If there’s one silver bullet in this industry that can save you money, drive improvements in quality control, and improve overall operational efficiencies, it’s automation. Whether you use it to inspect the products that bear your brand name or to augment the safety and compliance audits required by regulatory bodies, automated inspection technology is an incredibly powerful, versatile tool that deserves a closer look.

It’s already considered indispensable when it comes to manufacturing high-tech goods like microchips and TVs – and it may turn out to be equally crucial to your own operations.

Automated inspections enhance quality control by employing advanced sensors and computer vision technologies to detect defects with precision and speed. This ensures consistent product quality, reduces human error, and enhances overall production efficiency.

Artificial intelligence powers automated inspections by analyzing vast amounts of data from sensors, cameras, and other sources. This enables the system to learn and adapt, identifying defects, anomalies, and trends, ultimately optimizing inspection processes and contributing to continuous improvement.

Yes, automated inspection systems are highly customizable. Manufacturers can tailor inspection parameters, criteria, and tolerances to meet specific product standards and industry regulations. This flexibility ensures that automated inspections align with diverse manufacturing needs, fostering adaptability and scalability across various production environments.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.