RFID Asset Tracking: How Does Asset Tracking with RFID Work?

Tracking assets is an important part of running an efficient, streamlined business, especially if your organization has a lot of inventory, equipment, tools, or machines. In the past, tracking assets involved manual documentation and inventory checks, which was a time-consuming and error-prone process.

Fortunately, modern asset tracking is much easier thanks to technologies such as durable barcode labels and radio frequency identification (RFID).

Asset tracking with RFID enables businesses to track assets in real-time and reduce errors while saving time and effort. RFID asset tracking can certainly improve your business, but some organizations are hesitant to embrace new ways of tracking assets. Learn how the asset tracking process works with RFID and why RFID is a solid choice for modern asset tracking.

Radio-frequency identification (RFID) tags originated around the end of the Second World War. However, the history of RFID development is complicated, and no single person is considered to have invented the technology.

RFID tags fall into either active or passive categories. Active RFID tags use a small battery for power, while passive RFID tags use the radio energy itself, both for power and communication.

There are three categories of RFID tags that can be either active or passive:

LF tags are typically used to track livestock or to open gates and doors. They must be in very close proximity to the reader to function.

HF tags are used for things like tickets, payments, and moderate amounts of data transfer, but they suffer a slight sensitivity to radio interference.

Finally, UHF tags can work from up to around 15 feet away. The downside is that they are extremely sensitive to interference.

Traditionally, you would tag assets with barcodes or QR codes to scan them into an asset tracking system. RFID tags work similarly, but they remove the need to scan information manually, which can help you save a lot of time.

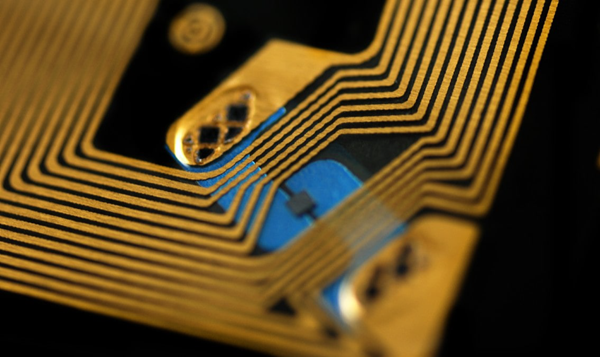

When you perform asset tracking with RFID (or perform inventory management with RFID), you attach an RFID tag to an object. The tag contains a microchip and an antenna, which uses radio waves to communicate with a reader.

The reader sends out a radio signal that activates the tag, and the tag responds by sending back a unique ID number. This ID number is used to identify the asset and automatically track its movements.

Asset tracking might sound complex, but it’s actually much more convenient than a traditional check-in/check-out asset tracking system. Just follow these steps to implement asset tracking with RFID labels:

Spreadsheets make it difficult to manage your inventory and assets accurately. If you’re trying to improve the asset management process, RFID labels are a solid choice that comes with many benefits, including:

However, keep in mind that RFID isn’t the best tracking technology for every application. In some cases, durable barcode labels are a more suitable choice. For military asset tracking, for example, durable unique identification (UID) labels are a better choice, particularly for meeting MIL-STD-130 and MIL-STD-129 specifications.

Asset tracking with RFID technology is a game-changer for businesses looking to streamline their operations and reduce errors. With an RFID system, businesses can track assets in real-time, reduce errors, increase efficiency, improve security, and scale their operations.

As RFID technology continues to revolutionize the asset tracking industry, businesses need the right tools to streamline their operations. Whether you need to track inventory in a warehouse or monitor equipment on a job site, Camcode’s RFID labels and durable barcode label solutions can help you achieve real-time tracking, increased efficiency, and improved accuracy.

Don’t miss out on the benefits of RFID technology: upgrade your asset tracking system with Camcode’s RFID labels.

RFID technology is widely used in various industries for asset management, including:

When it comes to using RFID technology for asset tracking, there are some concerns.

RFID technology can suffer from interference. The idea was always to enable a reader to scan a subset of assets or inventory, read every RFID tag in that zone, get a perfect count, and move on.

Unfortunately for RFID technology, not every tag responds when it is instructed to do so. These failures often stem from proximity issues or radio interference.

Additionally, not all RFID tags are created equal. Several enterprise-level companies have created proprietary RFID systems, which means they don’t always work well together.

If one company finds a great way to track and control its assets with RFID, that same method should be simple and clear enough to work for everyone. Unfortunately, that’s not the case.

The problem is that a consensus for protocols has not been established. Those who encounter any limitations with RFID technology should be in search of an alternative method for tracking assets.

Yes, RFID tags can be used for surfaces that are not flat. There are specialized RFID tags designed to work on curved or irregular surfaces, such as cylindrical containers or assets with complex shapes

Yes, dual frequency RFID labels can work with metal assets, although their performance may be affected by the metal’s presence. Specialized “on-metal” RFID tags are designed to have a stronger signal and better withstand interference caused by metal surfaces

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer to plan a successful asset tagging project for any maintenance tracking or facility management system.