What is a Computerized Maintenance Management System (CMMS)?

Maintenance is an essential part of owning equipment. Regardless of your industry or hardware, regular maintenance is a best practice for making the most of your investment.

However, managing all maintenance tasks at scale can be challenging. That’s why more organizations are embracing computerized maintenance management systems (CMMS) to assign work orders, track equipment health, and much more.

Adding a CMMS to your workflows may feel like an additional solution to maintain, but it’s a best practice that puts maintenance on autopilot, making the most of both your equipment and costs.

In this guide, we’ll explain how CMMS work and why they’re so beneficial. We’ll also share expert tips on how to choose the best CMMS for your needs and offer best practices for CMMS return on investment (ROI).

| Metric | Details |

|---|---|

| 2022 Market Size | $1.06 billion |

| Projected Growth | 10.9& CAGR from 2023 to 2030 |

| Growth Drivers |

|

| Key Capabilities |

|

A Computerized Maintenance Management System (CMMS) schedules, tracks, and monitors maintenance activities to provide cost, component item, personnel, and all reporting history. CMMS systems interface with production scheduling and cost systems and are often used to follow system-wide preventive maintenance in government or large enterprises.

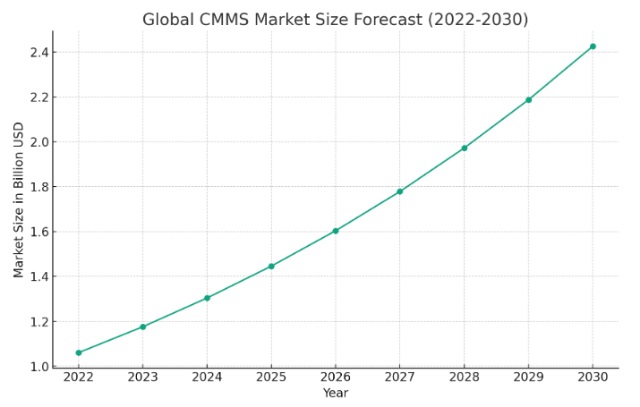

This is a growing area of demand for enterprises and small businesses alike. In fact, the global CMMS market size was valued at $1.06 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 10.9% from 2023 to 2030.

Based on data from Grandview Research

CMMS systems include key functionalities such as:

In recent years, the increasing complexity of facilities and the need for improved efficiency have made CMMS indispensable for facilities that need 24/7 reliability.

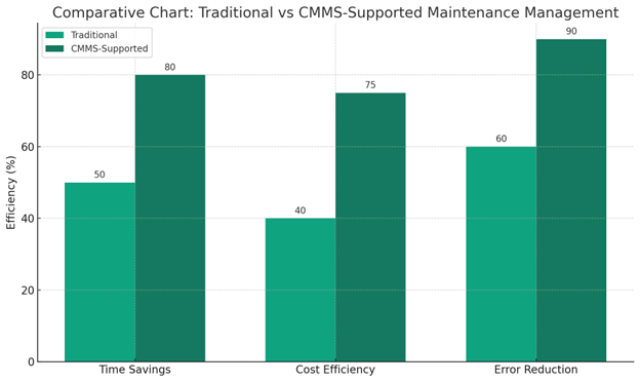

Computerized maintenance management systems offer numerous benefits to companies, including a reduction in maintenance costs. Compared to traditional maintenance management without a CMMS, a technology-first approach leads to a 30% gain in time saved, a 35% improvement in cost efficiency, and an impressive 30% gain in error reduction.

Unplanned equipment downtime costs an average of $260,000 an hour, which is no small sum for any business. Since aging equipment and mechanical failure are the leading causes of unplanned downtime, solving these issues with a CMMS can lead to tremendous cost savings.

While cost reduction is a tremendous win for any organization, CMMS platforms come with multiple benefits that make your organization more efficient.

CMMS enable streamlined recording of data related to your company’s valuable assets and property, such as equipment and infrastructure assets. Asset management using CMMS allows you to ensure warranties are up to date, monitor the value of spare parts, and oversee service and warranty contracts.

However, it’s essential to have a tool that bridges physical hardware with CMMS software. Marking assets and points of maintenance with durable barcode labels or Metalphoto® anodized aluminum asset tags can help manage relevant data, allowing your company to keep maintenance management programs up to date.

In addition to monitoring maintenance and repairs for high-value, fixed assets, CMMS provides a framework for managing inventory, including spare parts, supplies, and other materials needed for production or service provision.

Effective inventory management prevents unexpected downtime caused by out-of-stock spare parts. Some CMMS also provide solutions for tracking shipments, managing purchase orders, and monitoring stock and inventory levels on an ongoing basis.

Your company’s high-value assets have an expected lifespan, but failing to provide ongoing preventative maintenance can shorten equipment lifecycles and require premature replacements. Preventative maintenance is possible without a CMMS, but 80% of companies with a preventive maintenance strategy credit their CMMS for their improved productivity.

A CMMS can help you monitor and manage ongoing preventative maintenance to ensure these valuable assets are in optimal working order. Fifty-nine percent (59%) of organizations with preventive maintenance strategies use a CMMS for this exact purpose.

Regardless of your industry, you’re beholden to regulatory guidelines. Risk mitigation and compliance are multi-faceted, but instituting a CMMS provides a much-needed foundation for proper auditing and reporting. CMMS helps organizations comply with regulations by following better maintenance practices and record-keeping, simplifying the compliance process.

Computerized maintenance management systems integrate with other business systems. With the right setup, organizations can automate key processes like inventory reorders, shift scheduling, and work order assignments.

Not only that, but automations and integrations streamline the exchange of data across systems, reducing the odds of errors and miscalculations.

Regular maintenance ensures that equipment operates safely and within industry standards, reducing the risk of accidents. The CMMS assigns and schedules maintenance tasks and keeps records of all maintenance procedures, safety standards, and compliance requirements.

The recordkeeping function ensures all maintenance happens in accordance with your established safety guidelines. If there’s ever an incident, the CMMS tracks and analyzes it, helping you take corrective measures to prevent future occurrences.

With careful planning, a CMMS will reduce equipment downtime. This tool improves the performance of your company’s equipment and maximizes the usable lifespan of your most expensive assets through regular maintenance and repairs.

CMMS also allows for improvements in quality rate. By monitoring equipment usage, you’ll gain valuable data on the actual effectiveness and quality of your equipment.

Tracking data such as the number of hours per 100 hours that a piece of equipment operates at expected quality standards provides key insights that can help drive future decision-making and planning. This allows you to optimize the use of your existing assets and make sound purchasing decisions.

Worth noting: while a CMMS primarily concentrates on organizing and tracking maintenance tasks, an EAM (Enterprise Asset Management) solution extends even further to manage every phase of an asset’s lifecycle, from procurement to eventual retirement.

Learn more about the differences of a CMMS vs EAM.

There seem to be just as many CMMS software solutions as organizations that need to use them, which can make selecting the right one seem daunting. Consider these factors to choose the best CMMS for your organization.

Of course, before you delve any more deeply into your options, you need to calculate the price and return on investment (ROI) over the software’s lifetime, which will limit your choices.

Consider your budget for a CMMS solution. It’s a good idea to calculate the total cost of initial implementation as well as the cost of maintaining the software itself.

You may need to purchase additional hardware, like scanners, to implement the CMMS. Take these costs into account to come up with a rough budget before shopping around. Careful budgeting will help you select the best long-term solution for your organization.

One of the best ways to choose a CMMS software system is to consider the size of your organization. You don’t want a CMMS that’s too big for your company; you’ll get bogged down in figuring out all the bells and whistles, and you’ll pay for features that you don’t need and won’t use.

On the other hand, if you expect to grow as a company, you should invest in CMMS software that’s scalable and can scale over time. In this case, look for software that allows you to easily adjust the number of devices or user subscriptions.

The only way your organization will benefit from a CMMS software solution is if it’s easy enough for everyone to use. Training will be a major factor in the success of implementing your CMMS software, so consider the support available to you from the software company and how you can train your workforce to get your CMMS software solution running.

You need to know more about the technology associated with the CMMS software before making your selection. As technology advances and changes rapidly, your CMMS software will need to be adaptable and flexible to keep up.

Cloud-based CMMS software benefits organizations that need immediate access to information and reports from anywhere, anytime. CMMS software available via a mobile app helps technicians submit work orders and scan durable asset tags from anywhere in the field or on the floor. A Go for a CMMS software solution that features an application programming interface (API) that synchronizes data from various devices, scanners, computers, and more.

In the next section, we’ll review a step-by-step process for successful CMMS implementation. However, before we discuss how to implement a CMMS successfully, it’s important to understand the most common reasons CMMS implementations fail.

Computerized Maintenance Management Systems (CMMS) implementations can fail for various reasons, often due to issues related to planning, user adoption, and management. Here are some of the top reasons why CMMS implementations might not succeed:

Successful CMMS implementation is a major component of your overall preventive maintenance program. Follow these essential steps to ensure a successful implementation and smooth rollout.

A computerized maintenance management system will make your organization more efficient, but only with proper use. A CMMS is a tool, and like any business tool, it’s your job to fashion this solution so it solves your most critical business needs. Follow these best practices to get more ROI from your investment in a CMMS.

It’s difficult to escape the vicious cycle of reactive maintenance (also known as corrective maintenance), but this approach is both more resource-intensive and expensive. With a CMMS, it’s much easier for organizations to take a proactive approach to maintenance, either through preventive maintenance or predictive maintenance approaches.

The future of CMMS lies in leveraging both preventive and predictive maintenance techniques to decrease unplanned downtime, extend asset lifespans, and enhance safety.

Predictive systems require a lot of historical data to draw conclusions. They tend to be more expensive, so many organizations often go with preventive CMMS instead.

The CMMS calculates which hardware needs maintenance and when, routing your teams to optimize equipment performance before there’s an issue. This setup won’t prevent all unplanned downtime, but it will significantly reduce the chances of unexpected failure—and the $260,000-an-hour price tag that comes with it.

Asset tags are an essential tool for bridging the gap between CMMS software and your equipment. Identifying and tagging assets, including meters, stored maintenance items, and stock locations, creates important information for the maintenance department and allows your maintenance team to carry out their important duties seamlessly.

With good planning, identifying key assets and applying asset tags is quick and efficient, providing a framework through which your organization can effectively manage its materials, equipment, and other assets.

However, disorganized or inconsistent asset tagging procedures will hurt your progress. Companies using CMMS solutions should establish standards for asset tag numbers and associated sequential item numbers for CMMS data.

It’s important to define maintenance standards and verify that your team follows these standards. Implementing standard practices, documentation procedures, and protocols ensures that the data managed within the CMMS is accurate and up-to-date.

Not all CMMS include these technologies just yet, but some solutions include artificial intelligence (AI), the Internet of Things (IoT), and integrations. AI and IoT automate maintenance planning and enable smart devices to self-monitor and report in real time, preventing unexpected failures.

AI can even use IoT data to generate incredibly accurate performance and maintenance reports, making predictive maintenance a reality for your organization.

Integration is also a best practice for computerized maintenance management systems. The more your solutions integrate with each other, the fewer platforms you have to consult to perform maintenance.

For example, asset performance management (APM) is a robust solution that combines the maintenance scheduling of a CMMS with the asset tracking and management capabilities of enterprise asset management and IoT. This approach enables real-time tracking of asset performance, anticipating potential faults and preventing them before they occur.

This is just one of the many ways your systems can integrate and create a more cohesive maintenance strategy with little human intervention.

Manual data collection can be difficult and time-consuming. Not only does this give employees a negative experience, but it also leads to more errors. Set up your CMMS to be as user-friendly as possible to speed up maintenance tasks and encourage organization-wide adoption.

For example, portable handheld barcode scanners are more efficient than manual data entry. These scanners, paired with proper asset identification tags, make it easy to enter data, update information, and record maintenance procedures, parts orders, and other information with minimal data entry errors.

It’s also helpful to choose a mobile-first CMMS. Some solutions even allow employees to use their personal devices through the use of a CMMS app, significantly reducing technology costs. These apps also support offline access, photo attachments, voice-to-text notes, and push notifications for new work orders. These features simplify the maintenance process, empowering workers to do better work in less time.

Thanks to barcode scanning, automation, and AI, CMMS data today is cleaner and more actionable than ever before. While some CMMS solutions will automatically generate conclusions based on your data, others require you to comb through the data to find actionable information.

Analysis is the purpose of data collection, so regularly review your CMMS data for helpful insights. Look at costs per machine, maintenance timelines, and downtime to better understand ROI and spot opportunities for improvement. Take advantage of these opportunities to see even more value from your investment in a CMMS.

A computerized maintenance management system helps organizations embrace a more efficient paradigm for maintenance management. By automating critical maintenance tasks, optimizing asset utilization, and enhancing operational efficiencies, a CMMS not only helps in significantly reducing maintenance costs but also in minimizing downtime and extending asset life spans.

The strategic implementation of a CMMS enables businesses to harness data-driven insights for improved decision-making, which is crucial in today’s fast-paced and increasingly complex operational environments.

For a deeper dive into maintenance management, check out The Ultimate Guide to Maintenance Management.

Manufacturing, healthcare, energy, and facilities management are among the industries that benefit most from a CMMS. These industries typically manage a large number of physical assets and equipment, which require regular maintenance and monitoring to ensure operational efficiency and safety.

A CMMS supports regulatory compliance by maintaining detailed records of maintenance activities, safety checks, and repairs. This documentation is crucial for adhering to industry regulations and standards, and it can be easily accessed during audits to demonstrate compliance.

The costs of implementing a CMMS vary depending on factors such as your organization’s size, the complexity of the assets, and the specific features required. Generally, costs include software licensing or subscription fees, initial setup and customization, hardware if necessary, and ongoing training and support.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any asset management or tracking system implementation.