What is Supply Chain Management (SCM)? How Does It Work?

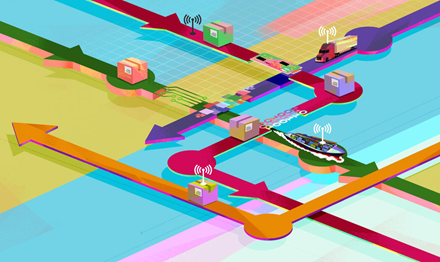

In today’s interconnected global economy, supply chain management has become a critical factor in the success of businesses across industries. From small startups to multinational corporations, organizations are increasingly recognizing the importance of efficiently managing the flow of goods, information, and finances from suppliers to end consumers.

Supply chain management is no longer just about moving products from point A to point B; it’s a complex, strategic discipline that can significantly impact a company’s bottom line, customer satisfaction, and competitive advantage.

Let’s dive into the world of supply chain management, exploring key components, challenges, and the transformative role of technology in shaping modern supply chains.

Supply chain management (SCM) is the oversight and facilitation of the people, processes, information, and technologies involved in the flow of goods and services from manufacturers and producers to customers and end users.

Supply chain management has become “a highly sophisticated, technology-dependent, and collaborative discipline that combines the business functions of purchasing, operations, inventory management and warehousing, customer service, and logistics (source).”

The goal of supply chain management is to streamline these activities to ensure optimal efficiency and cost-effectiveness from start to finish, encompassing everything from production to product development, as well as the systems and processes utilized to direct these activities.

Supply chain management professionals focus on managing the flow of goods, information, and revenue while surpassing customer expectations and keeping costs to an absolute minimum.

Ultimately, supply chain management aims to boost revenue and cut costs while having a positive impact on the company’s bottom line. Now that we’ve established a broader understanding of supply chain management – the three levels of SCM and five core process flows – it’s easier to understand how the many facets of supply chain management work together on a more granular level.

Here’s a look at some of the core elements of supply chain management that exist below the macro-level concepts discussed previously.

In order to accurately plan and manage inventory, companies must monitor activity, identify trends, and make predictions to forecast future demand. This enables organizations to better plan and configure the flow of manufacturing processes to ensure that these demands are met.

Also known as consumption management or strategic spend management, demand management enables organizations to address external spending, arrange and manage purchase orders, and eliminate waste.

Demand management can help companies answer pertinent questions such as:

As modern supply chains become increasingly complex, there’s a pressing need for streamlined communication and collaboration. It’s worth noting that in some schools of thought, communication and collaboration are considered as distinct elements within supply chain management.

Effective communication, both internally and externally, improves visibility throughout the supply chain, which can eliminate mistakes, enhance relationships with vendors and suppliers, and ensure that all people involved in the supply chain from start to finish are aware of their responsibilities.

In short, communication is an important factor in the people element, making sure that everyone has the information they need to do their jobs better and on time. Today, communication is largely fueled by technology.

While communication refers primarily to the sharing of information, you can think of collaboration as the relationships that exist (and must be nurtured) between organizations and their vendors and suppliers, end consumers, and any other partners or third parties. Strengthened relationships with suppliers can enable organizations to obtain discounts, resulting in lower costs, and it also enhances stability and flexibility.

The two concepts are distinct, but closely related, as communication is imperative for effective collaboration.

An individualistic approach to supply chain management – one in which individual workers and departments are treated as stand-alone, independent entities – has become ineffective in modern supply chain management. It’s impossible to facilitate the continuous, streamlined flow of supplies, goods, and processes throughout the complex supply chain when functions, people, and departments exist in silos.

Business process integration seeks to eliminate those silos, ultimately considering the various workers, departments, and functions as a cohesive entity. Processes and functions in the supply chain are often interwoven, with most processes having an impact (or being impacted by) other functions and processes.

Understanding how these processes work and relate to one another allows organizations to identify processes most suitable for integration.

Business process integration can involve several or all of a multitude of processes, such as:

Like communication and collaboration, business process integration is fueled by technology in many cases. Enterprise application integration (EAI) technology is one such solution, while many modern supply chain management solutions also aim to integrate core SCM processes to streamline real-time information sharing.

However, integrating business processes is typically a gradual process, with a focus on integrating processes with the greatest ROI potential first, often starting with internal processes and incrementally working outward through the rest of the supply chain.

A supply chain is “the connected network of individuals, organizations, resources, activities and technologies involved in the manufacture and sale of a product or service,” explains Investopedia. “A supply chain starts with the delivery of raw material from a supplier to a manufacturer, and ends with the delivery of the finished product or service to the end consumer.”

The role of supply chain management is to oversee each touch point throughout this journey, from product development to the final sale to an end consumer. That means there are many junctures throughout the supply chain where organizations can add value through greater efficiency or lose value when expenses are increased without other factors that mitigate those increased costs.

Supply chain management, therefore, involves a variety of functions, processes, and activities. All of these things fall into one of three levels of supply chain management. Understanding these three levels makes it easier to grasp the scope of supply chain management as a whole.

Strategic planning decisions, often made by upper management, are typically those that affect the organization as a whole rather than individual departments or functions, and they often involve long-term planning. For instance, the decision to open a new manufacturing facility or warehouse is a strategic decision, as well as the decision to explore new markets or develop new product lines.

Strategic planning decisions are often the first step in developing and defining processes. Examples include how inventory and products are managed throughout the lifecycle, investments in IT solutions that can improve efficiency and/or accuracy, or choosing a site for a new business facility.

Tactical management decisions are where processes are actually defined, and these decisions play an important role in both minimizing risks and controlling costs. This level emphasizes consumer demand and aims to achieve the best value.

Examples include obtaining procurement contracts for materials and services, developing production schedules, establishing guidelines for meeting regulatory standards, and warehousing and logistics decisions.

Operational decisions should be made only within the context of strategic and tactical decisions that have already been established. Many businesses make the mistake of starting with operational planning without first addressing strategy and tactical planning and decision-making needs.

The decisions made at the operational level impact the day-to-day operations of a business unit, department, or individual, and are designed to ensure the maximum cost benefit and overall efficiency of the supply chain – in short, the activities carried out and decisions made at the operational level are what keep the supply chain active.

Operational processes include managing the flow of products and materials (both incoming and outgoing), managing inventory, overseeing production operations, and daily and weekly forecasting to inform decisions that enable the company to meet demands.

When planning and decision-making is conducted efficiently, with operational decisions made with an awareness of the broader strategic and tactical decisions, the supply chain functions more efficiently as a whole.

Decisions made at any level described above are concerned in some way with one or more of five primary process flows that exist in supply chain management. Each of these core process flows may be comprised of hundreds – easily thousands – of macro and micro processes that take place to keep the supply chain functioning.

The five primary process flows include the following.

Of course, the ultimate goal of supply chain management is to ensure the efficient flow of products through the life cycle, from production to delivery to the customer or end user. Supply chain management must also ensure a smooth flow of products in the reverse, facilitating a streamlined process for customers to return products to the company, as well as processes and procedures for restocking, refurbishing, or disposing of returned products.

Without real-time information, errors and delays are impossible to avoid throughout the supply chain. Thus, supply chain management must ensure a seamless flow of information internally among departments as well as among the company and its vendors, suppliers, third-party logistics organizations, and customers.

Product inventory, supply inventory, orders placed, order status, returns received, refunds processed, and delivery information are just a few examples of real-time information imperative to effective supply chain operations.

Money is to the supply chain as fuel is to automobiles; without it, the supply chain comes to a screeching halt. Pricing, credit terms and contracts, payment terms, and other financial exchanges must all function smoothly to avoid disruptions in the supply chain.

Value-creating processes exist throughout the supply chain, with the ultimate goal of adding value to benefit the end consumer. These processes even exist after production, such as in retail settings where the products are eventually sold to the end user.

In this case, the value add is that the retailer is making the product available and accessible in a convenient way for the consumer. This concept is also known as a “value chain,” as the product gains value as it moves through each point throughout the supply chain.

The value chain is another area where companies can gain a competitive advantage. Costs, revenues, and values are assigned at each stage, and companies can gain a competitive edge by controlling or regulating cost drivers, reconfiguring the value chain, or through other means.

Risks are prevalent in the supply chain. Risks may be disruptions, price volatility, issues with product or service quality, physical infrastructure deficiencies, natural disasters, or even reputation management concerns, such as reputation damage resulting from a cyberattack that impacts vendors and suppliers or end customers.

Risks may also be financial in nature, such as cash flow constraints, delayed cash payments, or inventory financing issues. Risks may be internal or external, and the level or risk can increase or decrease with fluctuations in any of the other four process flows.

External risks can occur from the upstream or the downstream of the supply chain, such as demand risks resulting from unpredictable consumer demand or inaccurate demand forecasting, or supply risks resulting from disruptions in the flow of goods to or from external partners, suppliers, or vendors.

Internal risks result from events that are within the organization’s control, such as manufacturing risks arising from disruptions in production, planning or control risks resulting from poor assessment and planning, or mitigation and contingency risks resulting from a failure to establish contingencies.

When these flows are properly integrated, better collaboration and coordination can exist. Increased visibility and real-time information sharing aligns supply chain partners and facilitates greater flexibility to adapt to external factors such as unexpected shifts in demand, increased competition, regulatory changes, and other factors.

Obviously, with so many moving parts, processes that must work cohesively, relationships to manage, and other factors to consider, supply chain management is an incredibly complex function. Here’s a look at some of the main challenges facing today’s organizations in supply chain management.

Globalization is a broad concept, but within it are several specific challenges in supply chain management. For instance, supply chain management is focused on reducing costs throughout the supply chain, and globalization often leads companies to move manufacturing operations to regions or countries where labor is more affordable, taxes are lower, or raw materials or transportation are more cost-effective.

Often, companies outsource production to several countries for various parts, components, or production phases. The procurement network necessarily expands as a result, which complicates the supply chain, leaving companies to navigate the manufacturing, storage, and logistics across borders.

All of this must occur while maintaining acceptable delivery speed for end customers and maintaining real-time visibility into the complete production cycle.

Another challenge in supply chain management is increased competition. As barriers to entry in many industries are lower today than they were many years ago, it’s easier for new companies to emerge and threaten the market share of established organizations – often because they embrace innovations that enable them to produce the same end result with greater efficiency or at a lower cost.

This challenge isn’t new; in fact, a 2010 survey conducted by McKinsey & Company found that increasing pressure from global competition was a key challenge for many survey respondents, both over the three years prior and looking ahead to the following five years (through 2015).

Competition is always a concern for supply chain organizations. However, companies started looking at competition through a new lens: leveraging effective supply chain management as a means to gaining a competitive advantage.

How can you leverage your supply chain as a competitive advantage? By looking at your supply chain as a value chain and focusing on six core principles, according to Supply & Demand Chain Executive:

Getting distracted by shiny new objects is a prominent challenge across many industries, and supply chain management is no exception. Implementing technology should have a clear benefit to the supply chain, from simplifying processes to improving visibility, enhancing efficiency, or lowering costs. Technology investments should produce ROI, whether directly or indirectly.

That said, the temptation to jump on the latest technology bandwagon is real – often grounded in FOMO (fear of missing out). What happens if your competition invests in the latest technology advancement and you opted out, leaving them with a competitive advantage?

There are many technologies worth investing in to improve supply chain management processes; in fact, certain technologies are essential for effective operations. But investing in the wrong technology can have negative impacts that affect every facet of the organization, down to the bottom line. That’s why investments in technology and other resources require careful consideration and cost-benefit analysis.

As supply chain organizations increasingly rely on technology, such as cloud computing, to streamline business processes, security vulnerabilities become an ever-more prominent threat. Security risks aren’t comprised only of cybersecurity, but also physical security risks, such as cargo theft.

But the size and complexity of modern supply chains make managing security increasingly challenging: products change hands a multitude of times before reaching the end consumer, and often, multiple nations are involved in the process from production to delivery.

There’s a trust factor involved, of course, pointing to the need to carefully and thoroughly vet vendors, suppliers, and other partners. Supply chain security requires a multi-layered approach to create a secure, end-to-end physical chain of custody with clearly defined and enforced protocols, strict adherence to regulatory guidelines and standards, secure facilities and adequate surveillance, and thorough contractual agreements with trusted partners, as well as adequate cybersecurity tools and solutions to protect sensitive information.

Regulatory compliance is another prominent pain point in supply chain management, and globalization makes compliance even more complex. Environmental regulations, global trade rules, product integrity requirements, and other regulatory concerns have a major impact on the supply chain from end-to-end. Effective regulatory compliance means adhering to a variety of guidelines and standards including:

Effective compliance management is a multi-faceted approach that encompasses governance and leadership, risk assessment and due diligence, standards, policies, and procedures, training and communications, employee reporting, testing and monitoring, continuous improvement, and other processes and functions.

As mentioned, technology is imperative for effective supply chain management, but choosing the right technology is paramount. Technology can aid in reducing shipping errors, organize and manage inventory data, monitor shipping and tracking information, and even manage orders with vendors and suppliers, including generating invoices and purchase orders.

As distribution centers have become a more central component in the supply chain, driven by the need to get products to consumers more rapidly than ever before, e-commerce businesses disrupt the retail space, and other disruptions are shifting the flow of goods through the supply chain, technology is essential for managing this increased complexity.

Here’s a look at a few of the core technologies leveraged by modern supply chain organizations, including asset tracking, software, cloud computing and mobility technologies.

Asset tracking has long been a staple in supply chain management, serving as the foundation for the robust tracking and monitoring technologies organizations are leveraging today. It does little good to leverage inventory management technology, for instance, without asset tags, barcode labels, and RFID tags needed to facilitate automatic data capture. For organizations that manage thousands of parts and supplies, or thousands of SKUs or more, manual inventory management is simply not cost-effective, it’s not efficient, and it’s often rife with human errors.

Fortunately, asset tags and barcode labels are no longer merely a barcode printed on a flimsy sticker. Today’s asset tags and tracking labels are robust and durable, and customized to suit the application.

For instance, modern warehouses can be equipped with a variety of warehouse labels, from warehouse floor labels to multi-level rack labels, cold storage labels, and even long-range retro-reflective labels for long-distance scanning. Coupled with indoor and outdoor signage, aisle signs, and dock signs, these solutions provide a complete, customized foundation that fuels efficiency and accuracy throughout the warehouse.

There are myriad software applications used in supply chain management, from data analytics and forecasting tools to customer relationship management software, inventory management software, and more. Supply chain management software is a distinct category with solutions often aiming to combine several of these functions as a single, fully integrated solution.

The most effective supply chain management systems help businesses reduce waste, keep overhead costs at a minimum, and diminish shipping delays. Supply chain management software provides value to companies by providing smooth planning and execution of operations for profitability.

SCMS offers complete visibility across the entire supply chain and allows managers to monitor the status of activities across suppliers, plants, storage facilities, and distribution centers. Effective tracking and management of these related processes and mission-critical activities aids supply chain managers in recognizing inefficiencies and potential issues and correcting them before they grow.

Overall, SCMS helps to improve the entire supply chain network.

Other benefits of supply chain management software include minimizing delays, enhancing collaboration, and reducing costs.

suppliers, distributors, and supply chain managers to know exactly what is happening at all times. SCMS allows participants to dynamically share vital information in real time to ensure supply chains run as efficiently and smoothly as possible.

suppliers, distributors, and supply chain managers to know exactly what is happening at all times. SCMS allows participants to dynamically share vital information in real time to ensure supply chains run as efficiently and smoothly as possible.The supply chain management (SCM) software market is experiencing significant growth and transformation, driven by technological advancements and evolving business needs. Here are some key statistics and trends to take note of:

These insights highlight the dynamic nature of the SCM software market and the critical role of technology in shaping its future.

Overall, there are hundreds of supply chain management software solutions to choose from: Capterra lists more than 250 vendors, while Software Advice lists more than 200 supply chain management software solutions.

As mentioned, SaaS solutions are increasingly popular in supply chain management, due to the growing awareness of the functional benefits of the cloud. In fact, cloud computing is the key factor in the ability to accurately track a product through its entire lifecycle. Other benefits of cloud computing in supply chain management include:

Mobility makes real-time logistics management achievable for today’s organizations, boosting communications within transportation networks and enhancing the accuracy of productivity and efficiency metrics, while also eliminating many previously manual tasks, such as the need to radio or use onboard terminals to communicate deliveries, pickups, or adjustments.

Manufacturers are looking at ways to embrace the use of mobile devices in the workplace, such as to facilitate real-time status alerts on employee locations, using apps to track truck locations, and more.

“Mobility is another tremendous tool providing applications that improve the quality of life by offering access and connectivity,” according to Bryan Ball in a white paper by Aberdeen Group. “In supply chains, it has enabled real-time capture of all transactions to paint an accurate picture of inventory positions, eliminating reviews and accelerating processes.”

Mobility can help to pinpoint productivity gaps, allow for the use of trucking apps for logistics management, and even help to enable the real-time flow of information to customers.

Many other innovations are emerging as potential disruptors in supply chain management, from the Internet of Things (IoT) to robotics, self-driving vehicles, drones (for delivery), and more. This article from Inbound Logistics provides a solid overview of these and other technologies that are disrupting the supply chain.

All of these factors considered, it can be difficult to imagine how the many elements of supply chain management can work together as a cohesive, collaborative operation. Incorporating these best practices enables the supply chain to function like the well-oiled machine it should.

Supply chain management is key to managing the flow of products, information, and finances. Effective supply chain management improves product quality and order turn-around times.

Supply chain management professionals also ensure streamlined operations that keep costs to a minimum. Top supply chain managers mitigate risks and give businesses a competitive edge in the marketplace by utilizing supply chain management software.

A successful SCM strategy includes several key components:

Each component must be effectively managed and integrated to ensure the smooth flow of goods and services from suppliers to customers.

Supply chain management is crucial because it directly affects a company’s ability to meet customer demands, manage costs, and maintain competitive advantage. Effective SCM ensures that products are delivered efficiently and cost-effectively, enhances customer satisfaction, and enables companies to respond swiftly to market changes and disruptions.

By optimizing the flow of goods and information, SCM can significantly improve a company’s operational efficiency and profitability

Technology plays a crucial role in enhancing supply chain management by providing tools for better data analytics, real-time tracking, and automation. Technologies like AI, IoT, and blockchain help in improving visibility, forecasting, and decision-making processes, leading to more efficient and resilient supply chains

Organizations face numerous challenges in SCM, including cost management, supply chain disruptions, sustainability concerns, and the need for digital transformation. These challenges require proactive strategies and the adoption of innovative technologies to optimize operations and maintain competitiveness

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›Enter your information and get a free checklist of the top questions to answer and tips to plan a successful asset tagging project for any warehouse management system implementation.