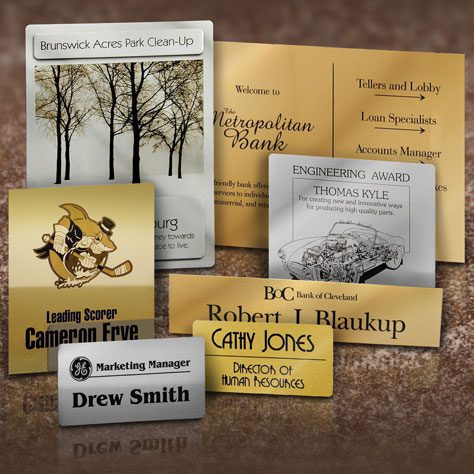

Metalphoto® Anodized Aluminum

The most durable printed aluminum substrate available, ideal for prolonged exposure to the harshest outdoor environments.

Trusted for Over 50 Years by The US Armed Forces, NASA, Caterpillar and Boeing

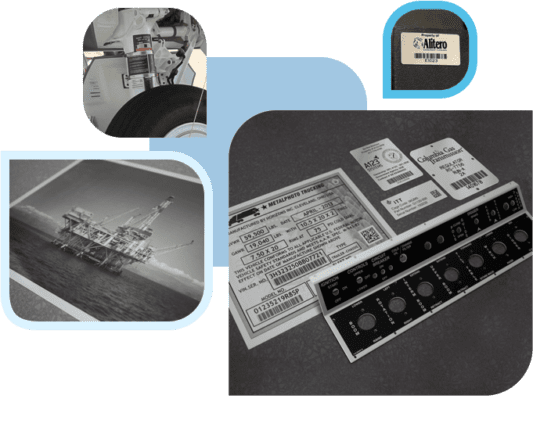

Metalphoto photosensitive anodized aluminum has been the “go-to” option for durable bar code labels, asset tags and nameplates for more than fifty years. The durability for which Metalphoto is known is the result of a unique manufacturing process in which a silver halide image is embedded within the sapphire-hard, anodic layer of the aluminum. The result is a bar code label which will function perfectly for years, maintaining its original appearance and scanning performance under an array of challenging conditions including extreme heat, humidity, long term exposure to weather, UV and other outdoor conditions, salt spray, abrasion, industrial solvents and chemicals and more. The National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual identifies Metalphoto photosensitive anodized aluminum as the most durable printed aluminum substrate available, citing its applicability for extreme environmental conditions and outdoor exposure.

See The Unmatched Durability and Image Resolution of Metalphoto

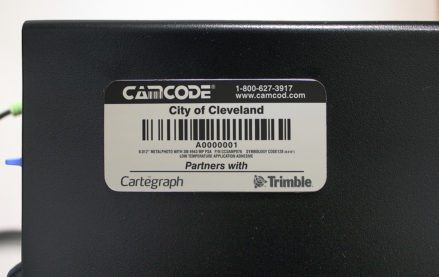

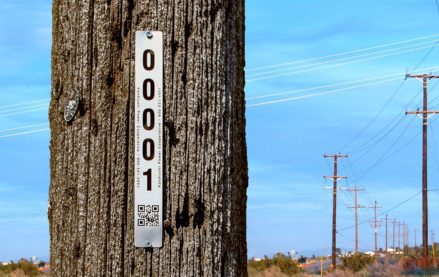

What makes Metalphoto truly unique among materials is its combination of unmatched durability, and it’s superior image resolution that allows it to display item unique barcodes, QR codes, serial numbers, and other variable information. View the videos below to see why Metalphoto has been trusted worldwide for over 50 years.

Field Proven to Last Over 20 Years and Meet the Most Demanding Specifications

Metalphoto satisfies wide ranging set of industrial, government and military specifications including MIL-STD-130 for Department of Defense UID data matrix bar code applications.

In fact, Metalphoto is the most specified label material in history for DoD applications (read more about its history with DoD Label Applications). Now it is the most requested product for durable UID labels and data plates requiring UID. That’s because the material is durable and the graphics are high contrast with excellent resolution. These are the best characteristics for data matrix bar codes for DoD applications attached with adhesive or mechanical fasteners.

Get a Free Asset Label Evaluation Kit

Request a free asset label sample kit today and we will send you a kit to test our extremely durable labels in your own operating environment.

Explore Our Most Popular Metalphoto Products

Find the most durable, custom-designed labels and improve the management and tracking of your assets. Don’t see what you need? Our product development team is on standby to help build your perfect label.

Metalphoto Has Been Trusted for Over 50 Years by Industry Leaders

Due to its strength and durability, Metalphoto is often selected for the most difficult and challenging applications. Find labels designed specially for your specific industry challenges. View All Industries ›

Metalphoto Performance Properties and Durability Characteristics

The tables below provide an overview of label performance. Refer to the durability characteristics presented lower on this page for additional details or contact us to discuss your specific bar code label, asset tag or UID label application.

| Metalphoto Photo-Anodized Aluminum Performance Properties | ||||

| Camcode® Product Choice | ||||

| Standard Processing (Image Intensified) |

Metalphoto XHT | Metalphoto with Teflon | ||

| UV Light:400 Hour QUV Weatherometer Exposure |  Excellent |

Excellent |

Excellent |

|

| Heat (°F / °C) |  650°F / 343°C |

1200°F / 649°C |

Up to 500°F / 260°C See Detail Below |

|

| Humidity |  Excellent |

Excellent |

Excellent |

|

| Salt Spray:5% NaCl solution at 90F for 700 hours |  Excellent |

Excellent |

Excellent |

|

| Abrasion:Taber abraser, 1000g Load, 7000 Cycles, CS17 Wheel |  Excellent |

Excellent |

Not Recommended Teflon Loss, Image OK |

|

| Paint Shedding |  Not Recommended |

Not Recommended |

Excellent See Detail Below |

|

| Organic Solvents:Extended immersion in alcohol, JP-4 jet fuel, hydraulic fluid, MEK and other organic solvents |  Excellent |

Excellent |

Excellent |

|

| Acid Solutions:24 hour room temperature immersion in 3% solutions of nitric acid, sulfuric acid and ferric chloride |  Excellent |

Excellent |

Excellent |

|

| Base Solutions:24 hour room temperature immersion in 3% solution of Clorox bleach |  Good |

Good |

Excellent |

|

| Strong Alkalies:24 hour room temperature immersion in 3% solutions of sodium and ammonium hydroxide |  Not Recommended |

Not Recommended |

Excellent See Detail Below |

|

| Note: Users must test products in the environment in which they are expected to function. ISG does not warrant the performance of its products in untested applications. | ||||

Metalphoto Durability Characteristics (Image Intensified)

| Specific Characteristic | Test Condition | Effect |

|---|---|---|

| Exterior Exposure | Black and silver image exceeds 400 hr. Weatherometer Test GG-P-455b, estimated equivalent to 20 yr. exposure | No Effect |

| Abrasion Resistance | Taber Abraser with CS17 wheel, a total of 1000 gm. load, 7000 cycles | Slight dulling of surface |

| Temperature Resistance | 650 F° | |

| Salt Spray | 5% at 95 F for 700 hrs.° | No Corrosion |

| Chemical Resistance | ||

| MIl-S-3136 111 Hydrocarbon Fluid | 1 hr. immersion | No Effect |

| MIL-L-5161C-Turbine and jet engine fuel | 1 hr. immersion | No Effect |

| JP-4 Fuel | 72 hr. immersion | No Effect |

| Kerosene | 12 hr. immersion | No Effect |

| Skydrol (Hydraulic Fluid) | 24 hr. immersion, at both room temperature and boiling point. | No Effect |

| Methyl Ethyl Ketone (MEK) | 24 hr. immersion | No Effect |

| Ethyl Acetate | 24 hr. immersion | No Effect |

| Xylol | 72 hr. immersion | No Effect |

| Heptane | 72 hr. immersion | No Effect |

| Ethyl Alcohol | 72 hr. immersion | No Effect |

| Ferric Chloride | 10% solution, 16 hr. immersion | No Effect |

| Ammonium Hydroxide | 10% solution, 16 hr. immersion | Slight dulling |

| MIL-P-21563 soap solution | 16 hr. immersion | No Effect |

| MIL-C-25179 AIN in heptane | 25% solution, 1 min. immersion (cleaning solution) | No Effect |

| Sulfuric Acid | 10% solution, 24 hr. immersion | No Effect |

| Phosphoric Acid | 1% solution, 12 hr. immersion | No Effect |

| Nitric Acid | 3% solution, 72 hr. immersion | No Effect |

| TSP (Trisodium Phosphate) | 1% solution, 40 hr. immersion | No Effect |

| Sodium Hydroxide | 1% solution, 1 hr. immersion | Not Recommended (surface attack) |

Metalphoto Durability Characteristics for XHT

| Specific Characteristic | Test Condition | Effect |

|---|---|---|

| Exterior Exposure | Black and silver image exceeds 400 hr. Weatherometer Test GG-P-455b, estimated equivalent to 20 yr. exposure | No Effect |

| Abrasion Resistance | Taber Abraser with CS17 wheel, a total of 1000 gm. load, 7000 cycles | Slight dulling of surface |

| Temperature Resistance | 1200 F° | |

| Salt Spray | 5% at 95 F for 700 hrs.° | No Corrosion |

| Chemical Resistance | ||

| MIl-S-3136 111 Hydrocarbon Fluid | 1 hr. immersion | No Effect |

| MIL-L-5161C-Turbine and jet engine fuel | 1 hr. immersion | No Effect |

| JP-4 Fuel | 72 hr. immersion | No Effect |

| Kerosene | 12 hr. immersion | No Effect |

| Skydrol (Hydraulic Fluid) | 24 hr. immersion, at both room temperature and boiling point. | No Effect |

| Methyl Ethyl Ketone (MEK) | 24 hr. immersion | No Effect |

| Ethyl Acetate | 24 hr. immersion | No Effect |

| Xylol | 72 hr. immersion | No Effect |

| Heptane | 72 hr. immersion | No Effect |

| Ethyl Alcohol | 72 hr. immersion | No Effect |

| Ferric Chloride | 10% solution, 16 hr. immersion | No Effect |

| Ammonium Hydroxide | 10% solution, 16 hr. immersion | Slight dulling |

| MIL-P-21563 soap solution | 16 hr. immersion | No Effect |

| MIL-C-25179 AIN in heptane | 25% solution, 1 min. immersion (cleaning solution) | No Effect |

| Sulfuric Acid | 10% solution, 24 hr. immersion | No Effect |

| Phosphoric Acid | 1% solution, 12 hr. immersion | No Effect |

| Nitric Acid | 3% solution, 72 hr. immersion | No Effect |

| TSP (Trisodium Phosphate) | 1% solution, 40 hr. immersion | No Effect |

| Sodium Hydroxide | 1% solution, 1 hr. immersion | Not Recommended (surface attack) |

Metalphoto Durability Characteristics For Laminated Teflon And Fused Teflon

| Specific Characteristic | Test Condition | EFFECT Laminated Teflon® FEP*** | EFFECT Fused Teflon® PTFE | EFFECT Fused Teflon® FEP*** |

|---|---|---|---|---|

| Exterior Exposure | Black and silver image exceeds 400 hr. Weatherometer Test GG-P-455b, estimated equivalent to 20 yr. exposure | No Effect | No Effect | No Effect |

| Abrasion Resistance | Taber Abraser with CS17 wheel, a total of 1000 gm. load, 7000 cycles | Not Recommended-Teflon Loss – Image OK | Not Recommended Teflon Loss – Image OK | Not Recommended Teflon Loss – Image OK |

| Paint Shedding | Excellent | Excellent | We Recommend Testing in Your Application | |

| Temperature Resistance | 300°F | 500°F | 400°F | |

| Salt Spray | 5% at 95 F for 700 hrs.° | No Corrosion | No Corrosion | No Corrosion |

| Chemical Resistance | ||||

| MIl-S-3136 111 Hydrocarbon Fluid | 1 hr. immersion | No Effect** | No Effect | No Effect |

| MIL-L-5161C-Turbine and jet engine fuel | 1 hr. immersion | No Effect** | No Effect | No Effect |

| JP-4 Fuel | 72 hr. immersion | No Effect** | No Effect | No Effect |

| Kerosene | 12 hr. immersion | No Effect** | No Effect | No Effect |

| Skydrol (Hydraulic Fluid) | 24 hr. immersion, at both room temperature and boiling point. | No Effect** | No Effect | No Effect |

| Methyl Ethyl Ketone (MEK) | 24 hr. immersion | No Effect** | No Effect | No Effect |

| Ethyl Acetate | 24 hr. immersion | No Effect** | No Effect | No Effect |

| Xylol | 72 hr. immersion | No Effect** | No Effect | No Effect |

| Heptane | 72 hr. immersion | No Effect** | No Effect | No Effect |

| Ethyl Alcohol | 72 hr. immersion | No Effect | No Effect | No Effect |

| Ferric Chloride | 10% solution, 16 hr. immersion | No Effect | No Effect | No Effect |

| Ammonium Hydroxide | 10% solution, 16 hr. immersion | No Effect | No Effect | No Effect |

| MIL-P-21563 soap solution | 16 hr. immersion | No Effect | No Effect | No Effect |

| MIL-C-25179 AIN in heptane | 25% solution, 1 min. immersion (cleaning solution) | No Effect | No Effect | No Effect |

| Sulfuric Acid | 10% solution, 24 hr. immersion | No Effect | No Effect | No Effect |

| Phosphoric Acid | 1% solution, 12 hr. immersion | No Effect | No Effect | No Effect |

| Nitric Acid | 3% solution, 72 hr. immersion | No Effect | No Effect | No Effect |

| TSP (Trisodium Phosphate) | 1% solution, 40 hr. immersion | No Effect | No Effect | No Effect |

| Sodium Hydroxide | 1% solution, 1 hr. immersion | No Effect* | No Effect* | No Effect* |

Top Surface Only – will react with exposed edge.

** Top Surface Only – exposed adhesive edges may soften or swell.

*** FEP should not be used in place of PTFE in applications where the label is exposed to high levels of radiation (>0.2 Mrad).

Note: Users must test Metalphoto products in the specific anticipated operating environment. Camcode does not warrant performance of its materials in any environment.

“We needed the ‘Swiss Army Knife’ of tags.”

“It was necessary to have an asset tag that could withstand the outdoor elements, yet was simple enough to meet basic tracking needs. We achieved both with Camcode’s asset tags.”

“We selected the Metalphoto option because it gave us the durability we needed.”

“We selected the Metalphoto option because it gave us the durability we needed in an active area where freight and equipment could come in contact with the barcode. The labels also have great barcode scanner readability.”

Discover Insights Into Metalphoto

Explore our blogs, buyer’s guides, specification sheets and more — and start learning more about why Metalphoto is trusted worldwide by industry leaders. View All Resources ›

Keep Operations Efficient with Metalphoto Barcode Asset Tracking Tags

If you’re having trouble finding the ideal tracking solution for your project or organization, build it with Camcode. Talk to our team today.