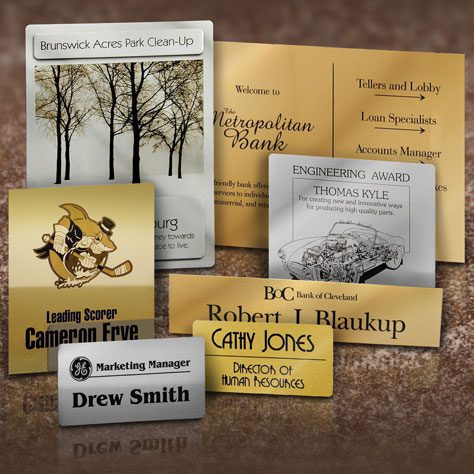

Industrial Metal Barcode Labels and Tags

Identification with unmatched durability for industrial environments.

Labels With Industrial Durability

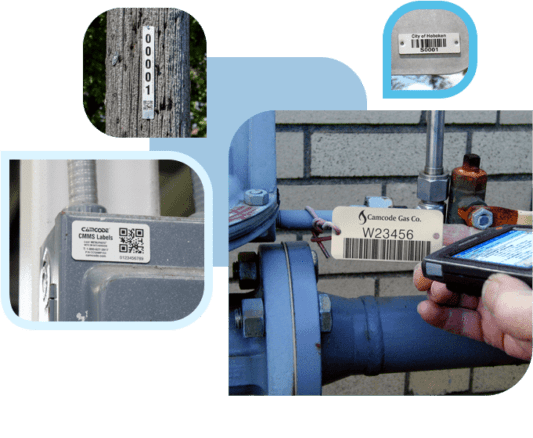

Camcode has durable barcode labels for every industrial application. These plastic and metal barcode labels and tags perform in the harshest environments, including chemicals, cleaning processes, painting processes, outdoor exposure and temperatures up to 1200°F. Our most widely used products are listed below. Contact us and we will design the right barcode label for your application!

We are experts in receiving label requirements electronically, managing multiple shipments of products, and shipping labels to meet JIT production systems. Our ability to manage sequential numbering of multiple shipments is proven and guaranteed, making Camcode the top metal barcode label manufacturer.

Explore Our Most Popular Durable Label Products

Explore our range of asset tag products and metal barcode labels, designed for every industrial application. Don’t see what you need? Our product development team is on standby to design and build your perfect label.

Need Labels Designed for a Specfic Harsh Condition?

Camcode has asset tracking options engineered for all extreme operating conditions.

Get a Free Asset Label Evaluation Kit

Request a free asset label sample kit today and we will send you a kit to test our extremely durable labels in your own operating environment.

Discover Insights for Industrial Asset Tracking

Explore our blog, buyer’s guides, specification sheets and more — and start learning more about the complex world of asset tracking. View All Resources ›

Frequently Asked Questions About Metal Barcode Labels & Tags

Metal barcode labels typically are the most durable barcodes for permanently labeling assets. However, the most durable barcode for an application depends on the operating environment of the asset (and subsequently the environmental conditions the barcode must withstand).

Metalphoto® anodized aluminum is considered the most durable printed aluminum substrate and is the most frequently specified label material for U.S. Department of Defense applications. Most Metalphoto® anodized aluminum have an expected exterior lifespan of 20+ years and can withstand prolonged exposure to UV, outdoor weather, abrasion, chemicals and solvents, and extreme temperatures.

In certain applications, other materials may be more suitable. For instance, stainless steel barcodes are often used for food processing applications due to stainless steel’s corrosion resistance and ease of cleaning.

Besides metal barcode labels, there are many different types of barcode tags, which can be categorized by the substrate material, application, imaging process, durability characteristics, and other factors.

For instance, different types of barcode labels based on materials include Metalphoto® photosensitive anodized aluminum barcode labels, Durablack®, Alumamark®, Teflon® Coated Paint Resistance, XHT Metalphoto®, stainless steel, brass, tesa® Secure™ UID labels, polyester, and vinyl.

These types of barcode labels can be further identified based on other factors such as the application or industry.

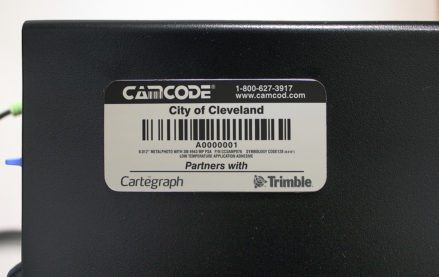

You might also classify barcode labels based on use case, such as warehouse barcode labels, inventory tracking barcode labels (part of a comprehensive inventory tracking system), equipment tracking barcode labels (part of a comprehensive equipment tracking system), CMMS maintenance management barcode labels, inspection and audit tracking barcode labels, manufacturing work-in-progress barcode labels, facilities management barcode labels, compliance marking barcode labels, security barcode labels, harsh environment tracking labels, consumer product tracking barcode labels, and general asset tracking barcode labels.

Metalphoto® photosensitive anodized aluminum barcode labels are the best barcodes for asset tracking in most applications. Metalphoto metal barcode labels can withstand indoor and outdoor conditions such as UV, chemicals, solvents, abrasion, extreme temperatures, humidity, salt spray, and other harsh conditions.

These metal barcode labels have an expected lifespan of 20+ years in the harshest indoor and outdoor environments.

Linear (1D) barcodes and two-dimensional (2D) barcodes (also known as matrix barcodes) are the two main types of barcodes. There are more than 30 primary barcode categories overall and various barcode symbologies for different use cases.

1D barcodes are either numeric-only (only using numbers 0-9) or alpha-numeric (which can include numbers, letters, and sometimes special characters) represented by a series of vertical lines in varying lengths. 2D barcodes include a series of squares that represent different characters and have a much higher density than 1D barcodes, supporting more than 7,000 characters in a single barcode.

“We needed the ‘Swiss Army Knife’ of tags.”

“It was necessary to have an asset tag that could withstand the outdoor elements, yet was simple enough to meet basic tracking needs. We achieved both with Camcode’s asset tags.”

“Camcode took the time to understand our needs.”

“Camcode took the time to understand our needs and offer durable solutions that will last throughout the different areas of our warehouse.”

Keep Operations Efficient with Durable Metal Barcode Labels & Asset Tracking Tags

If you’re having trouble finding the ideal tracking solution for your project or organization, build it with Camcode. Talk to our team today.