What is Facility Management? Core Functions, Challenges, Trends & More

Have you ever wondered how businesses keep their facilities running smoothly and efficiently? Facility management plays a crucial role in ensuring that buildings and infrastructure are well-maintained and operating at their best.

Facility management involves overseeing the maintenance, security, and overall operation of a building or facility. It encompasses a wide range of tasks, from managing utilities to coordinating maintenance schedules and ensuring compliance with safety regulations.

Effective facility management is essential for the success of any business. By properly managing facilities, organizations can improve productivity, reduce operational costs, and create a safe and comfortable environment for employees and customers. In this article, we’ll explore the key components of facility management and how it can benefit businesses of all sizes.

Facility management is the coordination of people, processes, and systems to ensure the functionality, comfort, safety, and efficiency of buildings and their supporting infrastructure. This includes managing maintenance, security, cleaning, catering, waste disposal, and other services to support the organization’s core activities.

Facility management is widely used across practically every sector to manage a variety of types of buildings and facilities, such as:

Significant sectors within facility management include healthcare, government, education, military and defense, and real estate, with real estate being the largest segment, followed by other unclassified industries. Education rounds out the top three and is followed by healthcare, military, and defense.

Government is the smallest sector in global facilities management, but it’s expected to experience progressive growth due to an increased government focus on infrastructure investments.

The healthcare sector is expected to see considerable growth due to an increase in healthcare facilities. Additionally, the real estate sector is expected to grow globally due to expansion in construction and development.

There are two main categories of facility management services:

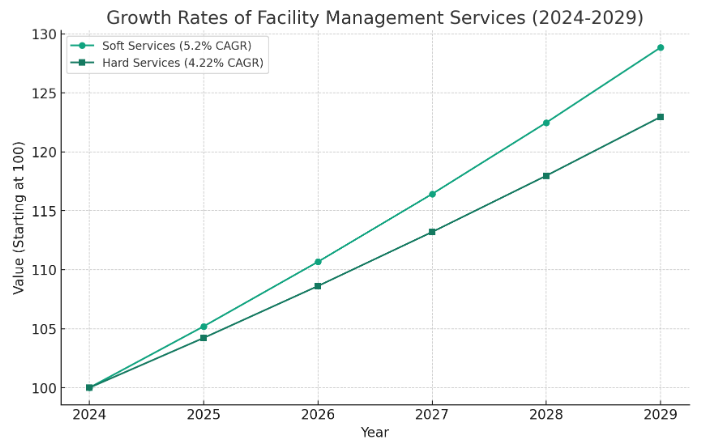

Based on data from Mordor Intelligence: Soft Facility Management Market and Hard Facility Management Market

According to ToolSense, hard services account for more than half of the global market, driven by the continued expansion of the global infrastructure market and the rapidly expanding building and construction services industry. However, soft services are the fastest-growing segment, with a projected CAGR of 5.2% from 2024 to 2029, compared to a projected 4.22% CAGR for the hard services segment during the same period.

Growth in the soft services segment of facility management is driven by increased investments in energy management, waste management, wastewater management, and similar services. Significant infrastructure development also creates additional demand for soft services.

Facility management plays a crucial role in the smooth operation and success of any organization, yet it’s often overlooked. From maintaining buildings and equipment to managing space utilization and ensuring compliance with health and safety regulations, facility management is essential for businesses of all sizes.

One key reason facility management is important in business operations is that it helps to create a safe and comfortable work environment for employees by addressing issues such as proper lighting, temperature control, and ergonomic workstations. A well-maintained facility not only reduces the risk of accidents and injuries but also supports effective collaboration, efficiency, and productivity.

Additionally, effective facility management can help businesses save money in the long run. By implementing preventive maintenance programs and energy-efficient practices, facility managers can reduce operational costs and extend the lifespan of equipment and infrastructure.

Regular inspections and repairs can prevent costly emergencies and downtime, ensuring business operations run smoothly without unexpected disruptions.

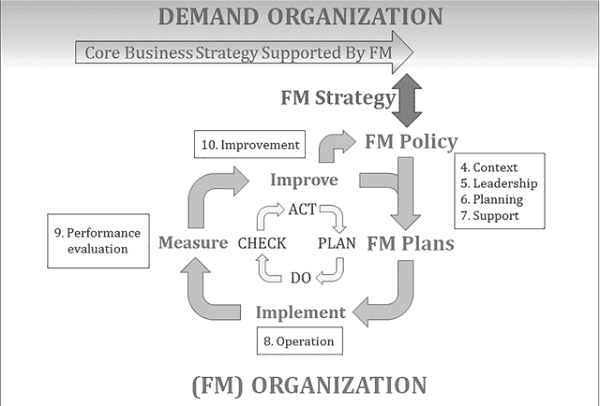

Screenshot via ISO

ISO 41001:2018, the International Standard for Facility Management Systems, is a quality standard specifically designed for the field of facility management. It’s the first international standard for facility management systems published by the International Organization for Standardization (ISO).

This standard provides a framework for organizations to establish, implement, maintain, and continually improve an effective facility management system. It covers a wide range of areas related to facility management, including strategic planning, stakeholder engagement, risk management, performance evaluation, and continuous improvement.

Implementing ISO 41001:2018 enables organizations to streamline processes and improve efficiency, ensuring that facility management practices are consistent, reliable, and meet the needs of stakeholders.

ISO 41001:2018 was amended in 2024 to incorporate climate change awareness and action changes, with the goal of integrating climate considerations into facility management systems. The current ISO 41001:2018 standard is set to be replaced by ISO/AWI 41001, which is currently under development.

By achieving ISO 41001:2018 certification, organizations can demonstrate their commitment to providing a high level of quality in facility management. Certification requires a thorough audit conducted by a certified third-party auditing body. This process involves assessing the organization’s facility management system against the standard’s requirements to ensure compliance.

Once an organization obtains certification, it can display the ISO 41001:2018 certification logo, demonstrating to stakeholders and customers that the company adheres to international best practices in facility management.

| Component | Key Tasks & Responsibilities |

|---|---|

| Daily Operations & Maintenance |

|

| Environmental Health & Safety (EHS) |

|

| Security |

|

| Sustainability & Energy Management |

|

| Asset Maintenance and Management |

|

| Space Planning and Utilization |

|

| Strategic Planning for Future Needs |

|

According to the International Facilities Management Association (IFMA), which adopts the ISO’s definition of facility management, “Facility Management is an organizational function which integrates people, place and process within the built environment with the purpose of improving the quality of life of people and the productivity of the core business.”

It encompasses a wide range of responsibilities, from ensuring the facility’s overall maintenance and upkeep to managing budget and expenses related to facility operations, overseeing safety and security protocols within the building, and coordinating with vendors and contractors for repairs and renovations. Here’s a closer look at the key elements of facility management.

Facility managers are tasked with overseeing the day-to-day building operations, such as electrical systems, HVAC, plumbing, and landscaping. They are responsible for managing preventive maintenance activities to ensure that all systems run smoothly and minimize disruptions, as well as corrective maintenance needs as they arise. This includes managing janitorial and maintenance contracts with third-party vendors.

Facility managers also create detailed reports and maintain systems to track maintenance and repairs, safety and compliance, inspections, and other processes and functions.

The environmental health and safety, or EHS, aspects of facility management include:

These responsibilities are carried out with the goal of maintaining a safe environment for both employees and visitors.

Facility security involves protecting the building’s infrastructure, physical space, and hardware and software components from both internal and external threats. The security component of facility management includes:

The aim of sustainability and energy management is to minimize the impact of a company’s operations on the environment. According to a report by the UN Environment Programme (UNEP), “Buildings use about 40% of global energy, 25% of global water, 40% of global resources, and they emit approximately ⅓ of GHG [greenhouse gas] emissions.”

Sustainability has become a key priority for many companies, and facility management is one of the primary areas where gains can be made. Sustainability and energy management includes:

These measures help reduce the operation’s environmental impact and can also reduce costs. For example, facilities that implement sustainable practices can lower their energy consumption, which translates to lower operating costs.

Asset maintenance and management is a function that often falls under the facility management umbrella. Predictive and preventive maintenance methods are vital to prevent equipment breakdowns before they occur, and regular maintenance helps to extend the useful lifespan of equipment and infrastructure.

Keeping equipment in optimal working condition and optimizing equipment utilization can also help to reduce operational costs. Asset maintenance and management include:

Facility management oversees an organization’s physical space, which includes planning for efficient space utilization. This includes:

Facility management plays a crucial role in the strategic planning for an organization’s future needs, ensuring that physical spaces and infrastructures align with long-term goals and adapt to changing requirements. This includes:

The current presiding global facilities management organization, the International Facility Management Association, calls for facility management leaders to take a more tactical and strategic approach to protect the future of the company’s properties.

In its Strategic Facility Planning white paper, the IFMA calls for facility managers to carry out SFP (strategic facility planning) as it “helps to avoid mistakes, delays, disappointments, and customer dissatisfaction.” In addition to safety and maintenance responsibilities, facility managers are encouraged to look beyond their normal duties so that they can better support operational efficiency.

To do this effectively, managers must compile two things:

Let’s take a look at how each one can better strengthen the overall productivity of the business:

Developing a comprehensive Strategic Facility Plan (SFP) requires:

The manager can operate as a true strategic support system if they are able to confirm each and every one of these benchmarks with the appropriate departments while implementing effective day-to-day practices. It is through the use of this blend of current and future that all parties involved can tackle changes as they arise as effectively as possible.

The Master Facility Plan (MFP), also known as a Facilities Master Plan, is a framework for planning the “physical environments that encompass the buildings.” Let’s explore what a holistic master plan looks like, taking into account both day-to-day tasks and future space needs.

Here’s what a Master Facility Plan should include:

The MFP should be regularly reviewed and updated. Facility managers should engage all departments that impact their facility so they can support their organization as it moves forward profitably.

Like any other discipline, facility management comes with its fair share of challenges. Here are some of the top challenges faced by facility managers.

Cost management is a challenge for facility management because there are so many variables to consider. From maintenance and repairs to utilities and supplies, there are numerous expenses that need to be carefully monitored and controlled.

Additionally, unexpected issues can arise that require additional funds to address, making it difficult to stick to a budget. Furthermore, facility managers need to balance cost management with providing a safe, comfortable, and functional environment for employees and customers. This can sometimes require investing in more expensive solutions in order to achieve long-term cost savings.

In the face of economic instability and budget constraints, facility management may not be seen as a critical investment by businesses, which can create additional cost restraints. Effectively managing facility costs requires a strategic approach and constant monitoring to ensure that expenses remain within budget.

Facilities require constant updates and upgrades to keep up with the latest technology. This can be costly and time-consuming for facilities managers, as they need to continuously assess and implement new technologies to improve efficiency and productivity.

Additionally, technological advancements can also pose security risks, as more connected devices and systems, such as IoT devices and cloud-based systems, increase the potential for cyber attacks. Facilities managers must stay informed about the latest cybersecurity threats and implement robust security measures to protect their facilities from potential breaches.

Technological advancements are particularly challenging in facility management because they have the potential to streamline operations and enhance the facility’s functionality, but at the same time, they require a significant investment of time and resources to effectively manage.

Sustainability requires a shift in mindset and practices toward more eco-friendly and sustainable operations. This may involve implementing new technologies, processes, and materials that can be costly and time-consuming.

Compliance with environmental regulations also adds another layer of complexity, as facility managers need to stay abreast of changing policies and ensure that their operations comply with these regulations.

The biggest challenge for modern organizations is balancing sustainability goals with operational and financial considerations. Sustainability initiatives often require long-term planning and investment, which can be difficult to prioritize in the face of immediate budgetary constraints.

Emergency preparedness requires a significant amount of planning, training, and resources to ensure that a facility is prepared for any type of emergency situation. Facility managers must conduct risk assessments, develop emergency response plans, provide training for staff, and invest in emergency equipment and supplies.

Additionally, facilities must comply with various regulations and standards related to emergency preparedness, which can be complex and time-consuming to navigate. In the event of an emergency, facility managers must be able to quickly and effectively respond to protect the safety of occupants and minimize damage to the facility.

The ever-changing nature of potential threats requires constantly updating and improving emergency response plans. This requires clear communication, coordination with emergency services, and the ability to make quick decisions under pressure.

As mentioned above, changing needs and demands present a prominent challenge in facility management, requiring constant adaptation and flexibility.

Facilities need to be able to respond to shifting priorities, regulations, and technological advancements to meet the needs of employees, customers, and stakeholders. This means that facilities managers must constantly assess and reassess their strategies, processes, and resources to ensure they are providing an optimal environment for the people using the facility.

Failure to anticipate and address changing needs can lead to inefficiencies, dissatisfaction among employees and visitors, and ultimately, an impact on the organization’s overall success. Staying ahead of evolving trends and demands is essential for effective facility management.

Staffing and hiring require finding individuals with a specific set of skills and experience in areas such as maintenance, engineering, and operations. Additionally, facility management roles often involve a wide range of responsibilities, from ensuring compliance with safety regulations to managing budgets and overseeing projects.

Finding candidates who are not only qualified but also culturally fit with the organization can be a time-consuming process. Furthermore, turnover rates in facility management tend to be high due to the demanding nature of the job, which means that constant recruitment and training efforts are necessary to maintain a fully staffed and capable team.

Having a well-thought-out facility management plan is crucial for maintaining the functionality and efficiency of any building or property. Follow these key steps to implement an effective facility management plan.

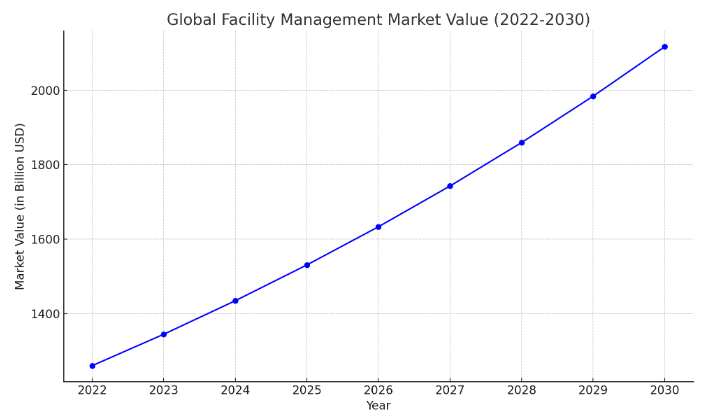

Based on data from Fortune Business Insights

Managing facilities efficiently is crucial to ensuring smooth operations and maximizing productivity. Facility management software has emerged as a powerful tool that enables organizations to streamline their facilities management processes, improve asset performance, and reduce costs.

In fact, the global facility management market was valued at $1,260.0 billion in 2022 and is expected to grow at a CAGR of 6.7%, reaching $2,031.4 billion by 2030.

Facility management software helps organizations manage their facilities, assets, and maintenance processes more effectively. It provides a centralized platform where facility managers can track and monitor various aspects of their facilities, such as equipment maintenance, space utilization, energy consumption, and vendor management.

| Type of Software | Key Features |

|---|---|

| Computer-Aided Facility Management (CAFM) |

|

| Computerized Maintenance Management Systems (CMMS) |

|

| Enterprise Asset Management (EAM) |

|

| Integrated Workplace Management Systems (IWMS) |

|

Facility management software comes in various forms, from software focused on a specific function such as asset management to comprehensive, integrated facility management solutions that encompass all the core functions of facility management. Here’s a look at the most commonly used types of facility management software.

CAFM software is a tool used by facility managers to efficiently manage and maintain their buildings, assets, and workplace environments. This type of software integrates various aspects of facility management, such as space planning and allocation, maintenance management, asset tracking, and resource management and scheduling, into one centralized platform.

CAFM software streamlines workflows and improves overall productivity by providing real-time information on building operations and maintenance. With this software, managers can easily track key metrics, generate reports, and make informed decisions to optimize building performance and reduce costs.

The benefits of CAFM solutions include:

CMMS software, or a centralized maintenance management system, centralizes information about an organization’s maintenance operations. It helps optimize the use and availability of equipment such as vehicles, machinery, and other physical assets.

CMMS systems are designed to simplify the maintenance process by providing tools and features that streamline tasks such as work orders, inventory management, asset tracking, and scheduling.

At its core, a CMMS is used to track and manage maintenance activities, from routine inspections to major repairs. By centralizing all maintenance-related data in one system, organizations can better organize their maintenance operations, improve workflow efficiency, and reduce downtime.

Key features of a CMMS include preventive maintenance scheduling, which allows users to create maintenance schedules for equipment based on time or usage triggers; work order management, which enables users to create, assign, and track maintenance tasks; inventory management, which helps users keep track of spare parts and supplies needed for maintenance; and reporting and analytics, which provide insights into maintenance performance and help identify areas for improvement.

The benefits of a CMMS include:

Enterprise Asset Management (EAM) software is a comprehensive solution that helps organizations manage their physical assets throughout their lifecycle. These assets can range from equipment and machinery to vehicles and buildings. EAM software enables businesses to track, maintain, and optimize their assets to ensure they are operating efficiently and effectively.

Asset tracking is a key feature of EAM. It allows businesses to monitor where their assets are located, who is using them, and how they are being utilized. With this information at their fingertips, organizations can make more informed decisions about their assets and maintenance needs.

Another key function of EAM is maintenance management. It allows businesses to schedule routine maintenance for their assets, track work orders, and ensure that all maintenance tasks are completed on time.

EAM software also provides valuable insights into asset performance and usage. By analyzing data collected from the software, organizations can identify trends, make predictions, and optimize their asset management strategies.

The benefits of EAM software include:

IWMS solutions provide a comprehensive suite of tools to manage all aspects of facility and real estate management. They integrate functionalities for real estate management, capital project management, facility space management, maintenance management, and environmental sustainability.

IWMS software enables facility managers to streamline their processes, improve efficiency, and make data-driven decisions to optimize the use of their workspace. One key feature of an IWMS is its ability to centralize data and generate insightful reports on various aspects of facility management. This includes information on space utilization, maintenance schedules, energy consumption, lease agreements, and compliance with regulations.

An IWMS can also automate routine tasks and workflows. For example, maintenance requests can be automatically routed to the appropriate personnel, work orders can be scheduled and tracked, and inventory levels can be monitored in real-time.

An IWMS also helps organizations ensure compliance with health and safety regulations, environmental standards, and industry best practices. By providing tools for tracking and reporting on these aspects, facility managers can proactively address any issues and maintain a safe and sustainable work environment for employees.

The benefits of an IWMS include:

Facility management is subject to various regulations and laws to ensure safety, compliance, and efficiency within the workplace. These regulations cover a wide range of aspects, from health and safety measures to regulations related to equipment.

The regulations applicable to a specific organization depend on the industry, location, and size of the business. Regulations are set forth by multiple entities.

On top of international and federal regulations, state and local regulations may also apply to specific industries or across the board for businesses and employers. Needless to say, compliance is multi-faceted and incredibly complex, requiring a comprehensive management strategy.

Let’s review some best practices for implementing and maintaining a strong facility management compliance program.

Facilities managers must stay informed about relevant laws, regulations, and codes that apply to their industry. Laws can vary depending on the location and type of facility, so it’s important to monitor updates and changes in regulations regularly.

As mentioned above, there are many regulations that facilities may be required to comply with, so the first step in developing a robust compliance program is to understand what regulations apply to your facility.

For example, the UK government introduced The Management of Health and Safety at Work Regulations in 1999, which apply to employers in the UK, while U.S.-based businesses are subject to OSHA (Occupational Safety and Health Administration) regulations and the Americans with Disabilities Act (ADA). There are also international and national labor laws created by the International Labour Organization (ILO) and the U.S. Department of Labor, respectively.

The U.S. healthcare sector must comply with HIPAA (Health Insurance Portability and Accountability Act of 1996) regulations, and food manufacturing facilities, medical device manufacturers, and pharmaceutical facilities are subject to regulations set forth by the Food and Drug Administration (FDA).

Start by identifying all applicable regulations and laws, considering organizational, reputational, and strategic risks.

Conduct internal audits to assess your compliance with these regulations and the effectiveness of your security and compliance strategies.

Conducting regular audits of your facility can help you identify areas where you may be falling short of regulatory compliance. These audits should cover everything from fire safety regulations to environmental laws to ensure that your facility is meeting all necessary requirements.

Developing a comprehensive compliance plan requires a clear understanding of your compliance status and the regulations you need to comply with. This plan should outline the specific regulatory requirements that apply to your facility and the steps you will take to ensure compliance. Prioritize your actions based on the most critical compliance requirements and risks.

It should also clearly define the responsibilities of all stakeholders involved. This plan should be regularly reviewed and updated as regulations change.

Develop safety and compliance checklists that clearly outline the steps to take in certain situations. Some commonly used safety and compliance checklists in facility management include:

Of course, the checklists you develop will depend on the regulations that apply to your organization as well as your company’s internal policies and procedures.

Each item on the checklist should be specific, measurable, and actionable, leaving no room for ambiguity. Regularly review and update the checklist to reflect changes in regulations, facility modifications, or lessons learned from incidents, and ensure that checklists are readily available to employees and stakeholders.

For example, you might post a fire safety checklist or evacuation plan near the emergency exits in your facility or attach durable instructional labels to equipment. These labels can be printed with essential safety, operational, or compliance steps to promote workplace safety and compliance.

Educate your employees about compliance policies, procedures, and standards. All staff members involved in facilities management should receive training on regulatory compliance. This training should cover the specific regulations that apply to your facility and the procedures and protocols that need to be followed to ensure compliance.

Regular training ensures that employees understand their roles in maintaining compliance and are updated on any regulatory changes or updates to company policies.

Keeping detailed records of your facilities management activities, including maintenance schedules, inspections, and repairs, is essential for demonstrating regulatory compliance. Make sure that all documentation is easily accessible and up-to-date.

Establish effective communication channels for reporting compliance issues or concerns without fear of retaliation. Implement monitoring and auditing systems to continuously assess the effectiveness of your compliance program and identify risks.

Regular reviews and updates to the program are essential to adapt to changes in regulations and business operations.

Utilize regulatory compliance software (or facility management software with compliance management capabilities) to automate and streamline compliance processes. This can simplify the management of regulatory changes, policy updates, and compliance assessments. The right software can also provide valuable insights and analytics to improve decision-making and ensure continuous compliance.

Establish clear procedures for enforcing compliance policies and taking corrective action in case of non-compliance. Accountability at all levels ensures that compliance is taken seriously and that any issues are addressed promptly to prevent recurrence.

Clearly communicating your organization’s code of conduct and ensuring it reflects your organizational values, regularly communicating changes, and implementing effective training and employee engagement programs are all part of building a culture of compliance. Following these practices and the best practices outlined above helps to minimize compliance violations and promotes a positive working environment.

If you’re unsure how to ensure regulatory compliance in your facility, consider working with compliance experts who specialize in facilities management and have experience in your industry. These experts can provide guidance and support to help you meet all necessary requirements.

| Trend | Opportunities | Challenges |

|---|---|---|

| Smart Buildings |

|

|

| Cloud-Based Solutions |

|

|

| Sustainability & Green Initiatives |

|

|

| Employee Well-Being |

|

|

| Flexible Workspaces |

|

|

| Increasing Building Standards |

|

|

A variety of trends and technologies are shaping facility management, revolutionizing the way facilities are operated and maintained. Let’s examine some of the biggest trends in facility management and the challenges and opportunities they present for facility managers and operators.

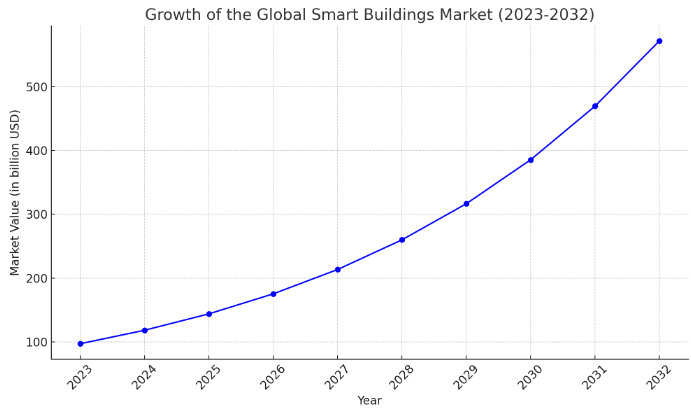

Based on data from Fortune Business Insights

The global smart buildings market has grown significantly. It was valued at $96.96 billion in 2023, and it’s projected to grow at a CAGR of 21.8%, from $117.42 billion in 2024 to $568.02 billion by 2032.

The rapid adoption of smart technologies marks a shift towards more efficient, sustainable, and user-friendly environments. This transformation is driven by the integration of Internet of Things (IoT) devices, artificial intelligence (AI), machine learning (ML), and other digital innovations into the physical infrastructure of facilities.

While the benefits are substantial, the rapid adoption of smart building technologies also presents challenges, such as the significant upfront investment, potential cybersecurity risks, and the requirement for ongoing management and updating of these systems.

These advanced systems require facility managers to have a solid grasp of building information systems, and there’s a growing need for skilled personnel who can manage and optimize them.

Cloud-based solutions are a major driver in the industry, offering opportunities for efficiency, scalability, and integration. These solutions allow facility managers to access and analyze data from anywhere, make informed decisions in real time, and improve the overall management and operation of facilities.

As with any technology that relies on internet connectivity, cloud-based solutions introduce risks related to data security and privacy. Ensuring the protection of sensitive information and compliance with data protection regulations is paramount.

The effectiveness of cloud-based solutions is heavily reliant on consistent and high-speed internet access. Interruptions in connectivity can hinder access to the systems and data needed for facility management.

In the modern world, sustainability and Environmental, Social, and Governance (ESG) reporting have become crucial aspects of facility management, driven by both regulatory and societal pressures. With the increasing focus on corporate responsibility and environmental impact, organizations are being held more accountable for their operations and the effects they have on the environment and society.

Sustainability and ESG reporting in facility management play a significant role in ensuring that businesses are operating in a way that is not only profitable but also responsible and ethical.

Unlike financial reporting, there is no universal set of standards for reporting on sustainability and ESG factors. This can make it difficult for facility managers to know what data to collect and how to report on their sustainability performance in a consistent and meaningful way.

Another challenge is the complexity of collecting and analyzing data on sustainability and ESG factors. It involves tracking a wide range of data points, from energy and water consumption to waste management and indoor air quality, which may be spread across multiple systems and sources. This makes it challenging to aggregate and analyze in a timely and accurate manner.

Different stakeholders sometimes have differing priorities and expectations related to sustainability, which can be difficult to balance.

Today’s companies are increasingly prioritizing employee and occupant well-being, with initiatives aimed at creating productive and satisfying work environments through ergonomic workspaces and indoor air quality monitoring.

The upfront costs of purchasing ergonomic furniture, upgrading HVAC systems for better air quality, and implementing other wellness-focused changes can be significant. However, it’s difficult to quantify and measure the direct impact of wellness initiatives on productivity, employee satisfaction, and health outcomes, which can make it challenging to monitor and adjust strategies.

Facility managers may find it challenging to demonstrate immediate returns on investment to stakeholders, as benefits such as increased productivity and reduced absenteeism may take time to become evident, making it challenging to justify further investment.

Space and infrastructure limitations can also pose challenges when it comes to implementing these initiatives. For instance, older buildings may have limitations that make it difficult to implement modern ergonomic solutions or improve air quality without substantial renovations.

Flexible workspaces are work environments that are adaptable and can be easily reconfigured to meet the changing needs of a business or organization. These spaces are designed to enable employees to work in a variety of settings, whether it be in a traditional office space, a collaborative area, a quiet zone, or even remotely.

Flexible workspaces come with challenges, such as managing noise levels, ensuring adequate privacy, and maintaining a sense of community and team cohesion. For example, it’s often challenging to find the right balance between open spaces, collaborative areas, and quiet zones can be challenging. Too much of one type of space can lead to underutilization of others, affecting overall productivity.

It can also be difficult to manage shared resources efficiently, such as ensuring that all employees who need it have access to private office space at the same time or that enough conference rooms are available for scheduled meetings.

Data security is also a potential concern. With employees moving around and using different workstations, ensuring secure and reliable access to networks and data is more complicated. The risk of data breaches may increase if proper cybersecurity measures are not in place.

In recent years, building standards and regulations have become increasingly strict in order to promote sustainability, energy efficiency, and overall safety. Regulations such as California’s A.B.2446, which requires new buildings to conduct lifetime environmental impact studies and make these findings public, signify a broader shift towards sustainability and transparency in the construction and facility management industries.

This trend is growing, as governments around the world are imposing stricter building standards to combat climate change, reduce energy consumption, and minimize facilities’ environmental footprints. While these regulations are important for the environment and public safety, they have a direct impact on facility management.

For example, A.B.2446 requires the entire building lifecycle to be considered from the start, from using sustainable construction materials and methods to optimizing operational energy consumption and sustainable methods for eventual decommissioning. The aim is to reduce embodied carbon emissions, which account for an estimated 11% of global energy-related carbon emissions, according to the Natural Resources Defense Council (NRDC).

According to the U.S. Green Building Council, “In the buildings context, embodied carbon refers to the greenhouse gas (GHG) emissions generated by the manufacturing, transportation, installation, maintenance and disposal of building materials.”

As mentioned earlier in this guide, ISO 41001:2018, the International Standard for Facility Management Systems, was amended in 2024 to incorporate climate change awareness and action considerations. These changes apply not only to facility management but all existing and upcoming ISO Management Systems Standards (MSS).

Companies pursuing ISO 41001:2018 certification will need to incorporate these considerations into their business practices. The amendments, added to Clauses 4.1 and 4.2 of the current Annex SL Standards, include:

As public awareness grows, the pressure on lawmakers to pass stricter building codes and legislation to combat climate concerns.

Stricter building standards often require more advanced systems and technologies to be installed in buildings, such as energy-efficient HVAC systems, smart building controls, and renewable energy sources. Preventive maintenance becomes critical to ensuring systems operate at peak efficiency, reducing energy consumption, and prolonging the lifespan of building components.

Stricter building standards can also impact the overall design and layout of buildings, and maintenance procedures must be adapted accordingly. For example, buildings with more stringent fire safety regulations may require more frequent fire drills and inspections, while buildings with enhanced energy efficiency standards may need to have their systems serviced more frequently.

With the requirement to disclose environmental impacts, there is an increased need for accurate data collection, monitoring, and reporting. Facility managers must implement systems to track energy consumption, water usage, waste generation, and other environmental metrics. On the plus side, this data can also help identify opportunities for improvement and demonstrate sustainability efforts to stakeholders.

Facility management is a comprehensive discipline crucial for the successful operation and growth of organizations in every business sector. Effective facility management enhances the safety and productivity of workspaces and plays a pivotal role in reducing operational costs and environmental impact.

As we look to the future, the importance of facility management in enhancing business operations, reducing environmental impact, and improving the quality of work environments cannot be overstated. The ongoing development of new technologies and the increasing focus on sustainability and flexibility will continue to drive innovation in this field, presenting both challenges and opportunities in facility management.

Facilities managers are responsible for ensuring that the buildings and services meet the needs of the people who work in or visit them. They manage services such as cleaning, security, and parking, and ensure that the environment is safe and efficient.

Their role includes maintaining, operating, and improving buildings, ensuring that facilities comply with laws and regulations, and managing budgets and contracts related to building services.

Determining the success of facility management involves measuring performance against specific goals and objectives. Key performance indicators (KPIs) might include operational efficiency, cost savings, compliance with regulations, occupant, visitor, or employee satisfaction, and sustainability metrics.

For example, cost savings can be measured by comparing the facility management budget to actual expenses and seeing if there are any reductions in costs. Efficiency improvements can be evaluated by analyzing how well resources are being utilized and whether there are any bottlenecks in operations. Regular audits, feedback from users, and comparisons with industry benchmarks are also crucial.

The quality standard for facility management is often benchmarked against the ISO 41001:2018 standard. This international standard provides a framework for establishing, implementing, maintaining, and improving an effective facility management system, focusing on efficiency, safety, and sustainability.

Facility management compliance involves ensuring that a facility’s operations and practices align with all relevant laws, regulations, and industry standards. This includes everything from safety regulations to environmental policies to building codes.

Facility managers must stay current on compliance requirements and ensure that their facilities always meet these standards. Failure to comply with regulations can result in fines, penalties, or even legal action, making compliance a critical aspect of successful facility management.

A facility management plan is a comprehensive document that outlines the strategies and procedures for managing and maintaining a facility. It includes information on how the facility will be operated, maintained, and repaired to ensure that it remains in optimal condition.

The plan may cover areas such as preventative maintenance schedules, emergency response protocols, security measures, energy efficiency strategies, and budgeting for maintenance and repairs. A well-developed facility management plan is essential for ensuring that a facility operates efficiently and effectively and that it meets the needs of its occupants.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›