The Ultimate Guide to RFID Systems

Pet microchips, E-ZPass toll scanners, and industrial shipments all have one thing in common — they all utilize RFID technology. RFID can automatically communicate critical information about assets, and businesses rely on RFID systems to accurately track assets, prevent loss or theft, and improve business processes.

RFID is a popular solution that’s gaining traction in multiple industries. If you want to introduce RFID to your business, it’s good to understand how this technology works and what it can do for your organization.

In this guide, we’ll cover what RFID is, how RFID systems work, its pros and cons, examples of RFID in today’s world, and how to implement an RFID solution for your business.

Radio Frequency Identification (RFID) is a wireless communication system that belongs to a larger group of technologies called Automatic Identification and Data Capture or Automatic Identification and Data Collection (AIDC). All AIDC technologies automatically identify, collect, record, store, and communicate information with minimal human intervention.

RFID technology transmits digital data through radio waves. This makes it possible to automatically identify and track objects without the need for physical contact or direct line-of-sight. Businesses use RFID systems for supply chain management, inventory tracking, asset tracking with RFID, access control, and much more.

RFID technology is in no danger of becoming obsolete anytime soon, either. With the global market worth $8.9 billion in 2020, it’s predicted to reach $13.6 billion by 2025 and $20.2 billion just another five years later.

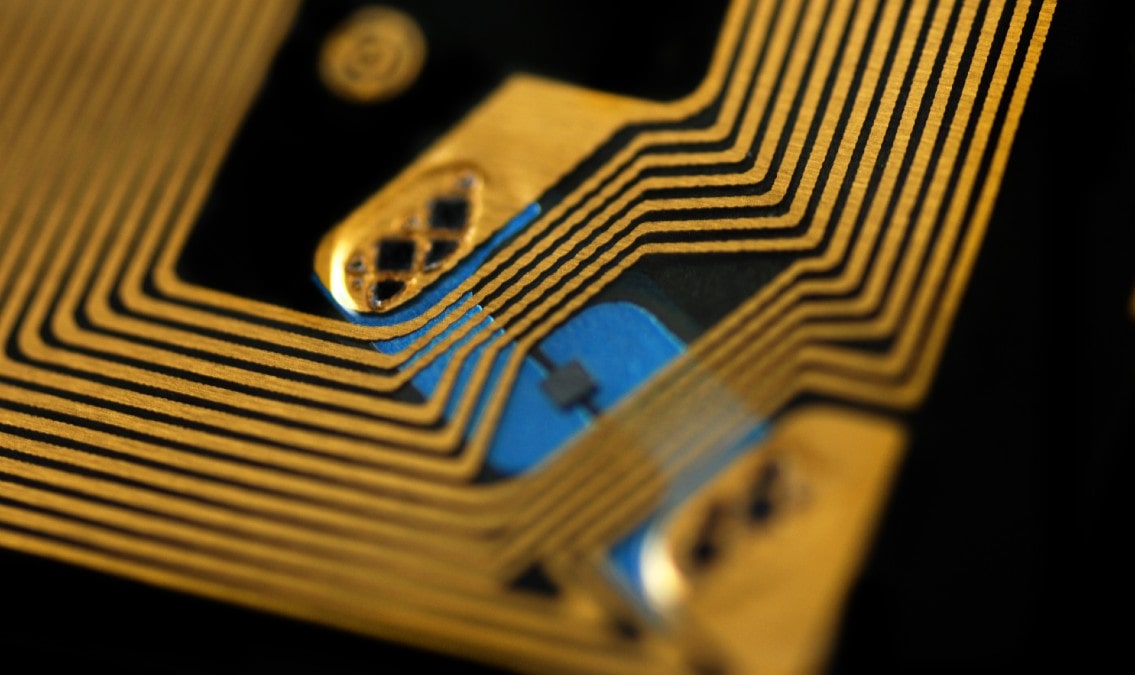

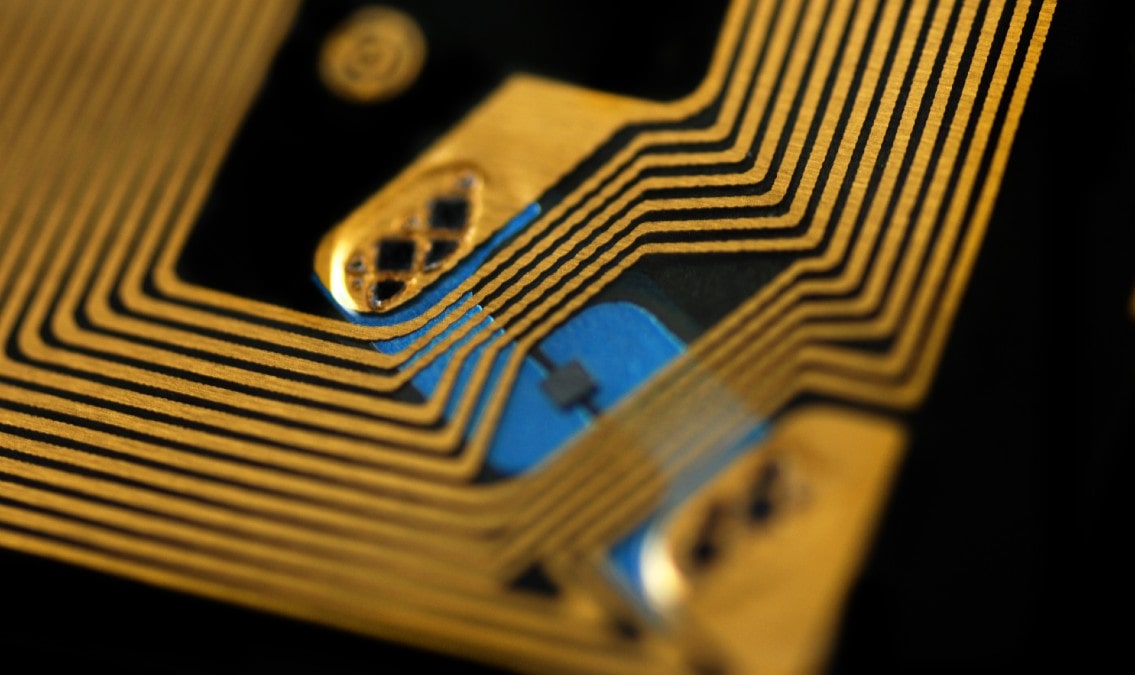

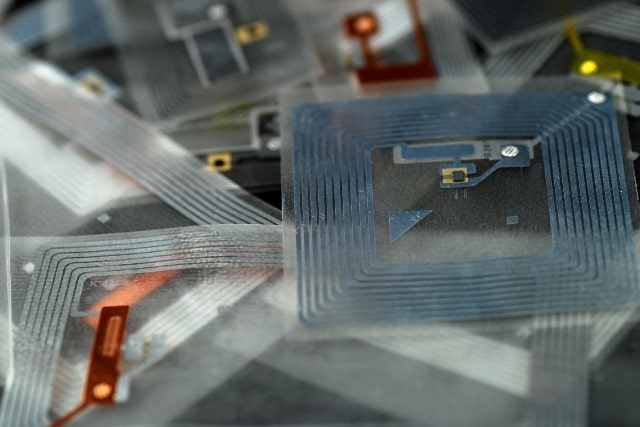

Every RFID system comprises two components: a smart label or tag and a reader. Many RFID labels and tags have an integrated processor and antenna to transmit data via radio waves to the reader. More complex RFID systems may have an external antenna that acts as a conduit between the tag and the reader.

The RFID tags are attached to the asset, but the type of attachment depends on the product. Once the reader receives the radio waves, it converts the encoded data into a readable form and passes it to a computer system for storage and use.

RFID systems can be very simple or extremely complex, which makes them suitable for various environments and applications. In fact, there are three types of RFID systems: active, passive, or semi-passive.

Active RFID tags require a continuous power source, so most have an internal battery lasting three to five years. Active RFID systems have long read ranges, durable tag options, and large memory capabilities, which makes them suitable for tracking expensive assets.

This is why they’re more popular in the manufacturing, logistics, and construction industries. However, active RFID systems tend to be more expensive because of their complex setup.

Unlike active systems, passive RFID tags don’t have a battery. Instead, the RFID reader transmits electromagnetic energy to the tag to transmit data.

Passive RFID systems have shorter read ranges, so they’re generally less expensive than active systems. Likewise, because the tags are smaller, passive RFID systems are more popular in small spaces.

Its affordability and simpler setup make passive RFID more popular for retail, hospitals, agriculture, and food service applications.

A semi-passive RFID system is a hybrid solution that uses a battery to power the RFID tag, which improves data transmission. The battery gives the tag a longer read range and more capabilities than a passive system.

However, unlike an active RFID system, a semi-passive system doesn’t have an onboard transmitter. Therefore, it has a more limited read range than an active RFID system. Semi-passive systems are a good compromise for applications that have a medium read range and require additional features.

Check out this video to learn more about the basics of RFID:

RFID has origins as far back as World War II, but the technology has only recently gained traction in commercial uses. More and more industries are realizing the benefits of opting for RFID tracking, especially in an era of digital transformation.

RFID has several advantages over other asset tracking solutions, including:

Despite its many benefits, RFID technology isn’t right for every organization. When considering an RFID system, you’ll need to account for the downsides of this technology, which include:

RFID technology has so many applications. While it’s particularly common in manufacturing for applications like asset tracking, other industries are also embracing this technology.

Learn more about RFID’s possibilities with these six use cases.

The retail industry uses RFID technology throughout the entire production, distribution, and sales process:

The healthcare industry adopted RFID for various applications, including:

A number of government agencies use RFID technologies to improve security.

For example, the government uses RFID in its identification tags to secure access to certain government buildings, departments, or military bases. RFID is also used to track and monitor hundreds of Government Furnished Property (GFP), such as law enforcement, research, and voting equipment.

RFID technology is also popular for livestock management. Using RFID on livestock increases animal health protects owners from major losses due to disease, and safeguards our food supply.

In fact, the USDA gave out over eight million RFID ear tags to farmers and ranchers in 2020, hoping that widespread adoption would protect the industry.

Farmers and ranchers use RFID ear tags to track individual animals, including cows, goats, sheep, and pigs. Traditional metal livestock tags require human analysis, but RFID tags speed up the process while reducing errors.

Farmers also use RFID tags to prevent the spread of disease in livestock. An RFID tag stores an individual animal’s entire health history, allowing for quick recognition of potential disease outbreaks. This immediate traceability is essential for managing quick-spreading illnesses in cattle.

Industrial RFID technology often uses more durable tags with longer read ranges than consumer-grade RFID tags. Manufacturers use this technology for:

The automotive industry uses RFID for both vehicle manufacturing and at the dealership level. This industry uses RFID for:

If your organization is considering investing in an RFID system, it’s important to understand that RFID isn’t a one-size-fits-all solution. Follow these tips to build an RFID system that generates tangible results for your business.

Do you need to improve inventory management in your retail store? Or do you want to track shipping for expensive industrial equipment?

You’ll need a very different setup for these applications. Understanding what you want to achieve with RFID will help you decide which RFID system to implement.

Your organization will need to choose between active, passive, or semi-passive RFID systems. The right choice comes down to your budget, physical setup, desired read range, and the nature of the items you’re tracking, for instance there are different considerations for RFID tool tracking vs other assets.

For RFID to be fully effective, your business needs software with quality reporting capabilities to manage RFID-captured data. This software should also integrate with any existing inventory or supply chain systems. Assess multiple software solutions to find the right fit for your RFID setup.

Every RFID system, no matter how simple, needs testing before implementation. You can test the system in a small location or on a small number of assets and then make any adjustments needed. Once you’ve optimized the RFID system on a small scale, it’s ready for launch on a larger scale.

RFID systems streamline business processes for a wide range of industries. As this technology continues to evolve, it’s becoming more accessible to more businesses than ever before. Even small businesses can take advantage of RFID tracking system solutions to do more in less time.

You’ll also need solid labels and tags to get the most returns from your investment in RFID. Camcode provides a range of durable RFID labels with human-readable and machine-readable codes. Check out our RFID labels to find the right setup for your business.

Can you track someone with RFID?

The short answer is yes, you can, as it’s possible to attach an RFID tag to both equipment and clothing. For example, if a person has a particular piece of equipment assigned to them and that equipment is required to be with them at all times, then it’s possible to track that person’s movements based on the location of the equipment.

How accurate is the location tracking of RFID technology?

When it comes to passive RFID tags, the reader needs to be within range of the tag in order for it to be detected. In this situation, you would know the tag is nearby, but most passive systems won’t be able to track its location. Many active RFID tags can be detected from a little more than half a mile, while the given location can be accurate to within roughly 10 feet.

Are RFID tags better than barcodes?

While there are benefits to RFID in some instances, barcodes still offer better and more reliable performance in many applications. In fact, it’s often recommended that barcodes be used in conjunction with RFID as a means to verify the RFID system’s data and as a backup should the RFID system fail.

Perhaps the biggest problem with barcodes is that each must be manually scanned. The scanner, therefore, has to be close to the item in question, requiring you to know its location and also to be within its line of sight. However, RFID comes with many challenges that make it unsuitable for various applications, such as:

In addition to its unsuitability for many common applications, RFID also poses other challenges, such as varying readable distances, meaning companies may need to choose many different RFID tag types to suit each asset’s surface.

Plus, while interference is a common issue, scanners can also be too sensitive, inadvertently scanning assets through a wall in another room. Finally, RFID tag configuration is complex, and if a scanner provides data on assets that were not found, it may corrupt the entire asset database.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.