Durable UID Labels for MIL-STD-130

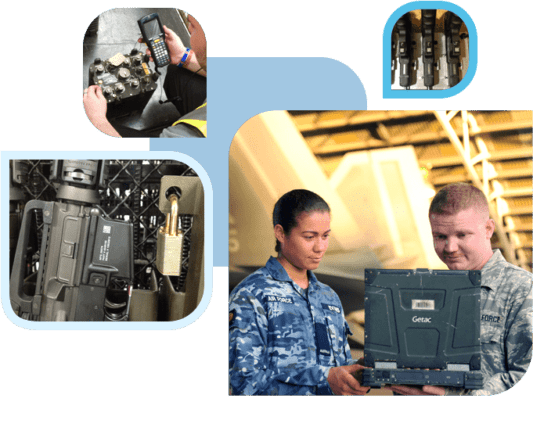

Track and maintain your assets to keep operations running smoothly.

Labels That Meet Defense Standards and Last the Life of Your Assets

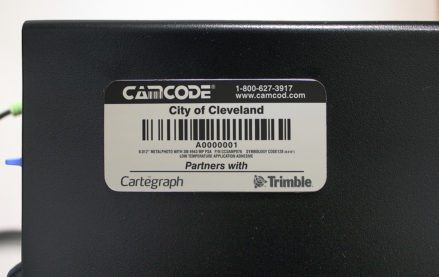

Camcode offers more permanent and durable label solutions for UID applications than anyone. Our UID label materials are the most widely specified in the defense industry, and are continually trusted to provide permanent and durable unique identification that lasts a lifetime. Your product choices include a wide variety of UID labels, such as Metalphoto® anodized photosensitized aluminum, Teflon™ UID labels, CARC paint UID labels, Sandshield protective covers, premium polyester UID labels and more. Before producing your UID label or UID tag order, we’ll send you a PDF proof of your exact design and data string to ensure it’s correct. Every order ships with a certification that the format and quality meet the rules of MIL-STD-130 or STANAG 2290.

UID Labels for Any Application

Whatever your application, our labels help solve your specific defense asset management challenges. Find the asset tags specifically designed for UID organization or project.

Laser Markable Label Blanks To Create On-Site, On-Demand UID Labels

Making asset labels on-site can be favorable to buying labels. When lead times are short or you need access to real–time production of labels, on-site printing is the solution. And when permanent, durable labels are required, laser marking on metal is the solution of choice.

Get a Free UID Label Evaluation Kit

Request a free unique identification label sample kit today and we will send you a kit to test our extremely durable labels in your own operating environment.

UID Labelling Services for MIL-STD-130

We can also help with your UID service needs. From on-site UID label installation to IUID registration, Camcode is your single source for all your UID, Mil-Std-130 and asset traceability solutions.

Why do you need UID labels?

UID labels are part of a robust and mandated program for the tracking of U.S. Department of Defense (DoD) designated assets throughout the world.

Remain Compliant

Enable Traceability

Ensure Performance

Maintain Durability

Common Use Cases For UID Labels

Much of the challenge in choosing the right UID label for each application involves matching the substrate with the environmental conditions, required level of adhesion on the surface material, and the intended use of the item.

Hard to Bond Surfaces

Curved or Uneven Surfaces

Tactical Equipment

Harsh Environments

“All of our contacts with Camcode were essential in understanding UID.”

“We were quickly able to make the right decisions to lay down a failure-free UID foundation.”

“We recommend Camcode to our NATO colleagues.”

“Whenever we can, we recommend Camcode to our NATO colleagues as a solid, reliable and understanding UID business partner.”

Discover Insights into UID Identification & Tracking

Explore our case studies, blog, buyer’s guides, specification sheets and more — and start learning more about the complex world of asset tracking. View All Resources ›

Frequently Asked Questions About UID Labels

A UID label (unique identification label) is a type of asset label required by MIL-STD-130 to comply with U.S. Department of Defense standards. UID labeling is used for asset traceability by the U.S. government. UID labels must contain specified information in a readable format on a label constructed of durable materials that can withstand the expected conditions the asset will be exposed to.

Metalphoto® photosensitive anodized aluminum is the most widely specified UID label material.

Companies that manufacture and send assets to the U.S. government are required to comply with the UID labeling requirements specified in MIL-STD-130. Companies that manufacture assets that cost $5,000 or more, assets considered mission-critical, or controlled inventory use UID labeling to ensure their products meet the government’s required marking specifications.

The U.S. Department of Defense and associated government entities also use UID to participate in the DoD’s asset traceability program.

UID for DoD is the unique identification required by the Department of Defense for all critical assets. The UID in this context may be used to refer to the U.S. Department of Defense’s asset traceability program, or it may also be used to describe the specific identification markings required for DoD assets.

UID stands for Unique Identification, while IUID stands for Item Unique Identification. Both terms refer to the asset labeling specifications required by the U.S. Department of Defense for critical assets. IUID is most commonly used when referring to the ‘IUID Registry,’ which is the database that stores all UID asset information.

A UID barcode is a marking that complies with the requirements of MIL-STD-130. These requirements include the recommended barcode symbology (2D data matrix format) and the label format (which includes the part number, barcode, and a unique serial number assigned by the supplier, or the lot/batch number, part number, and the asset’s original serial number).

The UID label must be constructed with a substrate material that meets durability requirements. Metalphoto® photosensitive anodized aluminum is the most-specified material by the U.S. DoD and meets the requirements of MIL-STD-130.

Keep Operations Efficient with Barcode Asset Tracking Tags

If you’re having trouble finding the ideal tracking solution for your project or organization, build it with Camcode. Talk to our team today.