3 Flaws of Using RFID for Military Asset Tracking

The U.S. military has strict requirements for tracking high-value assets such as weapons, explosive materials, ammunition, body armor, and other supplies. These requirements are set forth in standards such as MIL-STD-130 and MIL-STD-129.

There are two primary types of technologies used to track military assets: unique identification (UID) barcode labels and RFID tags. But are both technologies equally secure? In a recent investigation of how the U.S. military uses technology to track firearms and guns, the Associated Press (AP) found that RFID tags pose concerning security risks.

One of the most significant security risks associated with RFID tags is that they can be tracked by the enemy, allowing terrorists and other nefarious actors to locate soldiers or assets, and at distances significantly greater than what manufacturers claim. They can also be used to trigger an attack, such as a roadside bomb.

The AP conducted field tests in which two cybersecurity experts demonstrated that an RFID tag inside a rifle can be detected from a far greater distance than the few dozen feet claimed by manufacturers and contractors that install RFID systems. The U.S. government has restrictions on signal transmissions that were followed during field tests.

The AP points out that the enemy has no such constraints, and the cybersecurity experts who conducted the testing believe that the tags could be tracked from miles away.

In fact, one of the experts theorized that an RFID tag located on the outside of the International Space Station (ISS) could be tracked with a reader that had a sufficient power boost. The distance to the ISS? 250 miles.

What’s more, it doesn’t require expensive technology; RFID tags can be tracked using a few inexpensive items that can fit inside a backpack.

RFID tags don’t have anti-counterfeit features and are easy to fake, giving potential thieves an advantage in armories and gun rooms. RFID tags enable armorers to read all the tags in a row of firearms at once, which is one of the biggest advantages of the technology.

But it’s also a disadvantage in this case: RFID tags can be quickly and easily copied, even from outside a closed gun case. And replacing the gun with the fraudulent tag, a reader would count the firearm as being in inventory – even though it no longer is.

AP’s hackers demonstrated how this could be achieved in under two minutes.

While the scenario explored in the AP’s field tests demonstrates an increased security risk when it comes to insider theft, it could conceivably be replicated in the field. The black market is lucrative for arms dealers, and intentional diversion of weapons by arms dealers already poses problems for the U.S. military.

The ease of copying RFID tags only makes that practice easier to execute for bad actors, allowing them to replicate RFID tags to create the appearance that the weapons are still in the supply chain as expected. Stockpiles that aren’t closely monitored can also create opportunities for theft, with the ease of tracking RFID tags from potentially miles away, allowing terrorists to locate treasure troves of weapons and supplies with ease.

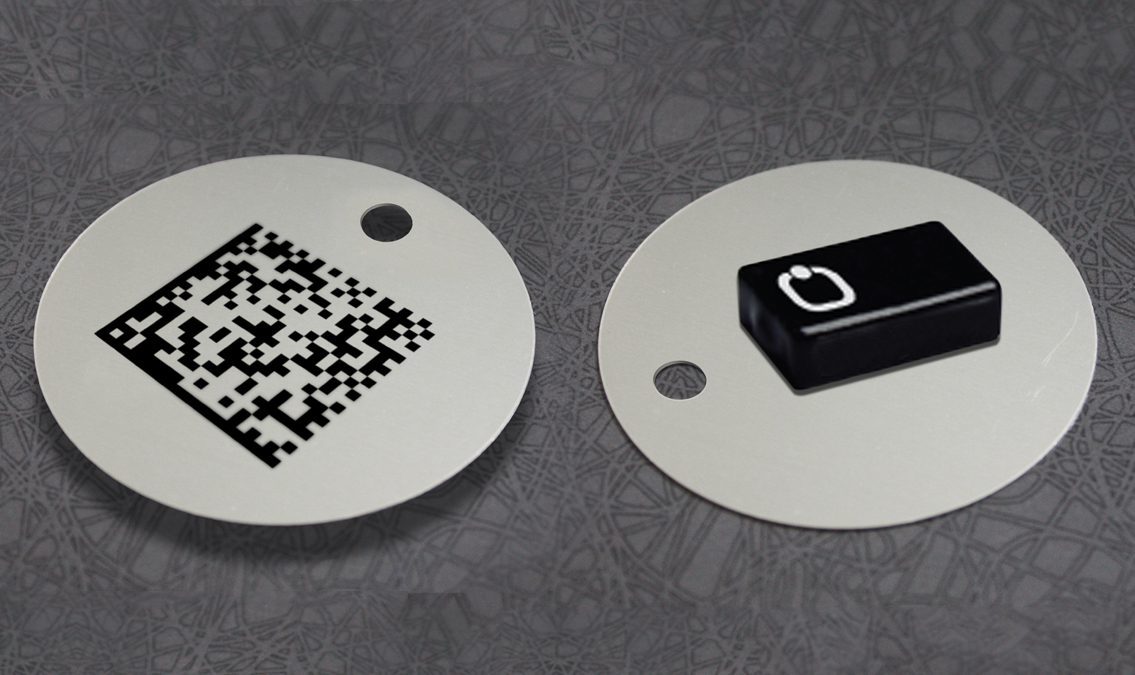

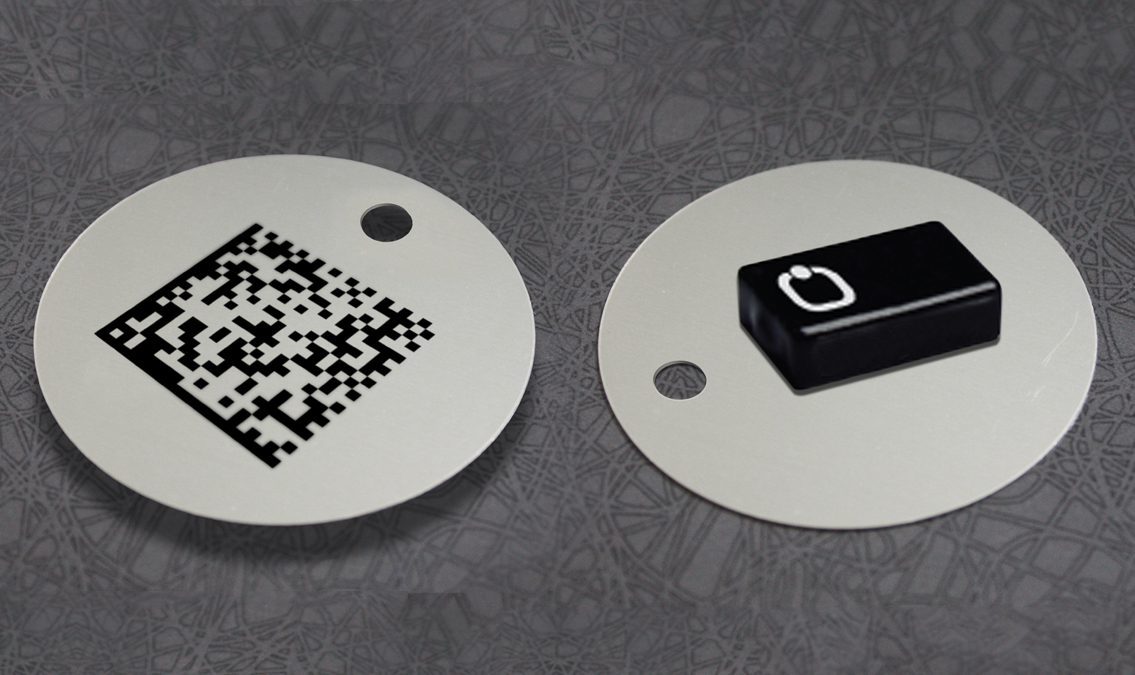

Metalphoto® barcode labels offer several advantages over RFID tags, particularly when it comes to durability and security. RFID tags lack durability, whereas Metalphoto anodized aluminum is one of the most widely specified materials for asset tracking in the defense industry and is certified for tracking more Department of Defense equipment than any other material in the world.

Metalphoto photosensitive anodized aluminum is also identified by the National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual as the most durable printed aluminum substrate available due to its excellent durability and ability to withstand extreme environmental conditions, including prolonged outdoor exposure, high temperatures, chemical exposure, saltwater, and abrasion.

Additionally, the Naval Surface Warfare Center (NSWC), Corona Division IUID Center studied 73 commercially available label materials, and in 32 out of 33 tests, Metalphoto earned the highest possible score – more top scores than any other material evaluated.

Metalphoto barcode labels can never be used to locate soldiers, locate assets, or trigger an attack, unlike RFID tags, especially if they’re printed in Camcode’s tactical low-visibility technology. These labels are specifically designed to mark sensitive items without compromising their zero detection/zero reflection footprints, maintaining the intended security of dangerous weapons and other valuable assets.

RFID tags are easy to fake, meaning they’re a poor theft deterrent. Metalphoto labels, on the other hand, can incorporate anti-counterfeit features that can’t be replicated. Upon examination, Metalphoto barcode labels can be verified for authenticity by evaluating the microprint, watermark, and other features.

RFID tags offer some benefits in certain applications, such as rapid inventory counts, but they fall short for applications requiring more durable and secure tracking technology, such as military asset tracking. Metalphoto barcode labels offer streamlined inventory management coupled with the durability and security that the Department of Defense and U.S. military applications demand, without making our troops more visible to the enemy in the field or leaving our high-value assets more vulnerable to theft.

Radio Frequency Identification (RFID) tags are an ideal asset tracking system in certain applications. However, RFID does have some inherent shortcoRadio Frequency Identification (RFID) tags are an ideal asset tracking system in certain applications. However, RFID does have some inherent shortcomings in functionality, durability and security. Click below to see the pros and cons of RFID, as well some alternatives that may be better suited to your particular tracking project.mings in functionality, durability and security. Click below to see the pros and cons of RFID, as well some alternatives that may be better suited to your particular tracking project.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.