RFID Tags on Metal: Everything You Need to Know

If you’re considering adopting an asset tracking technology to streamline equipment tracking and maintenance or enhance the security of your assets, RFID is one solution you may have encountered. But if you want to use RFID tags on metal, there are a few important things to know, such as:

Radio-frequency identification (RFID) technology dates back to the early 1980s, but did not become widely used until the early 2000s. RFID technology has primarily been used to facilitate near-field communication (NFC) with various scanning devices, such as point-of-sale systems.

In recent years, many entities have explored RFID tags as a means of tracking products across the supply chain. While the functionality of RFID technology is well documented, some manufacturers question the product’s viability when affixed to metal.

If your organization has considered incorporating RFID into its asset tracking and traceability initiative, this guide will help you determine whether it is the right move. We cover the basics of RFIDs, address security concerns, and outline some potential benefits and shortcomings so that you can make an informed decision.

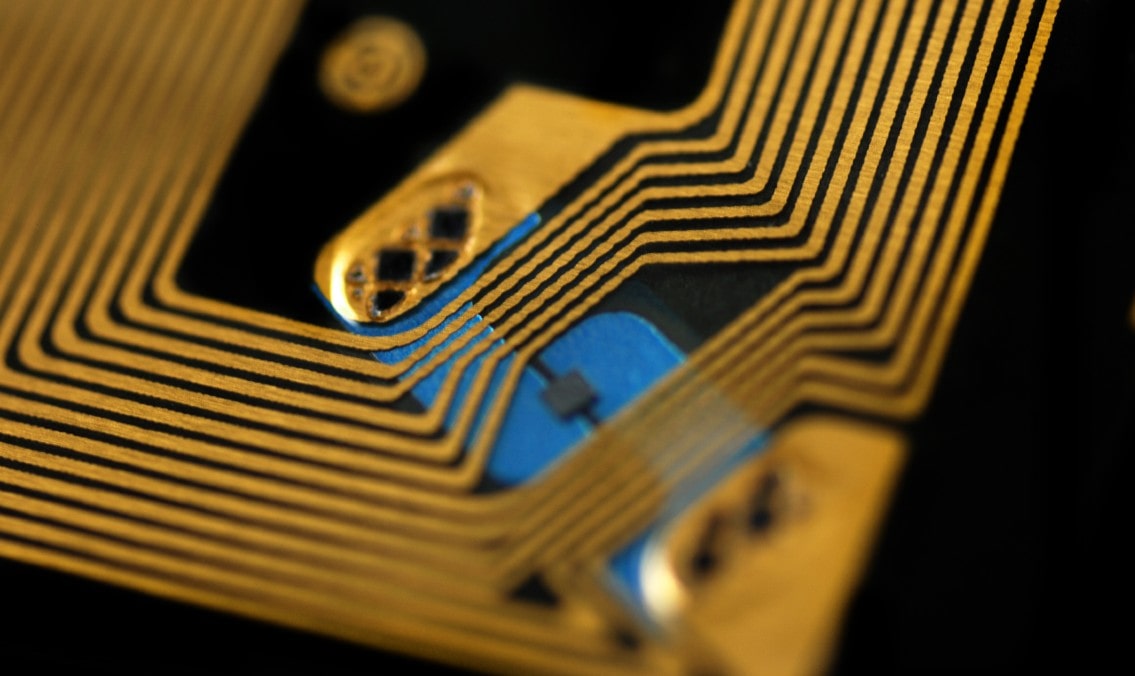

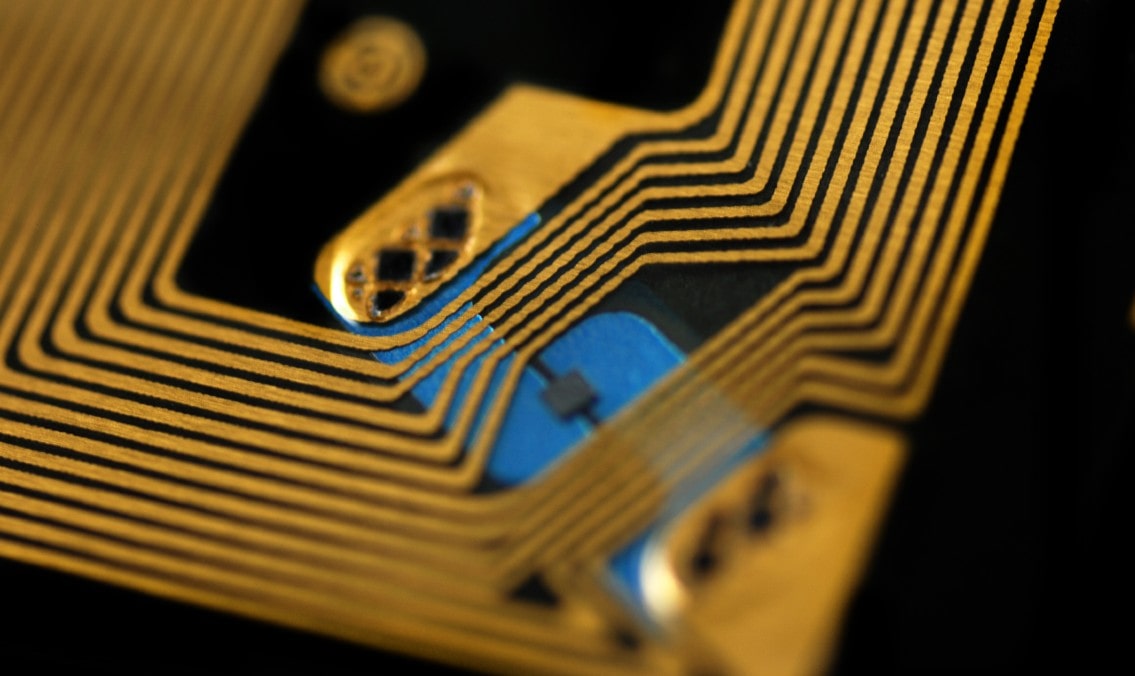

RFID tags contain information that can be read and captured via radio waves. The tags contain both a receiver and transmitter so that they can communicate with scanning devices. They also have an antenna and a microchip. Most importantly, RFID tags contain a unique serial number for the product they are affixed to.

There are two broad categories of RFID tags: passive tags, and active or battery-powered tags. The latter are slightly bulkier because they contain batteries, which enable them to relay information actively. Passive RFIDs send information by leveraging the radio energy of tag readers.

Yes, RFIDs can be fastened to metal objects. However, most methods of affixing RFID tags to metal have significant drawbacks.

The most common method involves the use of a very strong adhesive. Alternatively, your business can place the RFID into a small protective sleeve and secure the sleeve using rivets.

The primary concern when using adhesive is that it can negatively impact the finish of the product. This can be particularly problematic when using RFIDs to track home goods and other materials where consumers are focused on both aesthetics and function.

Attaching the RFID with rivets can be a good option because it causes minimal damage to the finished surface of a product. The downside is that these RFID containers have a larger footprint and are more likely to be exposed to abrasive forces during transport.

RFIDs are designed to be easy to program in order to encourage their adaptation. The downside is that this attribute also makes it easy to duplicate or counterfeit RFID tags, a significant problem for military asset tracking and in other industries where asset security and integrity is paramount.

In order to combat counterfeiting, some companies have produced encrypted RFID tags and scanning devices. As with any improvements, this involves a trade-off. Namely, RFID equipment that supports encryption can be cost-prohibitive, especially when compared to many other tracking and tracing solutions.

Provided that your organization invests in the more costly encryptable RFID equipment, this technology can be quite secure. Unfortunately, your organization will still need to contend with durability concerns, as RFID tags have been subjected to limited third-party testing.

Naturally, any solution that is affixed to metal products or materials needs to exhibit exceptional durability. Therefore, your organization should consider other options when implementing an identification system for metal products.

s you can see, RFID tags can be mounted to metal products. They are also capable of providing detailed product data, including the serial number, manufacture date, and so on.

Unfortunately, these positive attributes are offset by concerns about the durability and security of RFID tags. In order to address these concerns, your organization would need to invest in more robust, encryptable RFID technology. Ultimately, this can make your product identification program too costly.

The good news is that there are several solutions that outperform RFID technology across virtually every relevant metric. The most well-known of these is Metalphoto®, a specialized kind of anodized aluminum that is photosensitive. Metalphoto has a variety of government, industrial, and defense certifications and specifications and has been used in the field for over 50 years.

Some of the benefits of Metalphoto include:

Additionally, Metalphoto tags can be scanned with standard barcode readers. This helps further reduce costs while simultaneously making it easier to adopt this time-tested technology. For years, Metalphoto identification tags have been trusted by the U.S. military, as well as top companies like Boeing and Caterpillar.

If you need a safe, cost-effective, and secure way of identifying your metal products and goods, Metalphoto tags are the answer. To obtain a detailed quote for Metalphoto identification tags, submit your request to Camcode today.

While RFID tags can be attached to metal surfaces, they’re not ideal when aesthetics matter. That’s because the adhesive can damage the metal’s finish and attaching an RFID tag with rivets requires a protective sleeve that can be damaged in transport. RFID hasn’t undergone significant third-party testing assessing its durability in various environments, and there are also counterfeiting and cost concerns. Metalphoto asset tags are an ideal alternative with proven durability and anti-counterfeiting properties. Additionally, Metalphoto asset tags are easily affixed to metal and come in a variety of configurations so they can actually enhance the aesthetic appeal of your assets — and they’re also far more cost-effective than RFID.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›