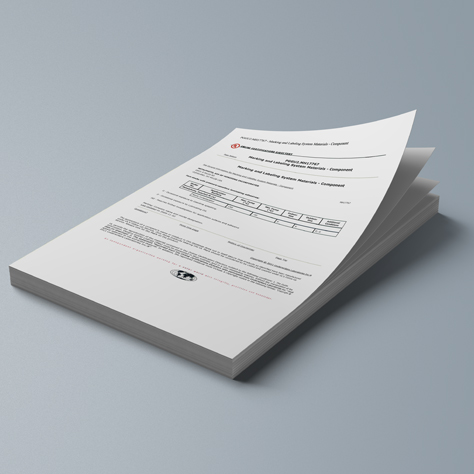

Warehouse Rack Labels

Customized identification and tracking labels for every warehouse environment and application.

Build a Better Warehouse Labeling Solution With Bar Code Rack Labels

Warehouse rack labels are a versatile solution that is not only cost-effective to implement, but result in substantial savings in both time and money by streamlining processes and reducing workforce demands. By simplifying the process for stocking and retrieving products, as well as maintaining tighter inventory controls, your warehouse runs like a well-oiled machine.

A Variety of Warehouse Rack Label Solutions to Meet Modern Warehousing Requirements

Camcode offers a multitude of warehouse rack labels designed to suit the needs of various applications. For instance, magnetic rack labels can be easily relocated without leaving sticky residue behind, also eliminating the need to replace labels for seasonal items or other products that may be relocated throughout the facility.

Multi-level rack labels eliminate confusion for workers and reduce the need for long-range scanners, saving time and reducing hardware requirements. These and other warehouse rack label options from Camcode are designed with the needs of modern warehousing in mind, with the durability required to stand up to the typical wear and tear common in warehouse applications.

With a multiple of options designed for use in less-than-ideal environments, our warehouse rack labels will last for years of typical use. That means you won’t be re-investing in label replacements due to premature breakdown or fading. For example, Camcode’s cold storage rack labels and cold storage rack placards, designed for use in environments down to -20°F and -40°F, respectively, provide an ideal warehouse rack labeling solution for warehouses dealing with perishables or frozen goods.

Get a Free Warehouse Label and Sign Evaluation Kit

Request a free warehouse label and sign sample kit today and we will send you a kit to test our durable labels and signs in your own warehouse environment.

Get the Right Labels for Your Warehouse

Camcode has warehouse rack labels for every application. Our polyester warehouse rack labels offer the durability demanded in many applications. Magnetic warehouse rack labels are perfect for easy relocating. Multi-level bar code labels can eliminate the need for long range scanning and are designed to eliminate the confusion of which rack to scan.

We design each rack label for your application. By considering your inventory system, scanner type, scanning distance and angle, and mounting method, we assure that you receive the highest value warehouse rack labeling solution.

Better Inventory Control and Data Management with Camcode’s Warehouse Rack Labeling Solutions

Labeling solutions like magnetic rack labels and cold storage rack labels provide value beyond merely making it easier to locate the proper shelves or products. Better inventory management is a common goal among warehouse leaders, as there’s a direct correlation between effective inventory control processes and the bottom line. When you gain more visibility into data, you can optimize the supply chain to maximize the use of every inch of space in your facility.

Warehouse rack labels are the key to capturing valuable business data that drives decision-making and boosts the bottom line. Combined with the right software application, your data can provide clues to optimizing warehouse layout to make more efficient use of space and precisely configuring ordering and shipment schedules to reduce waste and maintain the optimal flow of inventory both in and out of your facility.

Improve Staff Efficiency with Warehouse Rack Labels

In addition to improving the speed at which staff are able to locate the proper shelves or inventory to prepare shipments or re-stock products, warehouse rack labels dramatically improve record-keeping accuracy. With the ability to scan a rack label to document the date, time, and location of an activity, warehouse rack labels virtually eliminate the errors that commonly result from manual record-keeping processes.

Armed with accurate data, you’ll experience less errors that can result in supply chain delays, such as backorders or incorrect shipments. And of course, with a supply chain that runs smoothly and efficiently, your warehouse makes more profits.

Whether your goals include reduced labor costs, improved efficiency, error reduction, or optimizing processes as a whole, a warehouse rack labeling solution is an important piece of the puzzle. Contact Camcode today to learn more about how our custom warehouse rack label solutions can transform your warehouse operations.

“We found Camcode’s barcode system to be the most cost-effective and efficient solution.”

Things move fast around here, and we needed a barcode system that provided easy and accurate scanning.

“We went from virtually one location to 506 locations thanks to Camcode labels.”

“We can delineate where items are stored and have better management and control by location.”

Discover Warehouse Management Insights

Explore our case studies, blog, buyer’s guides, specification sheets and more — and start learning more about the driving efficiencies with warehouse labeling systems. View All Resources ›

Frequently Asked Questions About Warehouse Rack Labels

Warehouse rack labels contain a barcode that can be scanned using a barcode scanner or barcode app, as well as a series of human-readable characters (numbers, letters, special characters) that represent information such as the location identifier, the picking zone, the product category, or other details.

Warehouse racking labels may also be color-coded to provide additional information.

To label a rack in a warehouse, identify the location based on your location numbering system and determine what other information should be conveyed (such as the product type, picking zone, etc.). Work with a label manufacturer like Camcode to select the best warehouse rack labels for your application (such as cold-storage rack labels, multi-level rack labels, etc.).

Finally, apply the warehouse racking label to the appropriate location with adhesive or mechanical attachment, depending on the type of rack label.

There are dozens of different types of warehouse labels, but they can generally be categorized by a few primary types. These include warehouse floor labels, warehouse rack labels, warehouse signs, cold storage warehouse rack labels, pallet, container, and tote labels, and outdoor warehouse labels and signs.

LPN labels are used to identify individual pallets within a warehouse. These can be linked to warehouse racking labels that indicate where pallets containing a certain product type are stored within the racking system.

This allows warehouse associates to scan rack labels to locate certain products and scan both the LPN label and rack label to identify the appropriate pallet storage location.

Upgrade & Evolve with a Scalable Warehouse Labeling System

Find out how a custom warehouse labeling system helps you evolve warehouse management for the digital age.