10 Great Warehouse Organization Charts and Layout Templates

Organizing a warehouse properly can make or break the efficiency of your operations. That means not only the layout of the physical warehouse space, but also a properly configured process flow that clearly defines the necessary steps in receiving, inventory management and shipping, among others.

An optimized physical layout, coupled with a robust warehouse barcode label and signage system, is the foundation of an efficient warehouse operation. But how can you best optimize your layout?

We’ve rounded up 10 valuable warehouse organization charts that represent efficient, proven models that work for many of today’s busy warehouses.

SmartDraw provides three example warehouse layout charts you can customize to meet your facility’s needs.

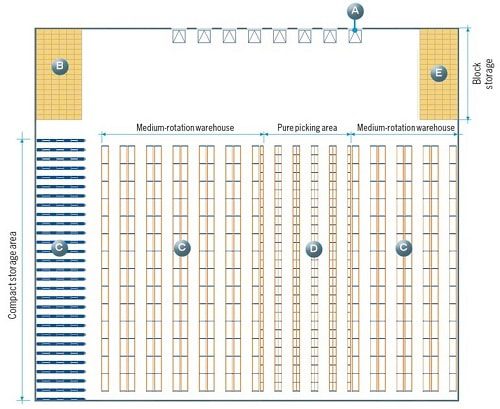

Get It: Warehouse Layout Plan

This example includes block storage areas, compact storage areas, and loading and unloading areas. The layout in this chart is organized in an efficient row system for rack storage, divided into three sections: two medium-rotation warehouse areas on either side of a central pure picking area.

Get It: Warehouse Layout Design

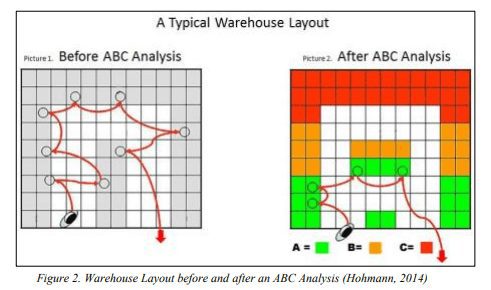

This warehouse organization chart is sourced from the Bachelor’s thesis of Kyle T. Bentz. It illustrates a typical warehouse layout both before and after an ABC analysis, demonstrating the benefits gained from performing an analysis to optimize your facility’s storage.

The red line illustrates the path a worker takes to pick an order. In the second layout, inventory is organized by picking frequency and sales revenue, drastically simplifying and shortening the picking process.

Get It: Warehouse Layout Before & After ABC Analysis

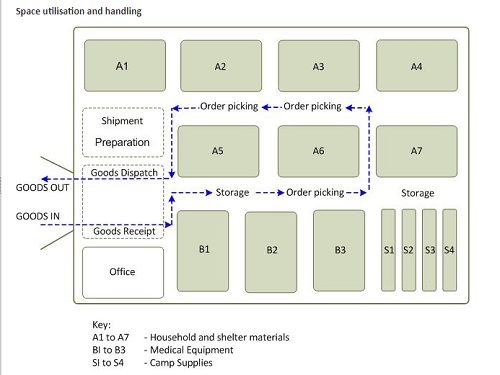

This warehouse organization chart from Logcluster illustrates the flow of goods as they enter and exit the facility. The layout is grouped by inventory type, with clusters of racks in distinct areas of the building.

The racks are organized in a logical way to ensure that the traffic pattern takes workers through each section with easy access to all racks to allow for streamlined order picking.

Get It: Warehouse Organization Chart

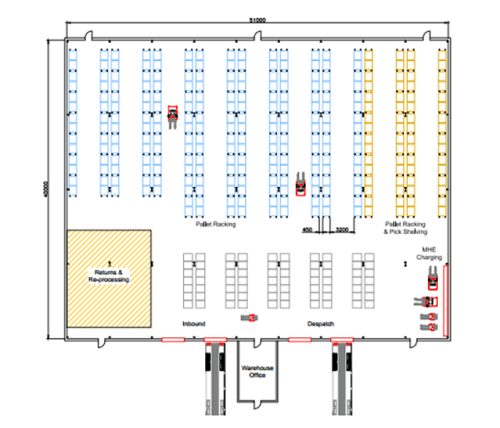

Go Supply Chain is a consultancy that offers warehouse layout optimization services. The example layout provided here includes inbound and dispatch areas, a section dedicated to pallet racking and pick shelving, a large space dedicated to standard pallet racking, an area for MHE charging, and a returns and reprocessing area.

The warehouse office does not take up valuable floor space; instead, it’s positioned as an extension of the main warehouse, conveniently located between inbound and dispatch.

Get It: Warehouse Organization Chart

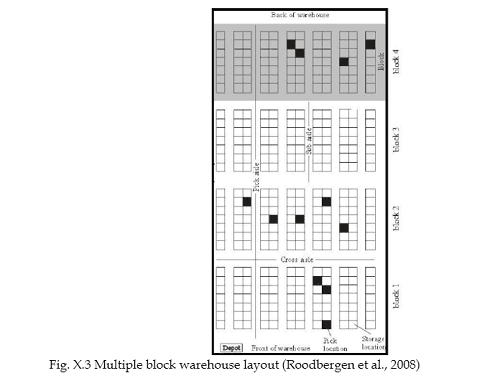

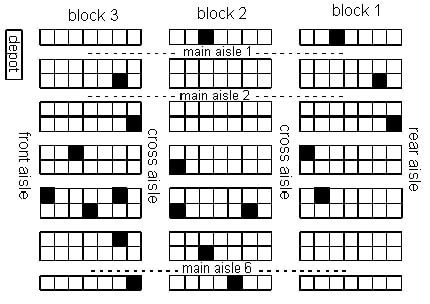

This warehouse organization chart appears in a research paper by Goran Dukic and Opetuk Tihomir, obtained from ResearchGate. It represents a multiple block warehouse layout, a shift from the traditional row-based design achieved by adding one or more cross-aisles. The addition of cross-aisles can improve total travel distances. The authors also note that through careful analysis, it’s even possible to determine the ideal number of cross-aisles that will offer the biggest benefit to a warehouse’s efficiency.

Get It: Multiple Block Warehouse Layout

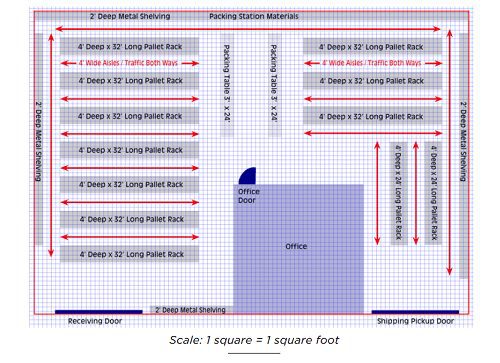

Fit Small Business outlines the process of creating an effective warehouse layout schematic, including this example layout illustration.

In this schematic, deep metal shelving and storage areas for packing materials are situated along the perimeter of the facility. Deep, long pallet racks make up the majority of floor storage space, complete with wide aisles to allow for optimal traffic flow in both directions.

Get It: Warehouse Layout Schematic

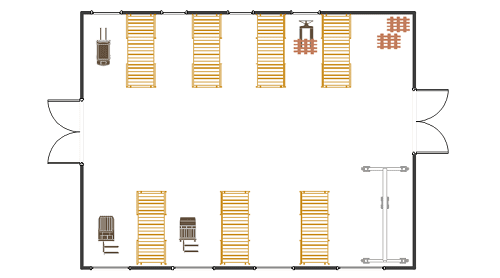

This warehouse layout takes a different approach to rack configuration, with a wide center aisle with rows of perpendicular racks on either side. This leaves ample space for MHE and foot traffic, allowing for efficient traffic flows and optimized picking and stocking processes.

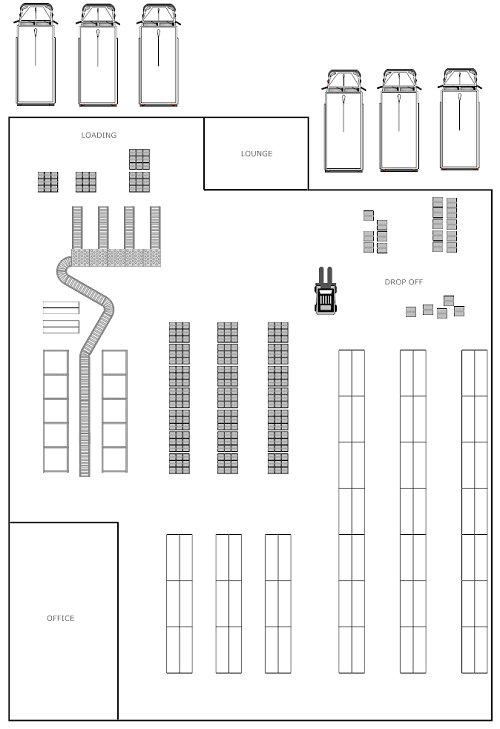

This warehouse layout from ConceptDraw incorporates a conveyor belt into the design. So if your warehouse is embracing technology to streamline processes, this is a good example you can build on to determine how to best incorporate major, space-consuming features in your building’s layout.

Get It: Warehouse Layout Floor Plan

This simple block-style layout from AdaptALift incorporates three blocks, including three main aisles (1, 2, and 6) and two cross-aisles, as well as a front aisle and rear aisle to allow ample space for traffic flow in both directions.

Get It: Warehouse Aisle Layout

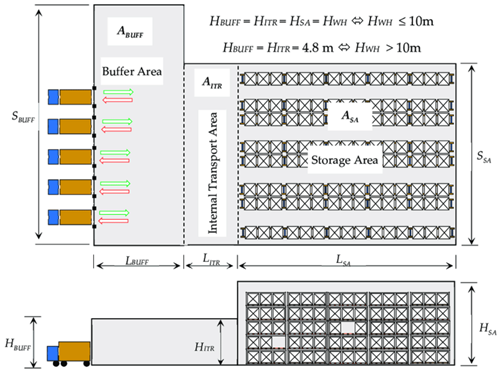

Research Gate has a schematic warehouse organization chart (via creative commons) that seeks to optimizes energy consumption as an essential component of green warehousing and a means to reduce the carbon footprint of supply chains.

Get It: Schematic Warehouse Layout

There is no single best way to design a warehouse layout, but there are some best practices that can help to ensure that your warehouse runs as efficiently as possible. Eliminating obstacles and unnecessary traffic congestion while storing inventory strategically can result in dramatic reductions in picking and stocking time, lowering overall operation costs.

Use these warehouse organization charts as inspiration but tap into your organization’s research and analysis to determine the optimal layout for your facility.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any warehouse management system implementation.